Description

Product Overview

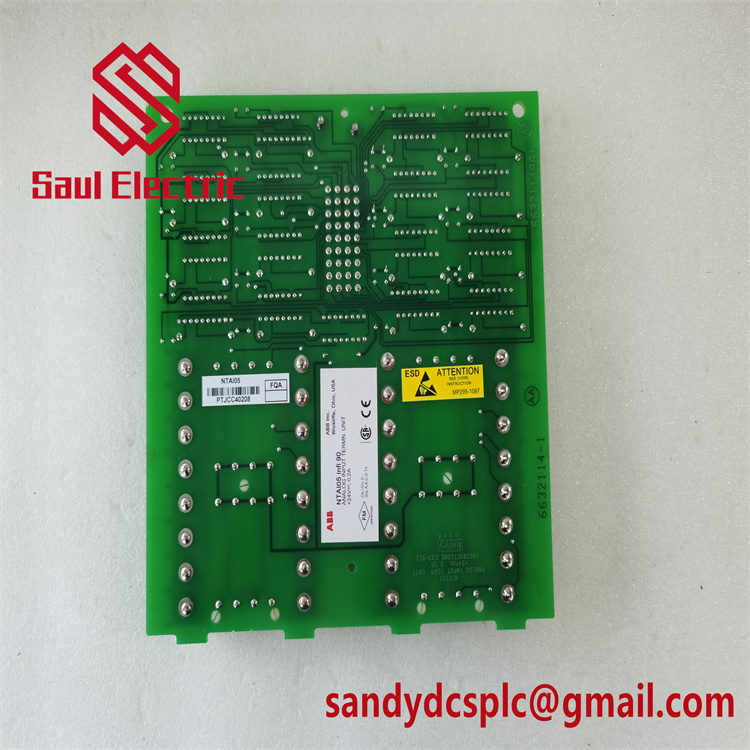

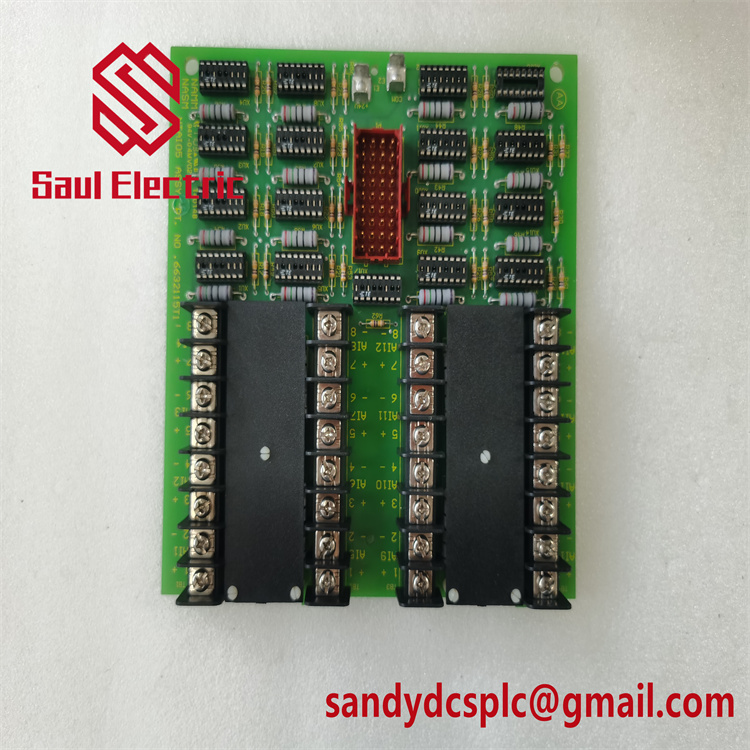

The ABB NTLS01 is a high-reliability logic station termination unit designed for ABB’s Bailey INFI 90 and Symphony Harmony distributed control systems (DCS). Serving as a critical interface between field devices and control systems, the ABB NTLS01 enables seamless integration of digital signals while delivering advanced signal conditioning, isolation, and diagnostic capabilities. With support for 8 channels of digital inputs (12–24 V DC) and Modbus RTU/Profibus DP communication protocols, this termination unit is ideal for applications requiring reliable connectivity in industrial automation environments .

Engineered with a modular design, the ABB NTLS01 supports compatibility with ABB’s IMFEC12 analog input sub-modules and IMQRS02 digital I/O modules, allowing flexible expansion of I/O capacity. Its rugged IP20-rated enclosure with conformal coating ensures operation in harsh conditions, including extreme temperatures (-40°C to +85°C) and high electromagnetic interference (EMI) . By providing surge protection and signal filtering, the ABB NTLS01 ensures accurate data transmission to DCS controllers, enhancing system stability and reducing downtime in mission-critical processes.

As part of ABB’s industrial automation portfolio, the ABB NTLS01 plays a pivotal role in modernizing control systems by enabling real-time monitoring and precise control of field devices. Its DIN rail mounting and hot-swappable design streamline installation and maintenance, making it a cost-effective solution for power generation, oil & gas, water treatment, and manufacturing sectors. With global technical support and a 12-month warranty, the ABB NTLS01 combines cutting-edge technology with ABB’s renowned reliability to meet the demands of industrial automation .

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB NTLS01 |

| Manufacturer | ABB |

| Product Type | Logic Station Termination Unit |

| Input Channels | 8 digital (12–24 V DC) |

| Communication Protocols | Modbus RTU, Profibus DP |

| Power Supply | 24 V DC ±10% |

| Physical Dimensions | 100 mm (L) × 60 mm (H) × 40 mm (W) |

| Weight | 0.2 kg |

| Operating Temperature | -40°C to +85°C |

| Humidity | 0–95% non-condensing |

| Mounting | 35 mm DIN rail or rack-mountable |

| Certifications | CE, UL 508, IEC 61131-2 (EMC) |

| Signal Isolation | Isolated signal paths for digital channels |

Key Features and Advantages

Modular Signal Handling: The ABB NTLS01 supports 8 channels of digital inputs (12–24 V DC), ensuring compatibility with a wide range of field devices such as proximity switches, limit switches, and relays. Its configurable signal conditioning includes overvoltage protection and noise filtering, reducing the need for external converters .

Rugged Industrial Design: Built with an IP20-rated enclosure and conformal coating, the ABB NTLS01 withstands dust, moisture, and EMI in harsh industrial environments. Its extended temperature range (-40°C to +85°C) makes it suitable for outdoor installations and high-temperature applications like power plants and chemical processing facilities .

Enhanced Reliability: The unit includes surge protection and signal isolation to prevent ground loops and electrical noise, ensuring stable data transmission. Diagnostic LEDs provide real-time status monitoring, allowing quick identification of signal loss, overrange conditions, or module faults .

Flexible Integration: Compatible with ABB’s IMFEC12 and IMQRS02 sub-modules, the ABB NTLS01 seamlessly integrates with INFI 90 and Symphony Harmony systems. It also supports third-party devices via Modbus RTU through gateway modules like the ABB TB821, enabling hybrid control system configurations .

Ease of Maintenance: Hot-swappable modules and screw-terminal connections simplify field wiring and replacement, minimizing downtime. The unit’s DIN rail mounting and compact design optimize space in control panels, while ABB’s Control Builder M software facilitates remote configuration and firmware updates .

Application Areas

Power Generation: The ABB NTLS01 monitors critical parameters in thermal power plants, such as turbine status via digital inputs and boiler interlock signals. Its redundancy support ensures reliable operation in emergency shutdown systems .

Oil & Gas: In offshore platforms and refineries, the ABB NTLS01 processes digital outputs from smart transmitters to track wellhead conditions and manage pump motor status. Its rugged design ensures durability in corrosive and high-vibration environments .

Water Treatment: The unit converts digital signals from level sensors and valve position switches to standardized outputs for centralized SCADA monitoring. It also manages pump motor control signals to optimize energy efficiency and detect equipment faults .

Manufacturing: In semiconductor and food processing plants, the ABB NTLS01 connects RTDs and vibration sensors to DCS controllers, enabling predictive maintenance. Its digital outputs drive actuators and relays in automated production lines .

Related Products

- IMFEC12: 15-channel analog input sub-module for 4–20 mA signals, directly compatible with the ABB NTLS01 .

- IMQRS02: Digital I/O sub-module for 24 V DC signals, expanding the ABB NTLS01’s digital control capabilities .

- NK TU 01: Field termination unit for mounting the ABB NTLS01 in 19” racks, ensuring organized cabling .

- TB821: Modbus RTU-to-Ethernet gateway for integrating the ABB NTLS01 with third-party PLCs .

- IMFEC12: Analog input sub-module supporting thermocouple/RTD inputs, complementing the ABB NTLS01’s temperature monitoring capabilities .

Installation and Maintenance

Installation Preparation:

- DIN Rail Mounting: Secure the ABB NTLS01 to a 35 mm DIN rail using included brackets, ensuring proper alignment with adjacent modules.

- Wiring: Connect field devices to the unit’s screw terminals, following ABB’s wiring diagrams for digital signal polarity. Use shielded cables (e.g., NKAS01-15) to minimize EMI .

- Configuration: Set signal types and ranges via DIP switches on the connected sub-module (e.g., IMFEC12) or through Control Builder M software. Verify loop power (24 V DC) and ground connections using front-panel LEDs .

Maintenance Recommendations:

- Hot-Swap Replacement: Replace faulty modules without system shutdown by disconnecting power, removing the old module, and inserting a new ABB NTLS01.

- Calibration: Perform annual signal accuracy checks using a multimeter, adjusting offsets as needed. ABB’s calibration tools ensure compliance with industry standards .

- Firmware Updates: Regularly update firmware via Control Builder M to support new sensor types and enhance diagnostic features.

- ESD Protection: Use ABB’s Field Static Kit (e.g., part number 1948385A1) during handling to prevent electrostatic discharge damage .

Product Assurance

The ABB NTLS01 is backed by a 12-month warranty covering manufacturing defects, with extended warranties available for critical applications. ABB’s global service network provides 24/7 technical support for commissioning, troubleshooting, and custom integration. Stocked in ABB’s Xiamen and Singapore hubs, the ABB NTLS01 ensures fast delivery (3–5 days for Taiwan orders) and immediate replacement in case of emergencies .

With rigorous testing against EMC and environmental standards, the ABB NTLS01 delivers unmatched reliability in electrically noisy or extreme conditions. ABB’s commitment to quality and innovation makes it the preferred choice for industrial automation professionals seeking high-performance, future-proof solutions.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com