Description

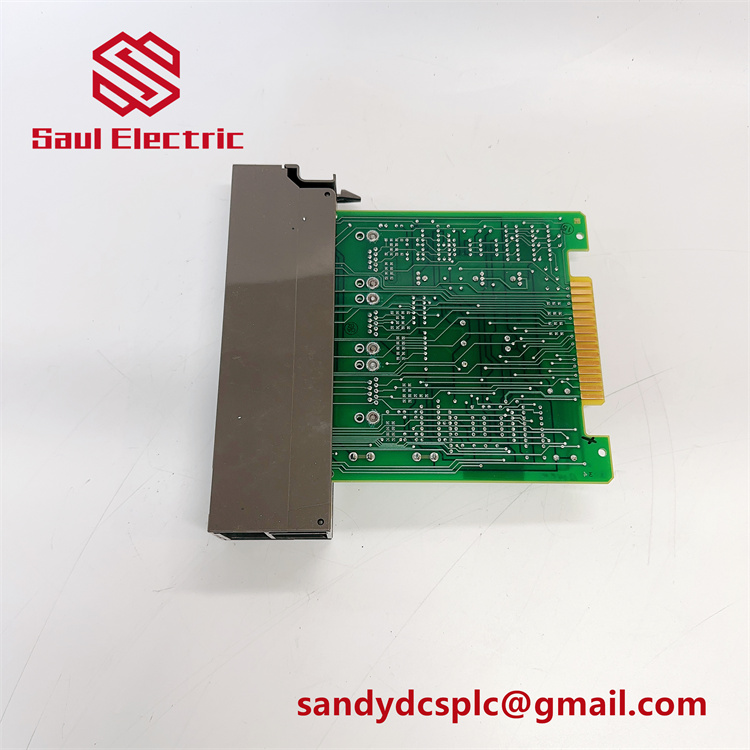

ABB NPCT-01C Pulse Counter and Timer Module

The ABB NPCT-01C is a high-precision industrial automation module designed for pulse counting, timing, and motion control applications in harsh environments. Engineered for reliability and flexibility, it serves as a critical component in distributed control systems (DCS) and programmable logic controllers (PLCs), particularly within ABB’s AC 800M and S800 I/O architectures. Below is a detailed breakdown of its features, technical specifications, and applications:

Core Functionality

-

Pulse Counting & Timing

- Dual-channel design: Simultaneously processes two independent pulse inputs (e.g., from encoders, flow meters, or proximity sensors) with a frequency range of 0–100 kHz 14.

- High precision: Achieves timing accuracy of ±0.1% of setting +1ms, suitable for critical operations like batch processing or conveyor speed monitoring 14.

- Programmable modes: Supports up/down counting, event-triggered timing, and frequency measurement, configurable via ABB’s Automation Builder software 5.

-

Signal Handling & Communication

- Relay outputs: Two isolated relay outputs for control signals (e.g., triggering alarms or actuators) 14.

- RS-485 interface: Enables bidirectional communication with HMIs, SCADA systems, or PLCs (e.g., Siemens S7) for remote parameter adjustment and data logging 5.

- HART compatibility: Integrates with smart field devices for advanced diagnostics and predictive maintenance 3.

-

Rugged Industrial Design

- IP20-rated enclosure: Protects against dust and minor impacts, with conformal coating on circuit boards to resist moisture and corrosion in offshore or mining environments 16.

- Wide temperature range: Operates reliably from -20°C to +70°C, with storage tolerance up to +85°C 1420.

- Hot-swappable: Allows module replacement without system downtime, minimizing production interruptions 3.

Technical Specifications

| Parameter | Value |

|---|---|

| Model | NPCT-01C |

| Manufacturer | ABB |

| Power Supply | 24V DC ±10% (250 mA max.) 1416 |

| Physical Dimensions | 41 mm (W) × 264 mm (H) × 94 mm (D) 14 |

| Weight | 1.0 kg |

| Input Channels | 2 (isolated, 0–100 kHz) 14 |

| Outputs | 2 relay outputs (250V AC/30V DC, 5A max.) 14 |

| Communication | RS-485, HART 7 35 |

| Compliance | CE, UL, IEC 61131-2 (EMC) 14 |

| Mounting | 35 mm DIN rail with front-panel LED diagnostics 14 |

Applications

-

Industrial Manufacturing

- Motion control: Monitors conveyor belt speed via encoder feedback to ensure precise material handling in automotive or food processing plants 514.

- Batch processing: Triggers valves or motors based on pulse counts to control chemical dosing or packaging machinery 16.

-

Power Generation

- Turbine monitoring: Measures rotational speed of generators using pulse inputs from proximity sensors, enabling real-time performance optimization 14.

- Grid synchronization: Coordinates timing signals for seamless integration of renewable energy sources into the power grid 3.

-

Oil & Gas

- Flow metering: Counts pulses from turbine flow meters to track liquid/gas volumes in pipelines, supporting custody transfer applications 516.

- Rotary equipment control: Provides encoder feedback for drill rigs or pumps, ensuring safe and efficient operation 14.

-

Water Treatment

- Pump control: Adjusts pump speed based on flow rate measurements to maintain optimal pressure in filtration systems 35.

Compatibility & Integration

- ABB Systems:

- AC 800M DCS: Integrates with CI845 Ethernet FCI modules for communication with controllers, supporting up to 192 Select I/O channels 3.

- S800 I/O: Works seamlessly with ABB’s distributed I/O system for cost-effective, modular automation solutions 1.

- Third-Party Devices:

- PLCs: Connects to Siemens S7, Rockwell ControlLogix, or Mitsubishi Q-Series via RS-485 for hybrid control systems 5.

- SCADA/HMI: Exchanges data with Wonderware, WinCC, or Ignition platforms for centralized monitoring 14.

Installation & Maintenance

-

Setup

- DIN rail mounting: Simple snap-in installation with front-panel LEDs indicating power, communication, and fault status 14.

- Configuration: Programmed via ABB’s Automation Builder software, supporting ladder logic (LD), function block diagram (FBD), and structured text (ST) 1314.

-

Maintenance

- Hot-swappable design: Replace modules without system shutdown, reducing MTTR (mean time to repair) 3.

- Firmware updates: Remotely update via Automation Builder to enhance functionality or address security patches 14.

- Annual inspections: Verify terminal connections and clean dust using compressed air to maintain optimal performance 16.

Regional Support & Availability

- Taiwan: Authorized distributor Chuwei Technology (Kaohsiung) provides localized technical support and spare parts 911.

- Global Inventory: Stock available in Xiamen, China, with 3–5-day delivery to Taiwan via DHL/FedEx 911.

- Warranty: 12-month warranty covering defects in materials/workmanship 11.

Related Products

-

ABB AC 800M Series:

- CI845 Ethernet FCI Module: Enables communication between NPCT-01C and AC 800M controllers 3.

- AI815 Analog Input Module: Expands system capabilities for temperature or pressure monitoring 4.

-

HART Devices:

- ABB 267B6293P0010 Smart Pressure Transmitter: Integrates with NPCT-01C for real-time process optimization 3.

-

Expansion Modules:

- NICS01 Control I/O Termination Module: Extends I/O capacity for analog/digital signals in complex systems 3.

Product Assurance

ABB guarantees the NPCT-01C with rigorous testing to meet international standards. Its EMC protection and wide temperature range ensure reliability in electrically noisy or extreme environments. For mission-critical applications, ABB’s predictive maintenance services further enhance system uptime 1420.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com