Description

Product Overview

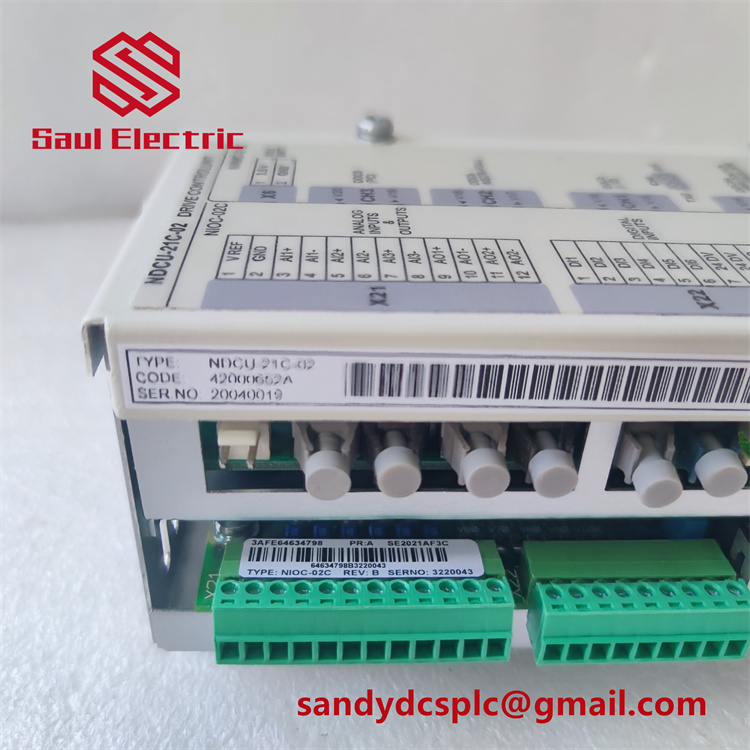

The ABB NDCU-33CX 3AUA0000052751 is a high-performance drive control unit (DCU) designed for advanced motor control in industrial automation systems. As a core component of ABB’s ACS880 Multidrive platform, this unit integrates seamlessly with ABB’s drive systems to deliver precise, reliable control for applications such as pumps, fans, compressors, and conveyors 37.

The ABB NDCU-33CX 3AUA0000052751 is a high-performance drive control unit (DCU) designed for advanced motor control in industrial automation systems. As a core component of ABB’s ACS880 Multidrive platform, this unit integrates seamlessly with ABB’s drive systems to deliver precise, reliable control for applications such as pumps, fans, compressors, and conveyors 37.

Featuring sensorless vector control and built-in safety functions, the NDCU-33CX ensures optimal performance and energy efficiency across a wide power range (0.75 kW to 250 kW) and voltage range (380–480V AC) 3. Its 24V DC power supply and RS-485 communication interface enable flexible integration with PLCs and other industrial devices, while galvanic isolation and EMI/RFI shielding protect against electrical noise in harsh environments 7. With hot-swappable functionality and front-panel LED diagnostics, the NDCU-33CX minimizes downtime during maintenance, making it ideal for mission-critical operations in industries like oil and gas, water treatment, and manufacturing 37.

The NDCU-33CX supports Modbus RTU communication via an optional adapter, allowing real-time monitoring and control of drive parameters. Its compact design (27.5 x 11.5 x 8.5 cm) and DIN rail mounting facilitate easy installation in space-constrained environments, while IP20 protection safeguards against dust and minor impacts 7. By combining high precision with rugged durability, this module enhances system efficiency and reduces operational costs across diverse industries.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | NDCU-33CX 3AUA0000052751 |

| Manufacturer | ABB |

| Product Type | Drive Control Unit (DCU) |

| Input Voltage | 24V DC ±10% |

| Power Range | 0.75 kW to 250 kW |

| Voltage Range | 380–480V AC |

| Frequency Range | 0.5–600 Hz |

| Output Current | Up to 420 A |

| Weight | 1.5 kg |

| Compliance | CE, UL |

| Operating Temperature | -20°C to +60°C |

| Physical Dimensions | 275 mm (width) x 115 mm (depth) x 85 mm (height) |

| Mounting Type | DIN rail (TS35/7.5 or TS35/15) |

| Communication | RS-485, Modbus RTU (via optional adapter) |

| Control Technology | Sensorless vector control, built-in brake chopper |

| Safety Features | Safe Torque Off (STO), overvoltage protection |

| LED Indicators | Power status, communication activity, fault alerts |

Key Features and Advantages

High-Precision Motor Control:

The NDCU-33CX employs sensorless vector control to achieve accurate speed and torque regulation without external sensors, reducing system complexity and cost. Its built-in brake chopper ensures safe and reliable stopping of high-inertia loads, critical for applications like conveyor belts and pumps 3.

The NDCU-33CX employs sensorless vector control to achieve accurate speed and torque regulation without external sensors, reducing system complexity and cost. Its built-in brake chopper ensures safe and reliable stopping of high-inertia loads, critical for applications like conveyor belts and pumps 3.

Flexible Communication:

With RS-485 and Modbus RTU support, the NDCU-33CX integrates seamlessly with PLCs, HMIs, and other industrial devices. This enables real-time data exchange for predictive maintenance and energy optimization, enhancing overall system efficiency 7.

With RS-485 and Modbus RTU support, the NDCU-33CX integrates seamlessly with PLCs, HMIs, and other industrial devices. This enables real-time data exchange for predictive maintenance and energy optimization, enhancing overall system efficiency 7.

Rugged Industrial Design:

Rated for -20°C to +60°C operation and featuring IP20 protection, the NDCU-33CX withstands extreme temperatures, dust, and vibrations. Galvanic isolation and EMI/RFI shielding ensure signal integrity in electrically noisy environments, such as manufacturing floors and power plants 7.

Rated for -20°C to +60°C operation and featuring IP20 protection, the NDCU-33CX withstands extreme temperatures, dust, and vibrations. Galvanic isolation and EMI/RFI shielding ensure signal integrity in electrically noisy environments, such as manufacturing floors and power plants 7.

Modular Compatibility:

Designed as a drop-in replacement for legacy ABB systems, the NDCU-33CX works with ACS880 drives and DCS800 series platforms. Its hot-swappable design allows maintenance without system downtime, while front-panel LEDs provide instant fault diagnosis 37.

Designed as a drop-in replacement for legacy ABB systems, the NDCU-33CX works with ACS880 drives and DCS800 series platforms. Its hot-swappable design allows maintenance without system downtime, while front-panel LEDs provide instant fault diagnosis 37.

Advanced Safety Functions:

The NDCU-33CX includes Safe Torque Off (STO) and overvoltage protection, complying with international safety standards (e.g., IEC 61800-5-2). These features protect personnel and equipment in hazardous environments, such as oil refineries and water treatment plants 3.

The NDCU-33CX includes Safe Torque Off (STO) and overvoltage protection, complying with international safety standards (e.g., IEC 61800-5-2). These features protect personnel and equipment in hazardous environments, such as oil refineries and water treatment plants 3.

Application Areas

The NDCU-33CX 3AUA0000052751 excels in industries requiring reliable motor control and energy optimization:

- Oil and Gas: Drilling rigs, pipeline compressors, and offshore platforms, where its wide temperature range and safety features ensure operation in hazardous conditions 3.

- Water Treatment: Filtration systems, wastewater pumps, and irrigation systems, leveraging sensorless vector control for precise flow and pressure regulation 3.

- Manufacturing: Conveyor belts, robotic systems, and packaging machinery, where real-time communication and hot-swappable design minimize downtime 7.

- Power Generation: Fans, pumps, and turbines in thermal and renewable energy plants, optimizing energy consumption and reducing maintenance costs 3.

- Mining and Metals: Ore crushers, conveyor systems, and material handling equipment, ensuring safe and efficient operation in dusty, high-vibration environments 3.

Related Products

- ABB ACS880 Drive Series: High-performance drives compatible with the NDCU-33CX for motor control and energy optimization.

- ABB NIDU-02C: Digital input/output module for expanding system connectivity.

- ABB NIOC-02C: I/O communication module for integrating the NDCU-33CX with remote devices.

- ABB RMBA-01: Modbus adapter module for enabling Modbus RTU communication with the NDCU-33CX.

- ABB 3BSE017427R1: Replacement kit for drive system upgrades, including the NDCU-33CX.

- ABB S800 I/O Modules: Distributed I/O units for extending system functionality.

Installation and Maintenance

Installation Preparation:

- Mounting: Securely install the NDCU-33CX on a DIN rail using 2.5–4 mm² cables. Ensure proper alignment with adjacent modules and drives.

- Cabling: Connect the 24V DC power supply and RS-485 communication cables. Use shielded twisted-pair cables to minimize interference.

- Configuration: Use ABB’s DriveWindow software to set motor parameters, communication protocols, and safety functions.

Maintenance Recommendations:

- Routine Checks: Inspect terminals quarterly for loose connections or corrosion. Clean dust using a dry cloth and compressed air.

- LED Monitoring: Use front-panel indicators to identify faults (e.g., overvoltage, communication errors). Replace faulty modules immediately.

- Firmware Updates: Periodically check ABB’s online support portal for firmware updates to access new features and security patches.

- Redundancy Testing: For critical applications, test redundant configurations annually to ensure failover capability.

Product Assurance

ABB guarantees the NDCU-33CX 3AUA0000052751 with a 1-year warranty, covering defects in materials and workmanship. The unit undergoes rigorous testing to meet international safety standards, ensuring long-term reliability. Customers benefit from ABB’s global technical support network, offering 24/7 assistance for troubleshooting and system optimization. With spot inventory and 3–5-day delivery commitments, ABB ensures rapid deployment to minimize downtime 716.

For localized support, ABB’s service centers in Kaohsiung, Taiwan provide on-site maintenance and repairs, leveraging ABB’s global expertise to address regional customer needs. This combination of high-performance control, responsive service, and proven reliability makes the NDCU-33CX 3AUA0000052751 a trusted choice for industrial drive system automation.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com