Description

Product Overview

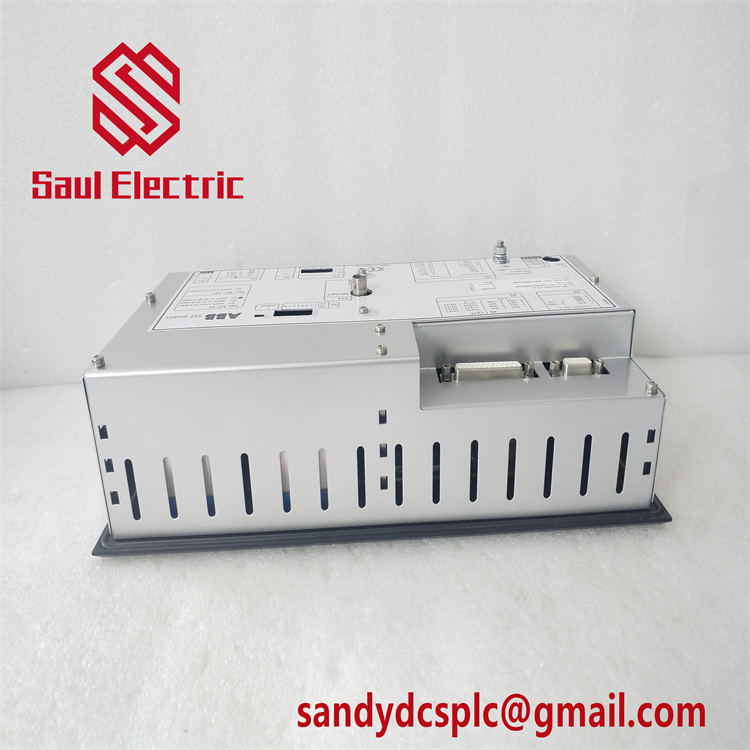

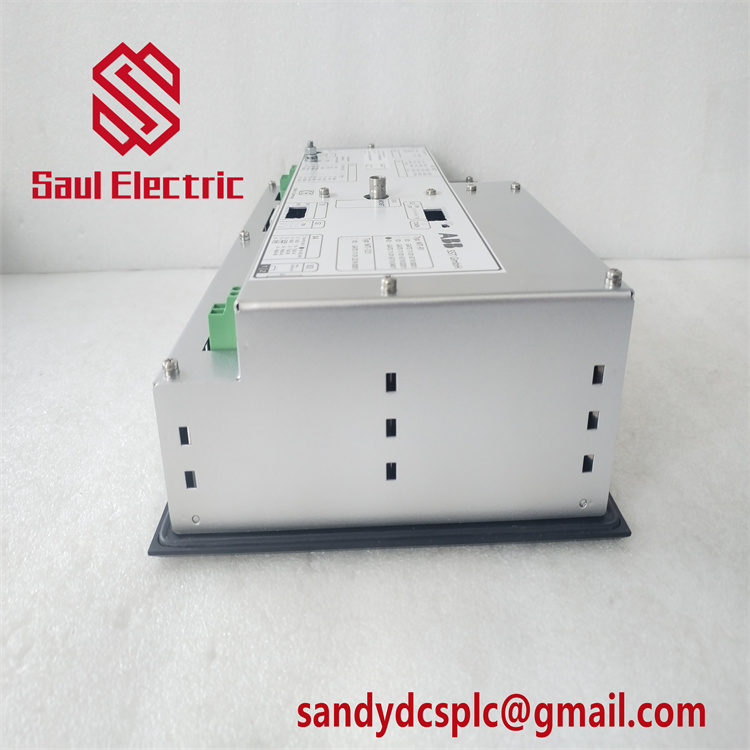

The ABB MT-91-ARC FP A is a high-reliability operator panel designed for industrial automation systems, specifically engineered to control and monitor ABB’s ACS 800 drives . It features a backlit LCD display, a tactile keypad, and function keys for intuitive operation in harsh environments. Built with IP65/IP66 protection , the module withstands dust, moisture, and vibrations, making it suitable for oil and gas, power generation, and chemical processing applications .

As part of ABB’s SC300E Triguard platform, the MT-91-ARC FP A supports multi-protocol communication (e.g., RS-422/485) and integrates with PLCs, sensors, and pulse servo devices for mission-critical control tasks . Its hot-swap capability and front-panel LEDs for real-time status monitoring (Tx/Rx activity, circuit health) streamline maintenance and reduce downtime .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Communication Interfaces | RS-422/485, 4x RS232 (full-duplex, 9600/19200 baud) |

| Supported Protocols | RS232-C, Modbus RTU (via software configuration) |

| Power Supply | 24V DC (19.2–30V DC) |

| Current Rating | 1A |

| Protection Level | IP65/IP66 (EN 60529) |

| Operating Temperature | -20°C to +50°C |

| Physical Dimensions | 342 mm (width) x 259 mm (height) x 742 mm (depth) |

| Weight | 2.2–3.6 kg |

| Compliance | CE, UL, ATEX Class 1 Zone 2 |

| Mounting Type | DIN rail or panel-mount |

| Data Logging | Stores up to 20 communication events with timestamps |

| Isolation | Optocoupler isolation for RS232 ports |

Key Features and Advantages

Multi-Protocol Flexibility:

The MT-91-ARC FP A supports RS232/422/485 and configurable Modbus RTU, enabling seamless integration with third-party devices and legacy systems. Its four independent ports allow simultaneous communication with multiple field devices, reducing dependency on external converters .

The MT-91-ARC FP A supports RS232/422/485 and configurable Modbus RTU, enabling seamless integration with third-party devices and legacy systems. Its four independent ports allow simultaneous communication with multiple field devices, reducing dependency on external converters .

Rugged Industrial Design:

With IP65/IP66 protection and EMI/RFI filtering, the module withstands extreme temperatures, vibrations, and electromagnetic interference. Its galvanic isolation (1kV) safeguards signal integrity in high-noise environments .

With IP65/IP66 protection and EMI/RFI filtering, the module withstands extreme temperatures, vibrations, and electromagnetic interference. Its galvanic isolation (1kV) safeguards signal integrity in high-noise environments .

Hot-Swap Capability:

The module supports hot-swappable replacement without system shutdown, minimizing downtime during maintenance. Front-panel LEDs provide real-time diagnostics for quick fault identification .

The module supports hot-swappable replacement without system shutdown, minimizing downtime during maintenance. Front-panel LEDs provide real-time diagnostics for quick fault identification .

High-Frequency Signal Handling:

Capable of receiving counting pulses up to tens of kHz, the MT-91-ARC FP A is ideal for motion control applications requiring precise encoder signal processing. It also features pulse output functionality for direct integration with servo systems .

Capable of receiving counting pulses up to tens of kHz, the MT-91-ARC FP A is ideal for motion control applications requiring precise encoder signal processing. It also features pulse output functionality for direct integration with servo systems .

Compliance and Safety:

Certified to ATEX Class 1 Zone 2 and CE/UL standards, the MT-91-ARC FP A is suitable for hazardous environments, ensuring compliance with global industrial regulations .

Certified to ATEX Class 1 Zone 2 and CE/UL standards, the MT-91-ARC FP A is suitable for hazardous environments, ensuring compliance with global industrial regulations .

Application Areas

The ABB MT-91-ARC FP A excels in high-reliability industrial applications:

- Oil and Gas: Controls pumps, valves, and compressors in offshore platforms and refineries, ensuring uninterrupted operation in explosive atmospheres.

- Power Generation: Manages SCADA systems in thermal and hydroelectric plants, optimizing grid stability and energy efficiency.

- Chemical Processing: Regulates reactors and distillation units in petrochemical facilities, adhering to strict safety protocols.

- Water Treatment: Monitors and controls pumps in wastewater treatment plants, ensuring compliance with environmental standards.

- Manufacturing: Connects robotics and conveyor systems in automotive and food processing facilities, enabling real-time monitoring and control.

Related Products

- ABB ACS 800 Drives: High-performance drives compatible with the MT-91-ARC FP A for motor control.

- ABB AC500 PLC Series: Scalable PLCs for complex automation tasks.

- ABB SC300E Triguard Modules: Redundant I/O modules for safety-critical systems.

- ABB EIU32.0 Ethernet/IP Adapter: Enables Ethernet communication for integration with modern industrial networks.

- ABB PDP32.0 PROFIBUS DP Module: Connects to PROFIBUS DP networks for seamless integration with PLCs and HMIs.

Installation and Maintenance

Installation Preparation:

- Power and Cabling: Verify 24V DC power supply (19.2–30V DC) and connect RS-422/485 cables to the rear J2 connector. Use the module’s mechanical coding blocks to prevent incorrect slot insertion .

- Configuration: Set baud rates (9600/19200) and port roles (master/slave) using ABB’s Tribuild software. Ensure ports 2 and 3 have matching baud rates for diagnostic purposes .

Maintenance Recommendations:

- Routine Checks: Inspect terminals for loose connections and corrosion. Clean dust using a dry cloth, avoiding solvents.

- LED Monitoring: Use front-panel LEDs to monitor Tx/Rx activity, circuit health, and online status. Replace faulty modules immediately.

- Firmware Updates: Regularly update firmware to address security vulnerabilities and improve compatibility with newer systems. ABB’s global technical support network offers 24/7 assistance for firmware updates .

- Redundancy Testing: Perform quarterly switchover tests for redundant configurations to ensure failover functionality.

Product Assurance

ABB guarantees the MT-91-ARC FP A with a 1-year warranty, covering defects in materials and workmanship. The module undergoes rigorous testing to meet international safety standards, ensuring long-term reliability in industrial environments. Customers benefit from ABB’s global technical support network, offering 24/7 assistance for troubleshooting, firmware updates, and system optimization. With spot inventory and 3–15-day delivery commitments, ABB ensures rapid deployment to minimize downtime .

For localized support, ABB’s service centers in Kaohsiung, Taiwan provide on-site maintenance and repairs, leveraging ABB’s global expertise to address regional customer needs .

This combination of rugged design, multi-protocol flexibility, and responsive service makes the ABB MT-91-ARC FP A a trusted choice for mission-critical industrial control applications.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com