Description

Product Overview

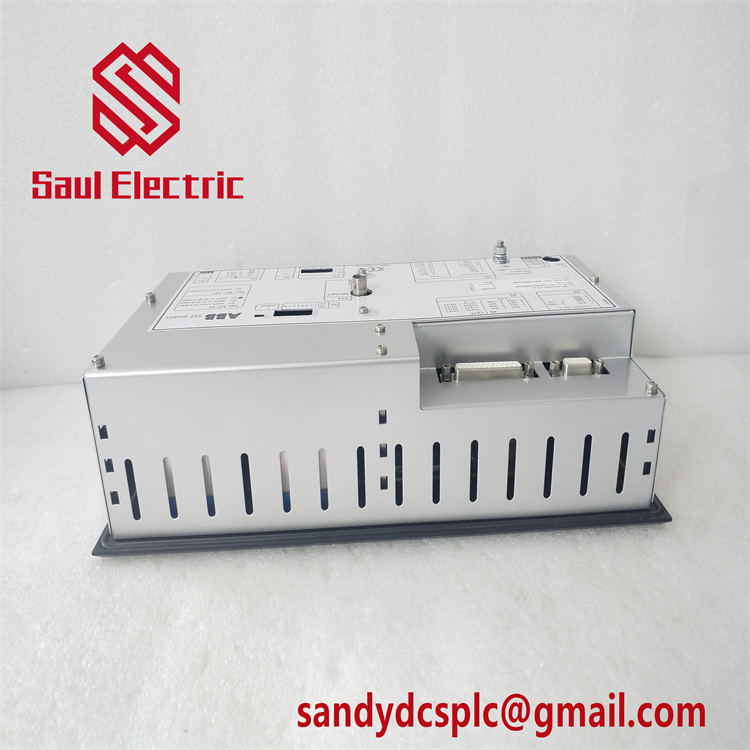

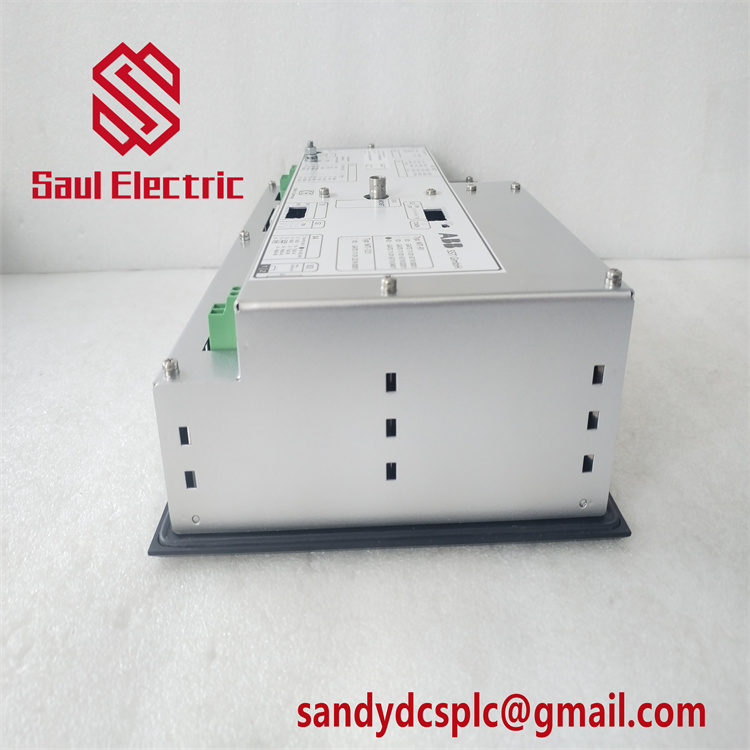

The ABB MSR04XI is a high-reliability serial communication module designed for Triguard SC300E safety-critical systems, offering seamless connectivity in industrial automation environments. Engineered for mission-critical applications such as oil refineries, power plants, and chemical processing, this module ensures robust data transmission in harsh conditions while adhering to IP67 and ATEX standards 1216.

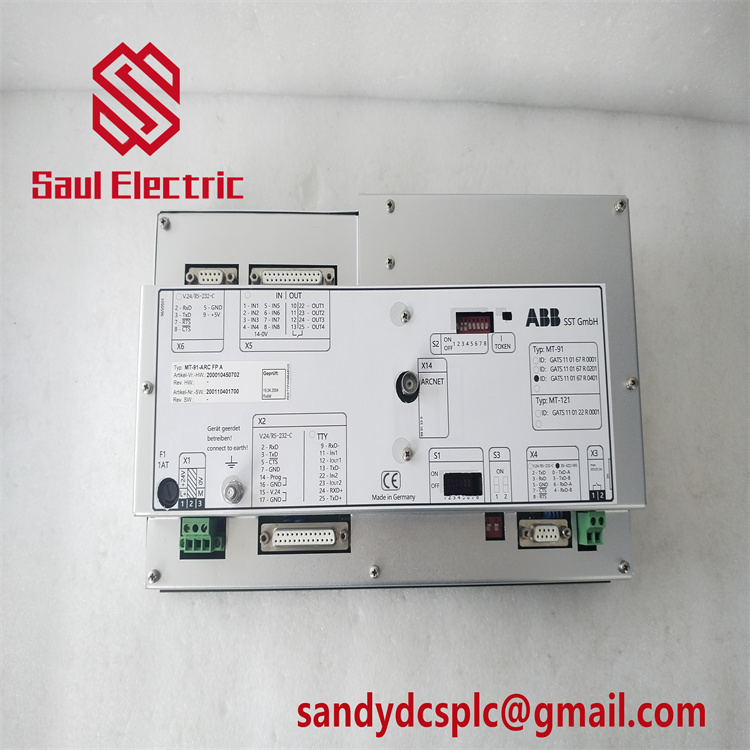

As part of the SC300E Triguard platform, the MSR04XI integrates triple-redundant circuitry and 2-out-of-3 voting logic, providing single-fault tolerance and continuous operation even in the event of component failure 1216. It supports four RS232 ports (0–3) with configurable baud rates (9600 or 19200) and galvanic isolation (1kV), enabling secure communication with remote devices like HMIs, sensors, and PLCs 1213. The module’s hot-swap capability and front-panel LEDs for real-time status monitoring (Tx/Rx activity, circuit health) streamline maintenance and reduce downtime 1320.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | MSR04XI |

| Manufacturer | ABB |

| Product Type | Serial Communication Module (Triguard SC300E Series) |

| Communication Interfaces | 4x RS232 (ports 0–3), full-duplex, 9600/19200 baud |

| Supported Protocols | RS232-C, Modbus RTU (via software configuration) 1216 |

| Power Supply | 24V DC (19.2–30V DC) |

| Current Rating | 1A |

| Protection Level | IP67 (EN 60529) |

| Operating Temperature | -20°C to +60°C |

| Physical Dimensions | 150 mm (width) x 100 mm (height) x 70 mm (depth) 113 |

| Weight | 1.3–1.5 kg 112 |

| Compliance | CE, UL, ATEX Class 1 Zone 2 |

| Mounting Type | DIN rail (requires installation in SC300E chassis slot 10 for primary module) 1216 |

| Redundancy Support | Triple-circuit redundancy with 2-out-of-3 voting |

| Data Logging | Stores up to 20 communication events with timestamps |

| Isolation | Optocoupler isolation for RS232 ports |

Key Features and Advantages

Safety-Critical Redundancy:

The MSR04XI employs triple-reduplicated circuitry and 2-out-of-3 voting logic, ensuring fault tolerance and continuous operation in safety-critical applications. This architecture meets the highest standards for systems requiring SIL 3 certification 1216.

The MSR04XI employs triple-reduplicated circuitry and 2-out-of-3 voting logic, ensuring fault tolerance and continuous operation in safety-critical applications. This architecture meets the highest standards for systems requiring SIL 3 certification 1216.

Multi-Protocol Flexibility:

While natively supporting RS232-C, the module can be configured for Modbus RTU via software, enabling integration with third-party devices. Its four independent ports allow simultaneous communication with multiple field devices, reducing dependency on external converters 1216.

While natively supporting RS232-C, the module can be configured for Modbus RTU via software, enabling integration with third-party devices. Its four independent ports allow simultaneous communication with multiple field devices, reducing dependency on external converters 1216.

Rugged Industrial Design:

With IP67 protection and EMI/RFI filtering, the MSR04XI withstands extreme temperatures, vibrations, and electromagnetic interference. Its galvanic isolation (1kV) safeguards signal integrity in high-noise environments 1213.

With IP67 protection and EMI/RFI filtering, the MSR04XI withstands extreme temperatures, vibrations, and electromagnetic interference. Its galvanic isolation (1kV) safeguards signal integrity in high-noise environments 1213.

Hot-Swap Capability:

The module supports hot-swappable replacement without system shutdown, minimizing downtime during maintenance. Front-panel LEDs provide real-time diagnostics for quick fault identification 1320.

The module supports hot-swappable replacement without system shutdown, minimizing downtime during maintenance. Front-panel LEDs provide real-time diagnostics for quick fault identification 1320.

Compliance and Safety:

Certified to ATEX Class 1 Zone 2 and CE/UL standards, the MSR04XI is suitable for hazardous environments, ensuring compliance with global industrial regulations 1216.

Certified to ATEX Class 1 Zone 2 and CE/UL standards, the MSR04XI is suitable for hazardous environments, ensuring compliance with global industrial regulations 1216.

Application Areas

The ABB MSR04XI excels in high-reliability industrial applications:

- Oil and Gas: Controls pumps, valves, and compressors in offshore platforms and refineries, ensuring uninterrupted operation in explosive atmospheres.

- Power Generation: Manages SCADA systems in thermal and hydroelectric plants, optimizing grid stability and energy efficiency.

- Chemical Processing: Regulates reactors and distillation units in petrochemical facilities, adhering to strict safety protocols.

- Water Treatment: Monitors and controls pumps in wastewater treatment plants, ensuring compliance with environmental standards.

- Mining and Metals: Supports communication between PLCs and heavy machinery in remote, dusty environments, enhancing operational efficiency.

Related Products

- ABB SC300E Triguard Modules: Redundant I/O modules for safety-critical systems.

- ABB AC500 PLC Series: Scalable PLCs compatible with the MSR04XI for complex automation tasks.

- ABB EIU32.0 Ethernet/IP Adapter: Enables Ethernet communication for integration with modern industrial networks.

- ABB PDP32.0 PROFIBUS DP Module: Connects to PROFIBUS DP networks for seamless integration with PLCs and HMIs.

- ABB MSR04X1: A non-redundant variant for general industrial applications with broader protocol support (e.g., PROFIBUS DP) 56.

- ABB S800 I/O Modules: High-performance distributed I/O units for seamless integration.

- ABB UMC100.3 Universal Motor Controller: Offers advanced motor management with Ethernet/IP support.

Installation and Maintenance

Installation Preparation:

- Chassis Compatibility: The MSR04XI requires installation in SC300E chassis slot 10 for primary communication functionality. Additional modules can be installed in other slots for expanded connectivity 1216.

- Power and Cabling: Verify 24V DC power supply (19.2–30V DC) and connect RS232 cables to the rear J2 connector. Use the module’s mechanical coding blocks to prevent incorrect slot insertion 1213.

- Configuration: Set baud rates (9600/19200) and port roles (master/slave) using ABB’s Tribuild software. Ensure ports 2 and 3 have matching baud rates for diagnostic purposes 1216.

Maintenance Recommendations:

- Routine Checks: Inspect terminals for loose connections and corrosion. Clean dust using a dry cloth, avoiding solvents.

- LED Monitoring: Use front-panel LEDs to monitor Tx/Rx activity, circuit health, and online status. Replace faulty modules immediately.

- Firmware Updates: Regularly update firmware to address security vulnerabilities and improve compatibility with newer systems.

- Redundancy Testing: Perform quarterly switchover tests for redundant configurations to ensure failover functionality.

Product Assurance

ABB guarantees the MSR04XI with a 1-year warranty, covering defects in materials and workmanship. The module undergoes rigorous testing to meet international safety standards, ensuring long-term reliability in industrial environments. Customers benefit from ABB’s global technical support network, offering 24/7 assistance for troubleshooting, firmware updates, and system optimization. With spot inventory and 3–15-day delivery commitments, ABB ensures rapid deployment to minimize downtime 111.

This combination of safety-critical redundancy, rugged design, and responsive service makes the ABB MSR04XI a trusted choice for mission-critical communication applications.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com