Description

Product Overview

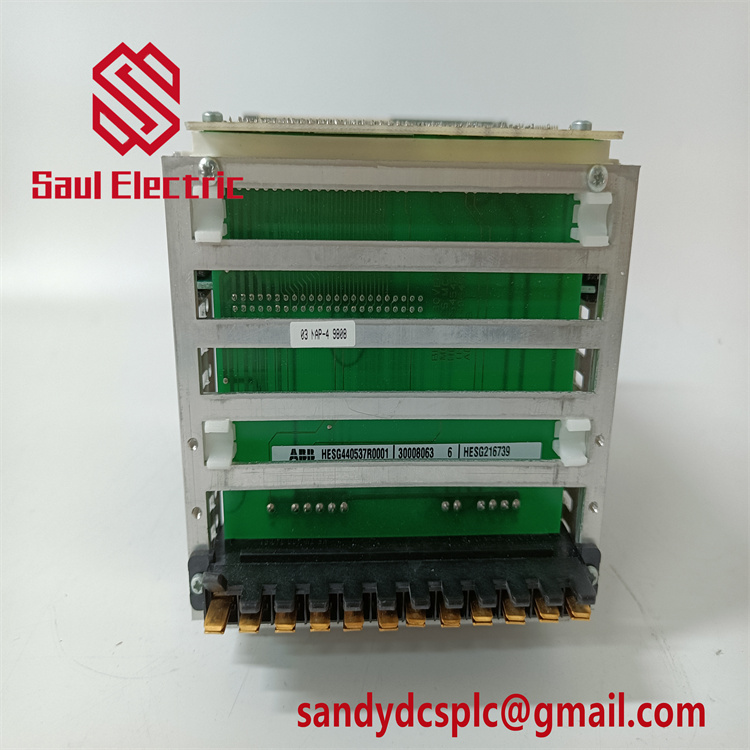

The ABB MR627 P89627-0-2333400-300-401-601-701 is a high-performance motor control unit (MCU) designed for industrial automation systems, specifically engineered for ABB’s S800 I/O platform. As a core component of distributed control systems (DCS), this module delivers precise motor control, comprehensive protection, and advanced diagnostic capabilities to ensure seamless operation in mission-critical applications such as conveyor systems, pumps, and compressors.

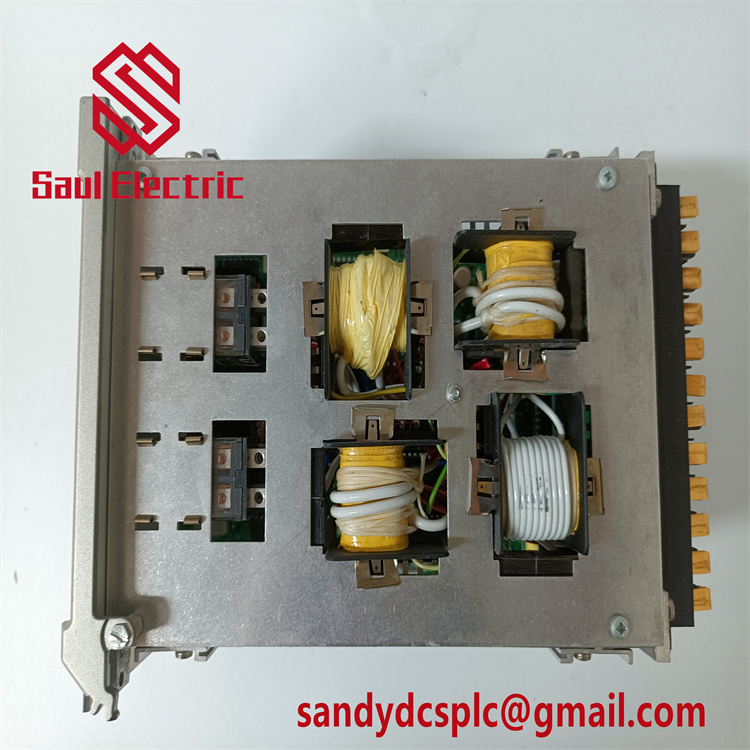

Featuring a microprocessor-based design, the ABB MR627 supports three-phase motors with rated currents up to 63 A and integrates 24V DC auxiliary power for reliable operation. It includes integrated voltage monitoring (380–690V AC) to detect phase loss, overvoltage, and undervoltage conditions, while its modular architecture allows for easy integration with other ABB S800 I/O modules, such as voltage units (VI15x) and digital expansion modules (DX1xx-FBP.0), enhancing system flexibility and scalability.

The ABB MR627 ensures reliable operation through multi-level protection functions, including overload, short circuit, and thermal protection. Its IP20-rated enclosure and EMI/RFI filtering protect against environmental contaminants and electromagnetic interference, making it suitable for harsh industrial environments. The module also supports Modbus RTU communication via an RS-485 interface, enabling seamless integration with distributed control systems (DCS) and SCADA platforms.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | MR627 P89627-0-2333400-300-401-601-701 |

| Manufacturer | ABB |

| Product Type | Motor Control Unit (S800 I/O Series) |

| Current Range | 2.0–63 A (three-phase) |

| Voltage Monitoring | 380–690V AC (via integrated voltage unit) |

| Auxiliary Power | 24V DC (19.2–30V DC) |

| Communication Interfaces | RS-485 (Modbus RTU) |

| Protection Functions | Overload, short circuit, phase loss, overvoltage, undervoltage |

| Operating Temperature | -20°C to +60°C |

| Physical Dimensions | 170.18 mm (width) x 115 mm (depth) x 73.66 mm (height) |

| Weight | 0.68 kg |

| Protection Level | IP20 (EN 60529) |

| Compliance | CE, UL, IECEx |

| Mounting Type | DIN rail |

| Redundancy Support | Dual power inputs |

| Data Logging | Stores up to 20 events with timestamps |

Key Features and Advantages

Comprehensive Motor Protection:

The ABB MR627 provides multi-level protection against overload, short circuit, and phase loss, ensuring motor longevity and minimizing downtime. Its true RMS current measurement and thermal modeling accurately monitor motor health, enabling predictive maintenance and reducing unplanned outages.

The ABB MR627 provides multi-level protection against overload, short circuit, and phase loss, ensuring motor longevity and minimizing downtime. Its true RMS current measurement and thermal modeling accurately monitor motor health, enabling predictive maintenance and reducing unplanned outages.

Flexible Communication:

With Modbus RTU support, the module integrates seamlessly with third-party systems, allowing real-time data exchange for remote monitoring and control. Optional expansion modules (e.g., EIU32.0 for Ethernet/IP) further enhance connectivity, enabling integration with modern industrial networks.

With Modbus RTU support, the module integrates seamlessly with third-party systems, allowing real-time data exchange for remote monitoring and control. Optional expansion modules (e.g., EIU32.0 for Ethernet/IP) further enhance connectivity, enabling integration with modern industrial networks.

Modular Design:

The S800 I/O platform supports scalable configurations, with the MR627 acting as the core controller. It can be paired with voltage units (VI15x) for power quality analysis and digital modules (DX1xx-FBP.0) for additional I/O channels, reducing cabling complexity and system costs.

The S800 I/O platform supports scalable configurations, with the MR627 acting as the core controller. It can be paired with voltage units (VI15x) for power quality analysis and digital modules (DX1xx-FBP.0) for additional I/O channels, reducing cabling complexity and system costs.

Easy Installation and Maintenance:

The DIN rail-mountable design and push-in terminals simplify installation, while LED status indicators and event logging facilitate quick diagnostics. The module’s hot-swap capability allows replacement without powering down the system, enhancing operational efficiency.

The DIN rail-mountable design and push-in terminals simplify installation, while LED status indicators and event logging facilitate quick diagnostics. The module’s hot-swap capability allows replacement without powering down the system, enhancing operational efficiency.

Compliance and Safety:

Certified to CE, UL, and IECEx standards, the ABB MR627 meets the highest safety requirements for hazardous environments, ensuring compliance with global industrial regulations.

Certified to CE, UL, and IECEx standards, the ABB MR627 meets the highest safety requirements for hazardous environments, ensuring compliance with global industrial regulations.

Application Areas

The ABB MR627 excels in demanding industrial environments across multiple sectors:

- Oil and Gas: Controls pumps and compressors in offshore platforms and refineries, ensuring reliable operation in harsh conditions.

- Power Generation: Manages motors in thermal and hydroelectric plants, optimizing energy efficiency and grid stability.

- Water Treatment: Regulates pumps and valves in filtration and distribution systems, ensuring compliance with environmental standards.

- Manufacturing: Drives conveyor systems, packaging machinery, and robotics in automotive and food processing facilities.

- Mining and Metals: Controls ore crushers and conveyor belts in remote, dusty environments, enhancing productivity and safety.

Its ability to handle high currents and support redundant configurations makes it ideal for applications requiring high reliability and scalability.

Related Products

- ABB VI15x Voltage Unit: Monitors three-phase voltages for advanced motor protection and power quality analysis.

- ABB DX1xx-FBP.0 Digital Module: Expands I/O capabilities with additional digital inputs/outputs and analog outputs.

- ABB EIU32.0 Ethernet/IP Adapter: Enables Ethernet communication for integration with modern industrial networks.

- ABB PDP32.0 PROFIBUS DP Module: Connects to PROFIBUS DP networks for seamless integration with PLCs and HMIs.

- ABB UMC100.3 Universal Motor Controller: Offers advanced motor management for single- and three-phase motors with Ethernet/IP support.

- ABB AC500 PLC Series: Scalable PLCs compatible with the S800 I/O platform for complex automation tasks.

- ABB CT4L/CT5L Current Transformers: Extends current measurement range for motors exceeding 63 A.

- ABB CEM11 Earth Leakage Sensor: Detects ground faults for enhanced safety in motor control systems.

- ABB CM10 ControlMaster: Universal process controller for advanced monitoring and control in industrial applications.

- ABB S800 I/O Modules: High-performance distributed I/O units for seamless integration with the MR627.

Installation and Maintenance

Installation Preparation:

Before installing the ABB MR627, ensure the DIN rail is securely grounded and properly aligned. Verify the power supply meets 24V DC requirements (19.2–30V DC) and inspect the module for physical damage. Use the slide-and-lock mechanism to attach the module to the rail, aligning the RS-485 connectors and power terminals. Configure the communication parameters (e.g., Modbus address) using the module’s dip switches and connect redundant cables if required.

Before installing the ABB MR627, ensure the DIN rail is securely grounded and properly aligned. Verify the power supply meets 24V DC requirements (19.2–30V DC) and inspect the module for physical damage. Use the slide-and-lock mechanism to attach the module to the rail, aligning the RS-485 connectors and power terminals. Configure the communication parameters (e.g., Modbus address) using the module’s dip switches and connect redundant cables if required.

Maintenance Recommendations:

Regularly check for loose connections and corrosion on the module’s terminals. Clean dust from the surface using a dry cloth, avoiding solvents. Monitor the LED status indicators for fault conditions; replace faulty modules immediately. For redundant systems, perform quarterly switchover tests to ensure failover functionality. Update firmware and control software regularly to leverage the latest features and security patches.

Regularly check for loose connections and corrosion on the module’s terminals. Clean dust from the surface using a dry cloth, avoiding solvents. Monitor the LED status indicators for fault conditions; replace faulty modules immediately. For redundant systems, perform quarterly switchover tests to ensure failover functionality. Update firmware and control software regularly to leverage the latest features and security patches.

Product Assurance

ABB guarantees the MR627 P89627-0-2333400-300-401-601-701 with a 1-year warranty, covering defects in materials and workmanship. The module undergoes rigorous testing to meet international standards, ensuring long-term reliability in industrial environments. Customers benefit from ABB’s global technical support network, offering 24/7 assistance for troubleshooting, firmware updates, and system optimization. With spot inventory and a 3-day delivery commitment, ABB ensures rapid deployment to minimize downtime. This combination of quality assurance, technical expertise, and responsive service makes the ABB MR627 a trusted choice for mission-critical motor control applications.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com