Description

Product Overview

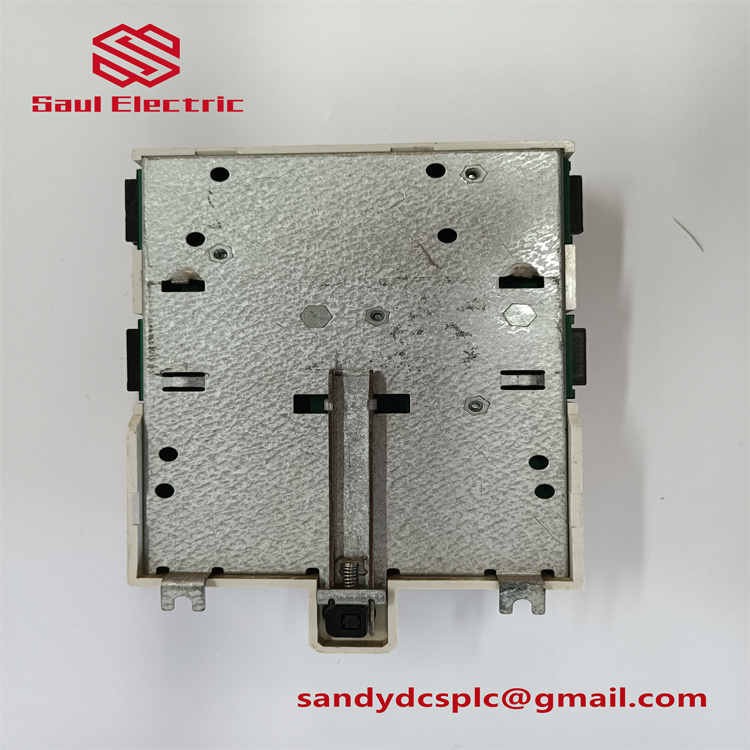

The ABB MB810 is a high-performance module mounting base designed for industrial automation systems, specifically engineered for the HPC800 platform within ABB’s S+SD series. As a critical component of distributed control systems (DCS), this baseplate provides a robust physical and electrical interface for installing HC800 and CP800 controllers, ensuring seamless integration and reliable operation in mission-critical applications.

Featuring a modular design, the ABB MB810 supports dual mounting positions (A for HC800, B for CP800) and accommodates redundant controller configurations, enhancing system availability. The baseplate includes integrated power distribution, communication interfaces, and diagnostic indicators, streamlining installation and maintenance. Its compact dimensions (243.84 mm x 73.66 mm x 170.18 mm) and lightweight construction (1.43 kg) make it suitable for space-constrained environments, while the IP20-rated enclosure protects against dust and solid particles.

The ABB MB810 ensures reliable connectivity through its CEX bus termination and Modula bus support, enabling high-speed data transfer between controllers and I/O modules. It also includes a real-time clock (RTC) with battery backup and addressable Ethernet ports, ensuring data integrity and system synchronization during power interruptions. This baseplate is compliant with international standards (CE, UL, IECEx), making it suitable for use in hazardous industrial environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | MB810 |

| Manufacturer | ABB |

| Product Type | Module Mounting Base (S+SD Series) |

| Compatible Modules | HC800, CP800 (with conformal coating) |

| Communication Interfaces | CEX bus, Modula bus, Ethernet (RJ45) |

| Power Supply | 24V DC (19.2–30V DC) |

| Operating Temperature | -20°C to +60°C |

| Physical Dimensions | 243.84 mm (depth) x 73.66 mm (height) x 170.18 mm (width) |

| Weight | 1.43 kg |

| Protection Level | IP20 (EN 60529) |

| Compliance | CE, UL, IECEx, RoHS |

| Mounting Type | DIN rail or panel-mounted |

| Redundancy Support | Dual controller configuration (A/B positions) |

| Backplane Support | Universal backplane for S+SD modules |

Key Features and Advantages

Modular Redundancy Design:

The ABB MB810 supports dual controller installations (HC800 and CP800), allowing for hot-swappable redundancy with minimal downtime. This design ensures continuous operation in critical processes such as oil refining, power generation, and chemical manufacturing.

The ABB MB810 supports dual controller installations (HC800 and CP800), allowing for hot-swappable redundancy with minimal downtime. This design ensures continuous operation in critical processes such as oil refining, power generation, and chemical manufacturing.

Reliable Connectivity:

With integrated CEX bus termination and Modula bus interfaces, the baseplate enables high-speed data transfer (up to 10 Mbps) between controllers and I/O modules. Redundant Ethernet ports and power inputs further enhance system resilience.

With integrated CEX bus termination and Modula bus interfaces, the baseplate enables high-speed data transfer (up to 10 Mbps) between controllers and I/O modules. Redundant Ethernet ports and power inputs further enhance system resilience.

Ease of Installation:

The slide-and-lock mechanism simplifies DIN rail mounting, while the addressable Ethernet ports eliminate the need for manual configuration. The baseplate also includes LED status indicators for quick diagnostics, reducing troubleshooting time.

The slide-and-lock mechanism simplifies DIN rail mounting, while the addressable Ethernet ports eliminate the need for manual configuration. The baseplate also includes LED status indicators for quick diagnostics, reducing troubleshooting time.

Environmental Robustness:

Rated for operation in extreme temperatures (-20°C to +60°C) and protected by an IP20 enclosure, the ABB MB810 withstands harsh industrial conditions, including dust, vibration, and electromagnetic interference.

Rated for operation in extreme temperatures (-20°C to +60°C) and protected by an IP20 enclosure, the ABB MB810 withstands harsh industrial conditions, including dust, vibration, and electromagnetic interference.

Compliance and Safety:

Certified to CE, UL, and IECEx standards, this baseplate meets the highest safety requirements for hazardous environments, ensuring compliance with global industrial regulations.

Certified to CE, UL, and IECEx standards, this baseplate meets the highest safety requirements for hazardous environments, ensuring compliance with global industrial regulations.

Application Areas

The ABB MB810 is widely used in industrial automation systems across multiple sectors:

- Oil and Gas: Supports redundant controller configurations in offshore platforms and refineries for real-time process monitoring and safety-critical operations.

- Power Generation: Enables high-availability control systems in thermal, hydroelectric, and renewable energy plants, ensuring grid stability and efficiency.

- Chemical and Pharmaceutical: Provides reliable mounting for controllers in batch processing and quality control systems, adhering to strict regulatory standards.

- Water Treatment: Manages complex filtration and distribution systems, ensuring compliance with environmental regulations.

- Mining and Metals: Facilitates robust control of conveyor systems and ore processing equipment in harsh, remote locations.

Its ability to support dual controllers and withstand extreme conditions makes it ideal for applications requiring high reliability and scalability.

Related Products

- HC800 Controller: High-performance process controller compatible with the MB810 baseplate, designed for advanced control applications.

- CP800 Controller: Compact controller with conformal coating for harsh environments, mounted on the MB810 baseplate.

- CTB810/CTB811 Terminal Blocks: Used to terminate CEX bus connections on the MB810 baseplate for extended I/O configurations.

- S+SD I/O Modules: High-performance distributed I/O units compatible with the MB810 baseplate and HPC800 platform.

- TB850 CEX Bus Terminator: Expands modular system capabilities by adding additional I/O clusters.

- SB821 External Battery Unit: Provides extended memory backup for redundant controller configurations.

- HPC800K01/K02 Controllers: Upgraded versions of HC800 with enhanced processing power and memory.

- ABB PM856K01: Entry-level controller for small-scale automation projects, compatible with S+SD systems.

- ABB CI854K01: PROFIBUS DP/V1 communication module for connecting remote I/O devices.

- ABB TB807 Module Bus Terminator: Configures I/O clusters for optimized system performance.

Installation and Maintenance

Installation Preparation:

Before installing the ABB MB810, ensure the DIN rail is securely grounded and properly aligned. Verify the power supply meets 24V DC requirements (19.2–30V DC) and inspect the baseplate for physical damage. Use the slide-and-lock mechanism to attach the baseplate to the rail, aligning the CEX bus connectors and power terminals. Configure the Ethernet addresses using the labels on the baseplate and connect redundant cables if required.

Before installing the ABB MB810, ensure the DIN rail is securely grounded and properly aligned. Verify the power supply meets 24V DC requirements (19.2–30V DC) and inspect the baseplate for physical damage. Use the slide-and-lock mechanism to attach the baseplate to the rail, aligning the CEX bus connectors and power terminals. Configure the Ethernet addresses using the labels on the baseplate and connect redundant cables if required.

Maintenance Recommendations:

Regularly check for loose connections and corrosion on the baseplate’s terminals. Clean dust from the surface using a dry cloth, avoiding solvents. Monitor the battery status LED; replace the internal lithium battery every 5 years or as indicated by diagnostics. For redundant systems, perform quarterly switchover tests to ensure failover functionality. Update firmware and control software regularly to leverage the latest features and security patches.

Regularly check for loose connections and corrosion on the baseplate’s terminals. Clean dust from the surface using a dry cloth, avoiding solvents. Monitor the battery status LED; replace the internal lithium battery every 5 years or as indicated by diagnostics. For redundant systems, perform quarterly switchover tests to ensure failover functionality. Update firmware and control software regularly to leverage the latest features and security patches.

Product Assurance

ABB guarantees the MB810 with a 1-year warranty, covering defects in materials and workmanship. The baseplate undergoes rigorous testing to meet international standards, ensuring long-term reliability in industrial environments. Customers benefit from ABB’s global technical support network, offering 24/7 assistance for troubleshooting, firmware updates, and system optimization. With spot inventory and a 3-day delivery commitment, ABB ensures rapid deployment to minimize downtime. This combination of quality assurance, technical expertise, and responsive service makes the ABB MB810 a trusted choice for mission-critical automation systems.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com