Description

Product Overview

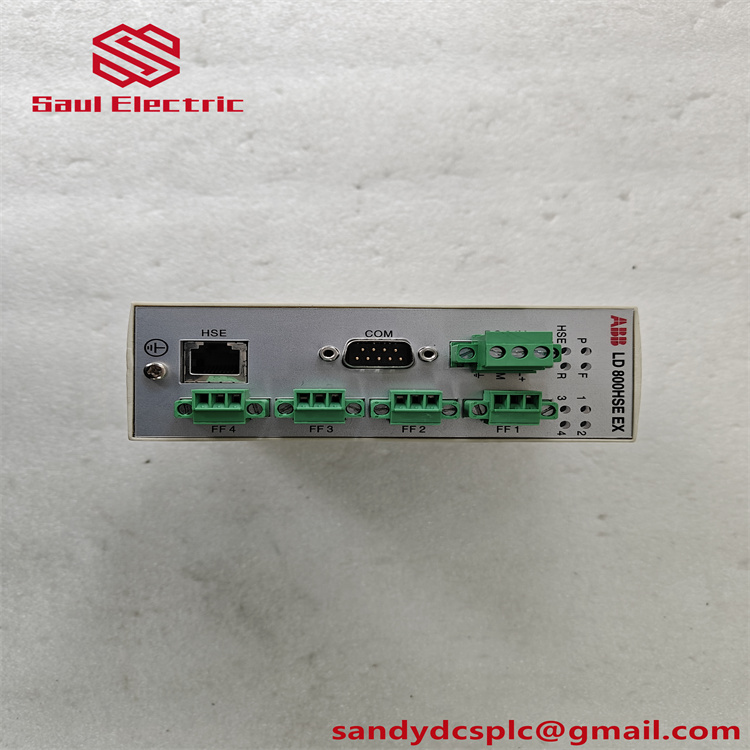

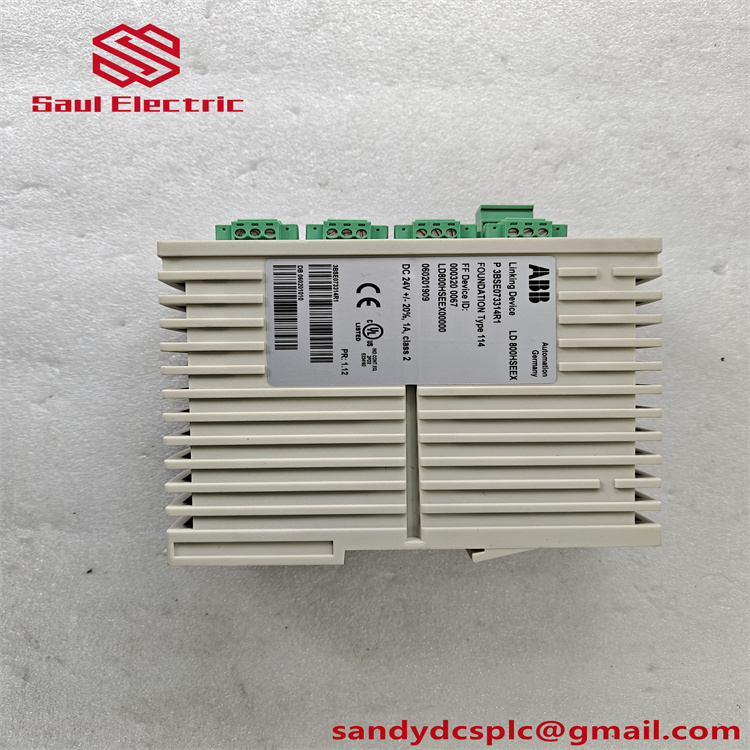

The ABB LD800HSEEX 3BSE073314R1 is a high-performance FOUNDATION Fieldbus Linking Device engineered to bridge High-Speed Ethernet (HSE) and H1 fieldbus networks in industrial automation systems. As part of ABB’s Industrial Digitalization portfolio, this module enables seamless integration of field devices—such as sensors, actuators, and controllers—into supervisory control systems, ensuring real-time data exchange and reliable process management. Certified for ATEX Zone 2 and IECEx Zone 2 hazardous environments , the LD800HSEEX 3BSE073314R1 is ideal for oil & gas platforms, chemical plants, and other facilities where safety and explosion protection are critical.

With support for four H1 links and one HSE connector, the LD800HSEEX 3BSE073314R1 acts as a compact gateway, allowing transparent access to field device parameters, diagnostics, and control functions via ABB’s Ability™ 800xA DCS or third-party systems . Its Class 42C HSE Profile compliance ensures compatibility with advanced automation architectures, while dual-port Ethernet connectivity supports redundant network configurations for mission-critical applications. The module’s DIN rail-mountable design (47 x 131 x 111 mm) and IP20 protection make it suitable for both centralized control rooms and decentralized field installations, reducing cabling costs by up to 80% compared to traditional solutions .

Key functionalities include H1-to-HSE data republishing, alarm distribution, and time synchronization via SNTP, ensuring seamless integration with ABB’s predictive maintenance tools. By combining Galvanic isolation for H1 channels and G3 coating for corrosion resistance , the LD800HSEEX 3BSE073314R1 delivers robust performance in harsh industrial environments, meeting ANSI/ISA 71.04 and EN 60068-2-60 standards for environmental resilience.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB LD800HSEEX 3BSE073314R1 |

| Manufacturer | ABB |

| Product Type | FOUNDATION Fieldbus Linking Device |

| Communication Protocols | FF HSE, FF H1 (31.25 kbit/s), RS-232 |

| HSE Interface | 1 x 10/100 Mbit/s Ethernet (Auto-sensing) |

| H1 Channels | 4 x FF H1 (3-pole screw terminals, galvanically isolated) |

| Power Supply | 24 VDC (±20%), 200 mA typical consumption |

| Redundancy Support | Redundant HSE and H1 configurations |

| Certifications | ATEX II 3G Ex nA IIC T4 Gc, IECEx Ex nA IIC T4 Gc, cULus Class I Div 2 Groups A/B/C/D |

| Operating Temperature | 0°C to +55°C (non-vertical mounting may reduce upper limit) |

| Physical Dimensions | 47 x 131 x 111 mm (DIN rail mountable) |

| Weight | 0.4 kg |

| Environmental Protection | IP20, G3 coating for corrosion resistance |

Key Features and Advantages

Hazardous Area Certification: The LD800HSEEX 3BSE073314R1 is certified for ATEX Zone 2 and IECEx Zone 2, allowing direct installation in explosive gas environments without additional enclosure, reducing infrastructure costs and complexity .

High-Speed Data Integration: By acting as a Link Active Scheduler (LAS) for each H1 channel, the module ensures deterministic communication between field devices and the control system, supporting up to 4 sub-cycles for time-critical processes like valve control and batch manufacturing .

Redundancy Capabilities: Dual-port Ethernet and redundant H1 links enable seamless failover, ensuring continuous operation in systems where downtime is intolerable. A dedicated redundancy link cable (sold separately) synchronizes primary and secondary devices for rapid switchover .

Comprehensive Diagnostics: Built-in web server diagnostics provide real-time insights into H1 link health, device status, and communication errors. This allows proactive maintenance and reduces mean time to repair (MTTR) in complex process networks .

Flexible Configuration: The module supports transparent device configuration via ABB’s Field Device Manager (FDM) or third-party tools, eliminating the need for proprietary software. Its hot-swap capability enables module replacement without disrupting ongoing operations .

Applications

The LD800HSEEX 3BSE073314R1 excels in industries requiring reliable fieldbus integration in hazardous or harsh environments:

- Oil & Gas: Connects H1 field devices (e.g., flow meters, pressure transmitters) to HSE networks in offshore platforms and refineries, ensuring compliance with strict safety standards .

- Chemical Processing: Enables real-time monitoring of reactors and distillation columns in Zone 2 environments, supporting predictive maintenance to avoid process deviations .

- Power Generation: Integrates H1-based turbine control systems with HSE for centralized monitoring in power plants, enhancing operational efficiency and grid stability .

- Pharmaceuticals: Manages cleanroom HVAC systems and critical process equipment via redundant H1 links, ensuring sterile environments and regulatory compliance .

- Water Treatment: Facilitates remote diagnostics and control of pumps and blowers in wastewater treatment plants, optimizing energy consumption and reducing manual intervention .

Related Products

- ABB LD800HSE: Non-explosion-proof version for safe areas, offering identical functionality without hazardous environment certifications.

- ABB LD810HSEEX: 8-channel H1 linking device for large-scale systems requiring higher connectivity, certified for Zone 2.

- ABB CI860 HSE Interface Module: Integrates HSE networks with ABB’s AC 800M PLC, enabling seamless integration with IEC 61131-3 controllers .

- ABB FDM (Field Device Manager): Software tool for configuring and maintaining LD800HSEEX 3BSE073314R1 and connected field devices.

- ABB Redundancy Link Cable: Required for redundant configurations, ensuring synchronization between primary and secondary linking devices.

Installation and Maintenance

Installation Preparation:

- Verify compliance with ATEX/IECEx installation guidelines, including proper grounding and cable routing in hazardous areas.

- Mount the LD800HSEEX 3BSE073314R1 on a 35 mm DIN rail in a location with adequate ventilation (IP20 protection requires dust-free environments).

- Connect H1 links using shielded twisted-pair cables (max. 1,900 m per segment) and terminate with 100 Ω resistors at both ends .

Maintenance Recommendations:

- Regularly check the module’s status LEDs for H1 link health and communication errors.

- Perform firmware updates via ABB’s Field Device Manager to access new features and security patches.

- Inspect physical connections and clean dust from the module’s vents every 6 months to maintain thermal performance.

- Replace the module if it fails self-tests or exhibits persistent communication issues, ensuring compatibility with ABB’s 3BSE073314R1 replacement policy .

Product Warranty and Support

ABB guarantees the LD800HSEEX 3BSE073314R1 against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers repair or replacement of faulty components, excluding damage caused by improper installation or voltage surges.

Customers benefit from ABB’s global technical support network, including 24/7 remote diagnostics and on-site assistance for complex installations. ABB also offers extended warranty plans and training programs to help users maximize the module’s capabilities in advanced automation scenarios.

Product Information

- Brand Model: ABB LD800HSEEX 3BSE073314R1

- Product Name: FOUNDATION Fieldbus Linking Device

- Warranty: 1 year

- Size: 47 x 131 x 111 mm

- Weight: 0.4 kg

- Origin: Sweden

- Inventory: Spot/Futures

- Delivery Time: Goods in stock will be dispatched within 3 days after payment

- Order Time: Goods will be dispatched within one month after payment

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com