Description

. Many products are not yet available. Please contact us to learn more about them

. In case of any inconsistency between the product model and the displayed picture, the model shall prevail. For specific product pictures, please contact us and we will take photos of the goods for confirmation

. We share multiple warehouses around the world, so please understand that it may take several hours to accurately return it to you. Of course, we will respond to your concerns as soon as possible

Product Overview

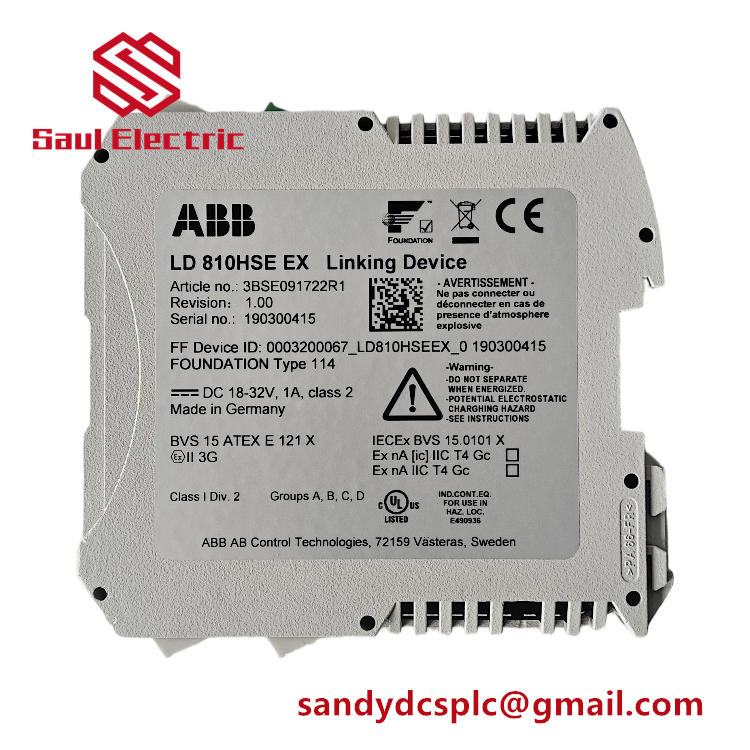

The ABB LD 810HSE EX 3BSE091722R1 is an explosion-proof (EX-rated) Highway Addressable Remote Transducer (HART) Safety Extra (HSE) communication module, specifically engineered for seamless integration into ABB’s AC 800M and 800xA distributed control systems (DCS). Designed to operate in hazardous industrial environments where explosive atmospheres (gas or dust) may be present, ABB LD 810HSE EX 3BSE091722R1 acts as a critical bridge between field devices (e.g., pressure sensors, flow meters, actuators) in high-risk areas and the central control system, enabling reliable, real-time data transmission without compromising safety.

As a core component of ABB’s process automation portfolio for hazardous locations, ABB LD 810HSE EX 3BSE091722R1 complies with global explosion-protection standards (ATEX, IECEx) and maintains robust communication via the HSE protocol—ensuring compatibility with both ABB and third-party HART-enabled devices. Its rugged design and ability to withstand extreme temperatures, vibration, and chemical exposure make ABB LD 810HSE EX 3BSE091722R1 an indispensable solution for industries where operational safety and system uptime are non-negotiable, such as oil & gas, chemical, and petrochemical processing.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB LD 810HSE EX 3BSE091722R1 |

| Manufacturer | ABB |

| Product Type | Explosion-Proof HSE Communication Module |

| Explosion Protection Certifications | ATEX Zone 1 (Gas), ATEX Zone 21 (Dust); IECEx Zone 1 (Gas), IECEx Zone 21 (Dust) |

| Supported Communication Protocol | HART Safety Extra (HSE), Modbus RTU (secondary) |

| Power Supply | 24 V DC (from AC 800M backplane), 0.8 A Typical Current |

| Operating Temperature | -40°C to 60°C (-40°F to 140°F) |

| Enclosure Rating | IP66 (Ingress Protection); Flameproof Enclosure (Ex d) |

| Backplane Compatibility | ABB AC 800M Backplane (e.g., BC810, BC820) |

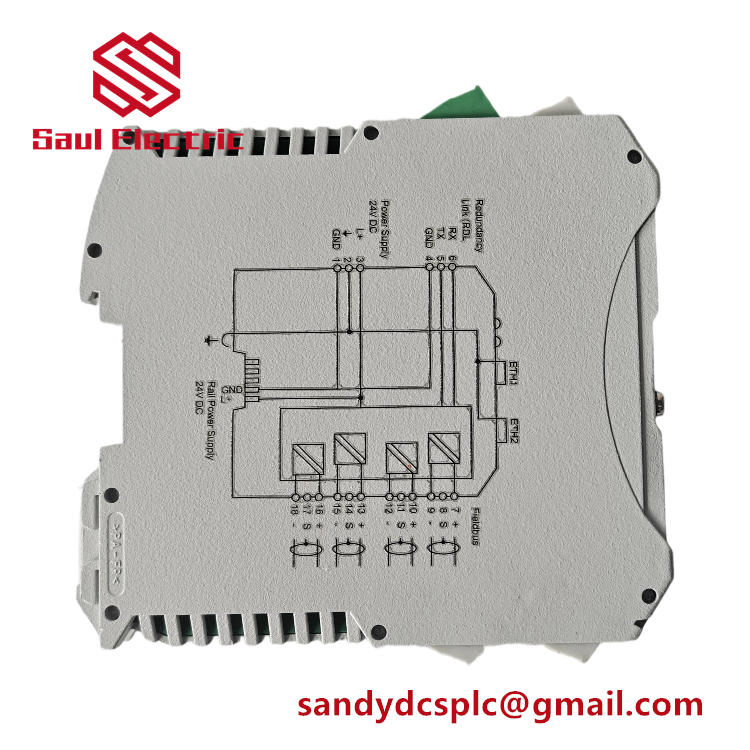

| Communication Ports | 2 x HSE Ethernet (10/100 Mbps, RJ45, EX-rated); 1 x RS485 (for Modbus RTU) |

| Programming/Configuration Software | ABB Control Builder M (for AC 800M), ABB 800xA Engineering Studio |

| Dimensions (W x H x D) | 55 mm x 120 mm x 180 mm (2.17 in x 4.72 in x 7.09 in) |

| Weight | Approximately 1.2 kg (2.65 lbs) |

| Vibration Resistance | 5-150 Hz, 10 m/s² (IEC 60068-2-6) |

| Chemical Compatibility | Resistant to common industrial chemicals (e.g., hydrocarbons, solvents) |

Main Features and Advantages

Explosion-Proof Design for Hazardous Areas: ABB LD 810HSE EX 3BSE091722R1 features a flameproof (Ex d) enclosure and meets strict ATEX/IECEx certifications for Zone 1 (gas) and Zone 21 (dust) environments. This design eliminates the risk of the module becoming an ignition source, even in atmospheres with flammable gases (e.g., methane, propane) or combustible dust (e.g., coal, plastic particles)—a critical advantage over non-EX communication modules, which cannot be safely deployed in these high-risk areas.

Reliable HSE Protocol Support: Unlike basic communication modules, ABB LD 810HSE EX 3BSE091722R1 leverages the HSE protocol, a safety-enhanced version of HART that prioritizes real-time data transmission for process control and safety shutdown systems. HSE enables simultaneous transfer of process data (e.g., pressure readings) and diagnostic information (e.g., sensor drift alerts), allowing operators to monitor both device performance and process conditions—reducing the risk of unplanned downtime and improving maintenance efficiency.

Seamless Integration with ABB Ecosystems: ABB LD 810HSE EX 3BSE091722R1 is fully compatible with ABB’s AC 800M PLC and 800xA DCS, eliminating integration challenges common with third-party EX modules. It works seamlessly with ABB’s Control Builder M software for configuration, enabling engineers to set up communication parameters, map field devices, and implement safety logic without specialized coding. This compatibility also extends to ABB’s safety modules (e.g., SM 810) and HMI panels, creating a unified control ecosystem for hazardous processes.

Robust Environmental Durability: Engineered to withstand harsh industrial conditions, ABB LD 810HSE EX 3BSE091722R1 operates in temperatures ranging from -40°C to 60°C and resists vibration (up to 10 m/s²) and chemical exposure. Its IP66 enclosure prevents dust and water ingress, while corrosion-resistant materials protect internal components from harsh media (e.g., saltwater in offshore oil applications). This durability ensures consistent performance in environments where standard modules would fail, extending the module’s operational lifespan and lowering total cost of ownership.

Application Fields

ABB LD 810HSE EX 3BSE091722R1 is a cornerstone technology in the upstream oil & gas industry, where it is deployed in wellhead monitoring, offshore platforms, and gas processing facilities. In wellhead operations, it connects pressure and temperature sensors in Zone 1 hazardous areas to the central AC 800M PLC, enabling real-time monitoring of well pressure and flow rates—critical for preventing blowouts or equipment failure. On offshore platforms, its resistance to saltwater corrosion and extreme temperatures ensures reliable communication between subsea actuators and the 800xA DCS, even in harsh marine environments.

In the chemical and petrochemical sectors, ABB LD 810HSE EX 3BSE091722R1 is used in reactor control, solvent storage, and distillation processes—areas where flammable solvents (e.g., ethanol, benzene) create explosive atmospheres. It facilitates data transmission between HART-enabled level sensors in Zone 21 dust-prone areas (e.g., plastic pellet storage) and the control system, ensuring accurate inventory tracking and preventing overfilling, which could lead to spills or ignition risks. Its HSE protocol support also enables integration with safety shutdown systems, allowing for automatic valve closure if process variables exceed safe limits.

The module also finds applications in the pharmaceutical industry, specifically in facilities handling flammable active pharmaceutical ingredients (APIs) or solvent-based manufacturing processes. ABB LD 810HSE EX 3BSE091722R1 connects hygienic sensors (e.g., pressure transmitters for tablet presses) in Zone 1 areas to the 800xA DCS, ensuring compliance with GMP (Good Manufacturing Practices) while maintaining explosion safety. Its easy configuration via Control Builder M simplifies system updates, a key requirement in pharmaceutical manufacturing where process changes are common.

Additionally, ABB LD 810HSE EX 3BSE091722R1 is used in mining operations, particularly in coal processing plants where combustible coal dust creates Zone 21 environments. It connects dust concentration sensors and conveyor belt actuators to the control system, enabling real-time monitoring of dust levels and automated shutdowns if concentrations exceed explosive thresholds—protecting workers and equipment from dust explosions.

Related Products

ABB PPD513 | AC800PEC | excitation controller | PP D513

PPD513A25-111615 3BHE039724R2565

ABB IGCT 5SHY4045L0006 3BHB030310R0001 Module

ABB PPD539A102 3BHE039770R0102

HS:8538 9000.00

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com