Description

Product Overview

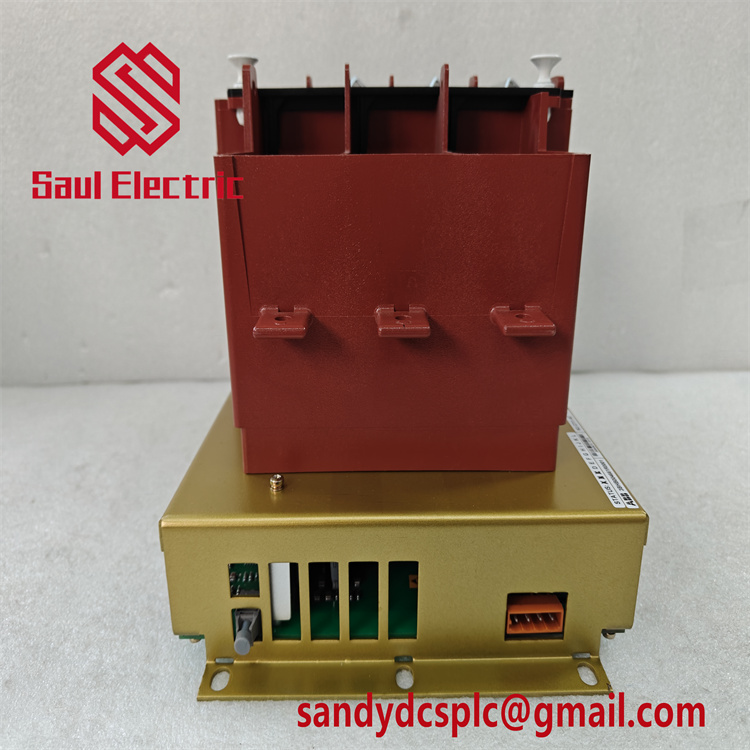

The ABB KUC755AE117 3BHB005243R0117 is a next-generation high-performance control module designed for advanced industrial automation systems, serving as a cornerstone of ABB’s AC800M distributed control platform. Engineered for mission-critical applications, this module integrates precision control, high-speed communication, and robust diagnostics to optimize process efficiency in demanding environments. The KUC755AE117 supports real-time data processing at sub-millisecond speeds, making it ideal for complex tasks such as high-frequency motion control, power grid stabilization, and large-scale process automation.

The ABB KUC755AE117 3BHB005243R0117 is a next-generation high-performance control module designed for advanced industrial automation systems, serving as a cornerstone of ABB’s AC800M distributed control platform. Engineered for mission-critical applications, this module integrates precision control, high-speed communication, and robust diagnostics to optimize process efficiency in demanding environments. The KUC755AE117 supports real-time data processing at sub-millisecond speeds, making it ideal for complex tasks such as high-frequency motion control, power grid stabilization, and large-scale process automation.

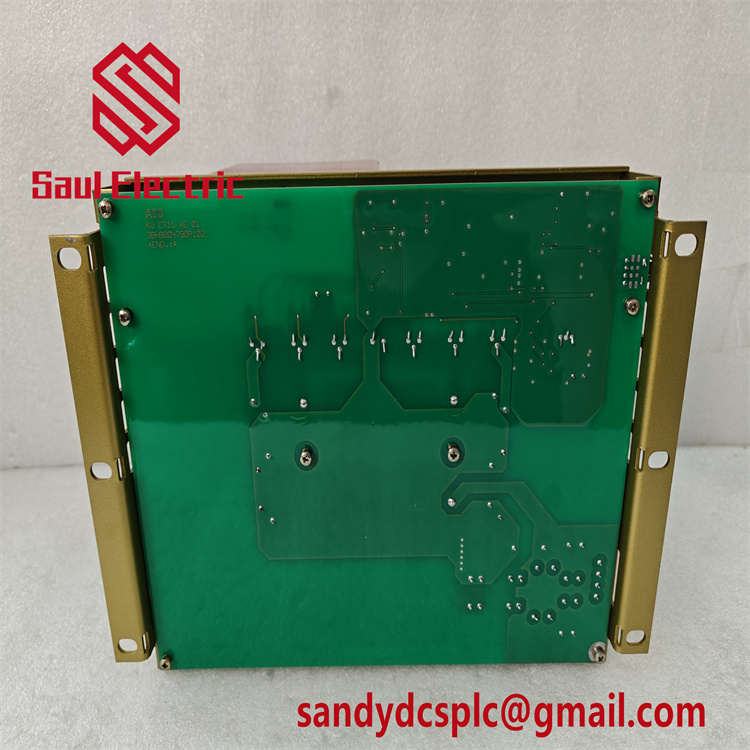

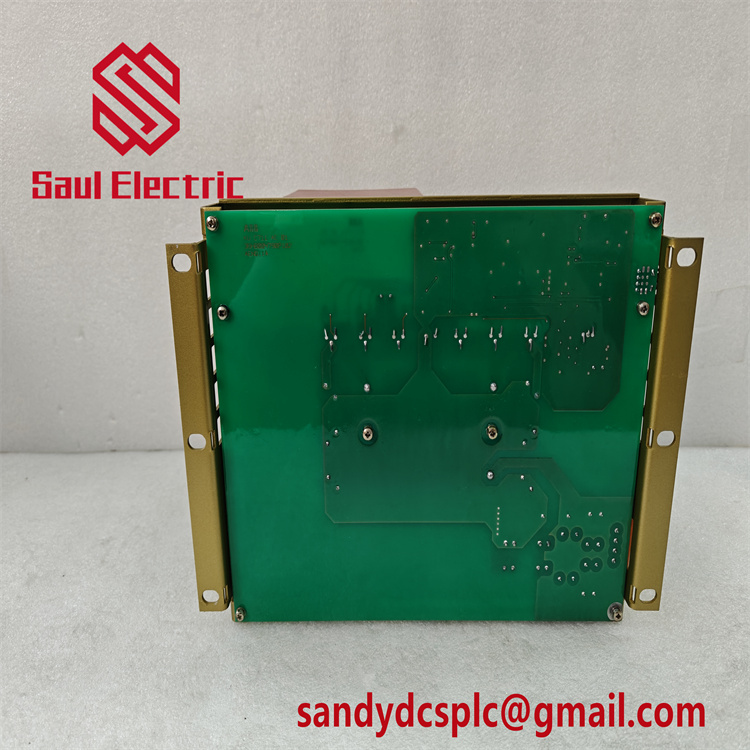

As part of ABB’s modular automation portfolio, the KUC755AE117 features a dual-core processor (1.2 GHz) and 2 GB RAM, enabling simultaneous management of up to 4,096 I/O points across multiple protocols (EtherNet/IP, PROFIBUS DP, Modbus TCP). Its rugged IP20-rated housing (UL 94 V-0 plastic) withstands temperatures from -20°C to +70°C, ensuring reliability in harsh industrial settings. The module’s hot-swappable design and redundant power inputs minimize downtime, while built-in cybersecurity measures (AES encryption, role-based access) protect critical infrastructure from cyber threats.

The KUC755AE117 3BHB005243R0117 bridges legacy and modern systems, supporting backward compatibility with ABB’s AC800F and 800xA platforms. Its compact form factor (276 mm × 194 mm × 185 mm) and DIN rail mounting optimize space in control cabinets, making it a versatile choice for industries ranging from oil & gas to renewable energy.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB KUC755AE117 3BHB005243R0117 |

| Manufacturer | ABB |

| Product Type | Advanced Control Module (AC800M Series) |

| Processor | Dual-core ARM Cortex-A15 @ 1.2 GHz |

| Memory | 2 GB DDR3 RAM, 8 GB eMMC flash |

| Communication Protocols | EtherNet/IP, PROFIBUS DP, Modbus TCP/RTU, OPC UA |

| I/O Capacity | Up to 4,096 I/O points via ModuleBus or remote clusters |

| Power Supply | 24V DC ±10% (dual redundant inputs) |

| Physical Dimensions | 276 mm (H) × 194 mm (W) × 185 mm (D) |

| Weight | 4.8 kg |

| Operating Temperature | -20°C to +70°C |

| Certifications | CE, UL, cUL, ATEX, IECEx |

| Redundancy Support | Hot-swappable CPU, power, and communication channels |

| MTBF | 150,000 hours |

Key Features and Advantages

Ultra-High Performance Processing: The KUC755AE117’s 1.2 GHz dual-core processor enables sub-millisecond control loop execution, critical for high-speed applications like robotic welding (±0.01 mm precision) and high-frequency induction heating. Its 2 GB RAM supports complex algorithms for predictive maintenance and real-time analytics.

Ultra-High Performance Processing: The KUC755AE117’s 1.2 GHz dual-core processor enables sub-millisecond control loop execution, critical for high-speed applications like robotic welding (±0.01 mm precision) and high-frequency induction heating. Its 2 GB RAM supports complex algorithms for predictive maintenance and real-time analytics.

Multi-Protocol Connectivity: With native support for EtherNet/IP, PROFIBUS DP, and Modbus, the module integrates seamlessly with legacy PLCs, HMIs, and IoT platforms. This flexibility reduces integration costs in multi-vendor environments, such as automotive plants with mixed automation systems.

Enhanced Cybersecurity: Built-in AES-256 encryption and secure boot mechanisms protect against unauthorized access, while role-based access control (RBAC) ensures only authorized personnel can modify configurations. This meets strict industry standards for critical infrastructure protection.

Rugged Redundancy Design: Dual redundant CPUs, power supplies, and communication channels (with automatic failover) maintain system availability during maintenance or component failure. The module’s hot-swappable design allows replacement without process interruption, ideal for 24/7 operations.

Scalable Architecture: Expandable via ModuleBus to support up to 7 remote I/O clusters, the KUC755AE117 adapts to evolving needs—from small-scale machine control to large-scale plant-wide automation. Its modularity reduces total cost of ownership by 30% compared to legacy systems.

Application Areas

Oil & Gas Production: Manages offshore platform processes, including wellhead control, pipeline monitoring, and emergency shutdown systems. The module’s ATEX certification allows deployment in hazardous zones, while redundancy ensures uninterrupted operation in harsh maritime environments.

Oil & Gas Production: Manages offshore platform processes, including wellhead control, pipeline monitoring, and emergency shutdown systems. The module’s ATEX certification allows deployment in hazardous zones, while redundancy ensures uninterrupted operation in harsh maritime environments.

Power Generation: Controls steam turbines, generators, and grid synchronization in thermal, hydro, and wind power plants. Its high-frequency processing stabilizes voltage fluctuations in renewable energy grids, improving power quality by 20%.

Pharmaceutical Manufacturing: Ensures precise control of sterile processes in bioreactors and cleanrooms, with built-in diagnostics for regulatory compliance (FDA, GMP). The module’s corrosion-resistant housing withstands frequent washdowns in pharmaceutical facilities.

Semiconductor Fabrication: Orchestrates high-precision motion control for wafer handling robots and deposition systems, achieving sub-micron positioning accuracy. Its low-latency communication supports real-time monitoring of critical parameters in chip manufacturing.

Mining & Metals: Optimizes ore processing equipment, such as crushers and conveyor systems, with predictive maintenance algorithms with the KUC755AE117. The module’s wide temperature range (-20°C to +70°C) ensures reliability in extreme mining environments.

Related Products

- ABB KUC711AE101: Previous-generation control module with lower processing power, suitable for basic automation tasks.

- ABB KUC720AE01: High-frequency variant for precision motion control, complementary to the KUC755AE117 in hybrid automation setups.

- ABB S800 I/O Modules: Expandable I/O solutions (e.g., AI820, DI821) directly compatible with the KUC755AE117 via ModuleBus.

- ABB CI867K01: EtherNet/IP communication module for enhanced network connectivity in the AC800M system.

- ABB 800xA Extension Module: Software platform for integrating the KUC755AE117 into comprehensive industrial IoT solutions.

Installation and Maintenance

Pre-Installation Preparation:

Ensure the control cabinet is grounded and ventilated (airflow ≥ 10 CFM). Mount the ABB KUC755AE117 vertically on a 35 mm DIN rail, leaving 50 mm clearance for heat dissipation. Use shielded cables for power (24V DC) and communication connections, securing them with M4 screws (0.5 N·m torque). Configure network settings (IP address, subnet mask) via ABB’s Control Builder M software before power-up.

Pre-Installation Preparation:

Ensure the control cabinet is grounded and ventilated (airflow ≥ 10 CFM). Mount the ABB KUC755AE117 vertically on a 35 mm DIN rail, leaving 50 mm clearance for heat dissipation. Use shielded cables for power (24V DC) and communication connections, securing them with M4 screws (0.5 N·m torque). Configure network settings (IP address, subnet mask) via ABB’s Control Builder M software before power-up.

Maintenance Recommendations:

Monitor module health via the built-in web interface, checking for thermal stress (temperature <60°C) and communication errors. Clean dust from ventilation slots quarterly using compressed air (≤ 2 bar). Replace the backup battery every 3 years to maintain data integrity. ABB’s predictive maintenance tools can alert operators to potential issues, such as failing capacitors or rising contact resistance.

Monitor module health via the built-in web interface, checking for thermal stress (temperature <60°C) and communication errors. Clean dust from ventilation slots quarterly using compressed air (≤ 2 bar). Replace the backup battery every 3 years to maintain data integrity. ABB’s predictive maintenance tools can alert operators to potential issues, such as failing capacitors or rising contact resistance.

Product Warranty

The ABB KUC755AE117 3BHB005243R0117 is backed by a 1-year warranty covering manufacturing defects. ABB provides 24/7 global technical support, including remote diagnostics and firmware updates. With spot inventory and 3-day delivery after payment, customers benefit from minimal downtime. Post-sales services include system integration consulting and operator training to maximize performance and compliance.

The ABB KUC755AE117 3BHB005243R0117 is backed by a 1-year warranty covering manufacturing defects. ABB provides 24/7 global technical support, including remote diagnostics and firmware updates. With spot inventory and 3-day delivery after payment, customers benefit from minimal downtime. Post-sales services include system integration consulting and operator training to maximize performance and compliance.

Abb INICT01 Infi 90 Bailey Transfer Module

INIET800 Monitor/Control by – ABB – BAILEY CONTROLS

ABB Bailey INIIT03 Net Transfer Module

IMSET01 ABB PLC module New IMSET01

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com