Description

Product Overview

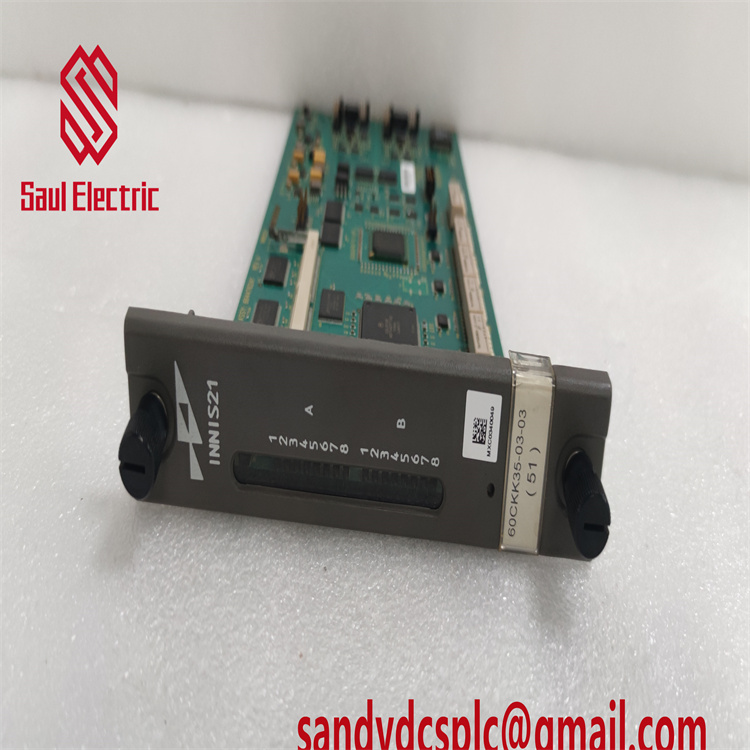

The ABB INSUMMCU2 MCU2A02V24 is a high-performance Intelligent Motor Control Unit (IMC) designed for precise control and protection of small to medium AC motors in industrial automation systems. As part of ABB’s INSUM motor management family, this module integrates advanced monitoring, diagnostics, and communication capabilities to optimize motor performance while minimizing downtime. The INSUMMCU2 MCU2A02V24 supports a wide voltage range (208–240V AC) and features a compact DIN rail-mountable design, making it ideal for applications requiring space-efficient and reliable motor control solutions.

The ABB INSUMMCU2 MCU2A02V24 is a high-performance Intelligent Motor Control Unit (IMC) designed for precise control and protection of small to medium AC motors in industrial automation systems. As part of ABB’s INSUM motor management family, this module integrates advanced monitoring, diagnostics, and communication capabilities to optimize motor performance while minimizing downtime. The INSUMMCU2 MCU2A02V24 supports a wide voltage range (208–240V AC) and features a compact DIN rail-mountable design, making it ideal for applications requiring space-efficient and reliable motor control solutions.

Engineered with a microprocessor-based architecture, the INSUMMCU2 MCU2A02V24 offers comprehensive motor protection against overload, short circuit, phase failure, and voltage fluctuations. Its modular design allows seamless integration with ABB’s INSUM backplane systems, enabling real-time data exchange via LON bus or Modbus RTU protocols. The module supports both open-loop and closed-loop control modes, adapting to diverse industrial requirements such as conveyor systems, pumps, and HVAC applications. With built-in event logging and diagnostic tools, the INSUMMCU2 MCU2A02V24 provides actionable insights into motor health, reducing maintenance complexity and extending equipment lifespan.

The INSUMMCU2 MCU2A02V24 is certified for hazardous environments (ATEX/IECEx) and operates reliably across a wide temperature range (-25°C to +70°C), ensuring resilience in harsh industrial settings. Its compatibility with ABB’s System 800xA and Symphony Plus platforms enhances system interoperability, enabling centralized monitoring and control in large-scale process automation scenarios.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | INSUMMCU2 MCU2A02V24 |

| Manufacturer | ABB |

| Product Type | Intelligent Motor Control Unit (IMC) |

| Voltage Range | 208–240V AC (main supply), 24V DC (auxiliary power) |

| Current Rating | 10A (continuous), 63A (peak) |

| Control Modes | Open-loop, closed-loop |

| Communication Protocols | LON bus, Modbus RTU, PROFIBUS DP (optional via gateway) |

| Protection Functions | Overload, short circuit, phase failure, undervoltage/overvoltage |

| Physical Dimensions | 105 mm (H) × 25 mm (W) × 175 mm (D) |

| Weight | 0.68 kg |

| Operating Temperature | -25°C to +70°C |

| Certifications | CE, UL, cUL, ATEX (Zone 2), IECEx |

| Mounting | 35 mm DIN rail |

| Data Logging | Stores up to 20 events/alerts with timestamps |

Key Features and Advantages

Comprehensive Motor Protection: The INSUMMCU2 MCU2A02V24 safeguards motors from critical faults (e.g., phase imbalance, thermal overload) through advanced algorithms and real-time monitoring. Its voltage unit continuously tracks input voltage, ensuring stable operation even in fluctuating power environments.

Comprehensive Motor Protection: The INSUMMCU2 MCU2A02V24 safeguards motors from critical faults (e.g., phase imbalance, thermal overload) through advanced algorithms and real-time monitoring. Its voltage unit continuously tracks input voltage, ensuring stable operation even in fluctuating power environments.

Flexible Control Architecture: Supports both open-loop (direct start/stop) and closed-loop (PID-based speed/torque control) modes, accommodating diverse industrial applications. The module’s configurable I/O channels enable integration with sensors, actuators, and HMIs for seamless process automation.

Rugged Industrial Design: Built to withstand harsh conditions, the INSUMMCU2 MCU2A02V24 features a compact IP20-rated enclosure and wide temperature tolerance. Its ATEX/IECEx certification allows deployment in hazardous areas, such as oil refineries and chemical plants.

Enhanced Diagnostics: Real-time status indicators and event logging (up to 20 events) simplify troubleshooting. The module’s LED display provides instant visibility into motor health, while fault codes enable rapid root-cause analysis.

Scalable Communication: Integrates with ABB’s INSUM backplane systems via LON bus or Modbus RTU, and supports PROFIBUS DP through optional gateways. This flexibility ensures compatibility with legacy and modern control systems.

Application Areas

Industrial Automation: The INSUMMCU2 MCU2A02V24 controls motors in conveyor systems, packaging machinery, and material handling equipment, optimizing energy efficiency and reducing wear. Its closed-loop control capabilities are critical for precision tasks like bottling line synchronization.

Industrial Automation: The INSUMMCU2 MCU2A02V24 controls motors in conveyor systems, packaging machinery, and material handling equipment, optimizing energy efficiency and reducing wear. Its closed-loop control capabilities are critical for precision tasks like bottling line synchronization.

HVAC Systems: Deployed in fans, pumps, and chillers, the module ensures reliable operation while minimizing energy consumption. Its voltage monitoring and overload protection features are vital for maintaining consistent performance in HVAC networks.

Process Industries: In chemical and petrochemical plants, the INSUMMCU2 MCU2A02V24 manages motor-driven processes (e.g., agitators, compressors) with fail-safe operation. Its hazardous area certification makes it suitable for offshore platforms and onshore production facilities.

Water/Wastewater Treatment: Controls pumps and valves in treatment plants, ensuring efficient water distribution and wastewater processing. The module’s diagnostic tools help identify leaks or blockages proactively.

Food & Beverage Production: Supports hygienic process control in mixers, conveyors, and sterilization equipment. Its compact design and resistance to washdown environments make it ideal for food-grade applications.

Related Products

- ABB INSUM Gateway PROFIBUS-DP: Enables PROFIBUS DP connectivity for the INSUMMCU2 MCU2A02V24, expanding integration with PLCs and SCADA systems.

- ABB INSUM MMI: Man-machine interface for local parameter adjustment and status monitoring of INSUMMCU2 MCU2A02V24.

- ABB MCU2A02V2-4: Higher-current variant (2.0–63A) with extended voltage monitoring (380–690V AC), complementary for large-scale motor control centers.

- ABB System 800xA: Automation platform for centralized configuration and monitoring of INSUMMCU2 MCU2A02V24-based systems.

- ABB S800 I/O Modules: Complementary I/O modules (e.g., AI820, DI821) for expanding system functionality in complex automation setups.

Installation and Maintenance

Pre-Installation Preparation:

Ensure the control system is powered off and grounded. Verify compatibility with ABB’s INSUM backplane (version 3.0+) and install the latest INSUM configuration software. Clean the DIN rail and inspect the INSUMMCU2 MCU2A02V24 for physical damage. Configure network parameters (LON bus address, Modbus settings) via DIP switches or ABB’s INSUM toolchain before mounting.

Pre-Installation Preparation:

Ensure the control system is powered off and grounded. Verify compatibility with ABB’s INSUM backplane (version 3.0+) and install the latest INSUM configuration software. Clean the DIN rail and inspect the INSUMMCU2 MCU2A02V24 for physical damage. Configure network parameters (LON bus address, Modbus settings) via DIP switches or ABB’s INSUM toolchain before mounting.

Maintenance Recommendations:

Regularly review diagnostic data to monitor motor performance and detect anomalies (e.g., current spikes, voltage dips). Clean dust from the module’s vents quarterly to prevent overheating in high-dust environments. Perform annual functional tests of I/O channels and communication interfaces. Replace the module if persistent faults occur, following ABB’s environmental disposal guidelines. ABB offers global technical support for firmware updates and troubleshooting.

Regularly review diagnostic data to monitor motor performance and detect anomalies (e.g., current spikes, voltage dips). Clean dust from the module’s vents quarterly to prevent overheating in high-dust environments. Perform annual functional tests of I/O channels and communication interfaces. Replace the module if persistent faults occur, following ABB’s environmental disposal guidelines. ABB offers global technical support for firmware updates and troubleshooting.

Product Warranty

The ABB INSUMMCU2 MCU2A02V24 is backed by a 1-year warranty covering manufacturing defects. ABB provides 24/7 technical support, including software updates and emergency assistance for critical issues. With spot inventory and 3-day delivery after payment, customers benefit from rapid deployment and minimal downtime. Post-sales services include training on system integration and compliance with industry standards to optimize operational efficiency.

The ABB INSUMMCU2 MCU2A02V24 is backed by a 1-year warranty covering manufacturing defects. ABB provides 24/7 technical support, including software updates and emergency assistance for critical issues. With spot inventory and 3-day delivery after payment, customers benefit from rapid deployment and minimal downtime. Post-sales services include training on system integration and compliance with industry standards to optimize operational efficiency.

Abb INICT01 Infi 90 Bailey Transfer Module

INIET800 Monitor/Control by – ABB – BAILEY CONTROLS

ABB Bailey INIIT03 Net Transfer Module

IMSET01 ABB PLC module New IMSET01

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com