Description

Product Overview

The ABB INNPM12 is a high-performance process interface module designed for ABB’s AC 800M control system, serving as a critical link between controllers and field devices in industrial automation setups. As part of the S800 I/O family, this module enables seamless integration of analog and digital signals into process control networks, supporting real-time data acquisition and control for complex manufacturing and process applications. The INNPM12 is engineered to deliver reliable operation in harsh environments while ensuring compatibility with ABB’s comprehensive automation ecosystem.

The ABB INNPM12 is a high-performance process interface module designed for ABB’s AC 800M control system, serving as a critical link between controllers and field devices in industrial automation setups. As part of the S800 I/O family, this module enables seamless integration of analog and digital signals into process control networks, supporting real-time data acquisition and control for complex manufacturing and process applications. The INNPM12 is engineered to deliver reliable operation in harsh environments while ensuring compatibility with ABB’s comprehensive automation ecosystem.

Designed for standard (non-safety) process control, the INNPM12 supports up to 16 channels of mixed I/O (analog and digital) with configurable signal types, allowing flexible adaptation to diverse field requirements. Its hot-swappable design enables maintenance without system shutdown, minimizing downtime in critical operations. The module integrates with ABB’s System 800xA and Safety Builder platforms, facilitating unified configuration and monitoring of control and safety functions. With a rugged construction and wide operating temperature range, the INNPM12 is ideal for industries such as oil & gas, power generation, and chemical processing that demand robust and versatile I/O solutions.

The module’s high-speed communication capabilities (via PROFIBUS DP or Ethernet) ensure low-latency data transfer, while built-in diagnostics provide real-time visibility into channel status and system health. This combination of flexibility, reliability, and diagnostic precision makes the INNPM12 a cornerstone of modern process automation systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | INNPM12 |

| Manufacturer | ABB |

| Product Type | Process Interface Module (AC 800M Series) |

| I/O Channels | 16 channels (configurable as analog input/output or digital input/output) |

| Signal Types | Analog: 4-20 mA, 0-10 V; Digital: 24V DC (sink/source) |

| Communication Protocol | PROFIBUS DP V1, Ethernet (Modbus TCP, SNMP) |

| Power Supply | 24V DC (±20%), 150 mA (nominal) |

| Physical Dimensions | 105 mm (H) × 25 mm (W) × 175 mm (D) |

| Weight | 0.2 kg |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Certifications | CE, UL, cUL, ATEX (Zone 2), IECEx |

| Redundancy Support | Hardware redundancy (optional with dual module configuration) |

| Mounting | 35 mm DIN rail or direct chassis mounting |

Key Features and Advantages

Flexible I/O Configuration: The INNPM12 offers 16 configurable channels, allowing users to mix analog (4-20 mA/0-10 V) and digital (24V DC) signals per application needs. This adaptability reduces inventory requirements and simplifies system design for diverse process control scenarios.

Flexible I/O Configuration: The INNPM12 offers 16 configurable channels, allowing users to mix analog (4-20 mA/0-10 V) and digital (24V DC) signals per application needs. This adaptability reduces inventory requirements and simplifies system design for diverse process control scenarios.

High-Speed Communication: With support for PROFIBUS DP and Ethernet protocols, the module ensures low-latency data transfer (up to 12 Mbps on PROFIBUS) and seamless integration with PLCs, SCADA systems, and HMIs. Its real-time performance is critical for time-sensitive control loops.

Hot-Swappable Design: The module can be replaced without powering down the system, enabling maintenance during operation. This feature minimizes production interruptions in continuous processes, such as refineries or chemical plants.

Comprehensive Diagnostics: Built-in self-test functions and channel-level diagnostics (via LED indicators and system software) identify faults (e.g., open circuits, overvoltage) in real time. This proactive monitoring reduces troubleshooting time and enhances system reliability.

Rugged Industrial Performance: Rated for -25°C to +70°C operation and immune to electromagnetic interference, the INNPM12 thrives in harsh environments. Its compact 25 mm width optimizes cabinet space while meeting rigorous industrial standards (ATEX/IECEx for hazardous areas).

Application Areas

Oil & Gas Processing: The INNPM12 monitors and controls critical parameters in refineries, such as pressure, flow, and temperature in distillation columns. Its compatibility with hazardous area certifications makes it suitable for offshore platforms and onshore production facilities.

Oil & Gas Processing: The INNPM12 monitors and controls critical parameters in refineries, such as pressure, flow, and temperature in distillation columns. Its compatibility with hazardous area certifications makes it suitable for offshore platforms and onshore production facilities.

Power Generation: Deployed in thermal and renewable energy plants, the module interfaces with turbines, generators, and switchgear, enabling precise control of power output and grid integration. It supports analog signals from sensors and digital signals for breaker controls.

Chemical Manufacturing: In chemical reactors and processing lines, the INNPM12 manages feedstock flows, pH levels, and reaction temperatures. Its flexible I/O configuration adapts to diverse chemical processes, from batch to continuous operations.

Water/Wastewater Treatment: The module controls pumps, valves, and treatment tanks by processing analog signals from level sensors and digital signals from motor starters. It supports remote monitoring for water distribution networks and wastewater treatment plants.

Food & Beverage Production: The INNPM12 ensures hygienic process control in bottling lines and food processing equipment, handling analog signals from temperature sensors and digital signals for conveyor controls. Its rugged design withstands washdown environments.

Related Products

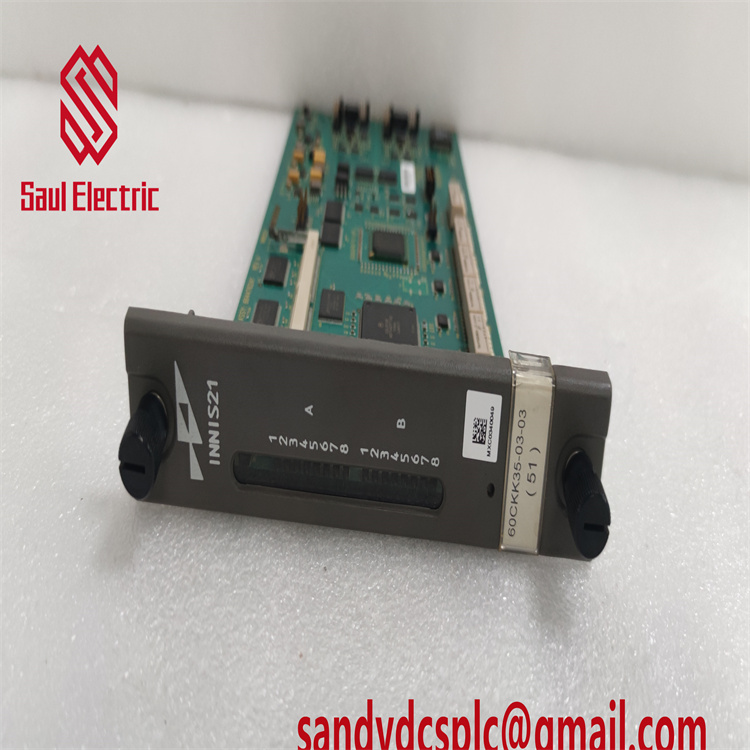

- ABB INNIS21: Safety interface module for SIL 3 applications, complementary to INNPM12 for integrated control-safety systems.

- ABB INNPM13: Upgraded version with enhanced processing power and support for more I/O channels, suitable for large-scale projects.

- ABB S800 I/O Modules: Series of specialized I/O modules (e.g., AI820, DI821) that pair with INNPM12 for expanded I/O capacity.

- ABB AC 800M Controllers: Process controllers (e.g., PM866, PM891) that communicate with INNPM12 to execute control logic.

- ABB System 800xA: Automation platform for configuring and monitoring INNPM12-based systems, enabling unified control across processes.

Installation and Maintenance

Pre-Installation Preparation:

Ensure the control system is powered off and grounded. Verify compatibility with ABB AC 800M chassis (version 3.0 or higher) and install the latest System 800xA software (v6.1+). Clean the DIN rail or chassis slot and inspect the INNPM12 for physical damage. Configure network parameters (PROFIBUS address, IP settings) via DIP switches or ABB’s configuration tools before installation.

Pre-Installation Preparation:

Ensure the control system is powered off and grounded. Verify compatibility with ABB AC 800M chassis (version 3.0 or higher) and install the latest System 800xA software (v6.1+). Clean the DIN rail or chassis slot and inspect the INNPM12 for physical damage. Configure network parameters (PROFIBUS address, IP settings) via DIP switches or ABB’s configuration tools before installation.

Maintenance Recommendations:

Regularly review diagnostic data in System 800xA to monitor channel health and identify trends (e.g., signal drift, connection issues). Clean dust from the module’s vents quarterly to prevent overheating in high-dust environments. Perform annual functional tests of I/O channels to ensure accuracy. Replace the module if LED indicators show persistent faults or if physical damage is detected, following ABB’s environmental disposal guidelines.

Regularly review diagnostic data in System 800xA to monitor channel health and identify trends (e.g., signal drift, connection issues). Clean dust from the module’s vents quarterly to prevent overheating in high-dust environments. Perform annual functional tests of I/O channels to ensure accuracy. Replace the module if LED indicators show persistent faults or if physical damage is detected, following ABB’s environmental disposal guidelines.

Product Warranty

The ABB INNPM12 is supported by a 1-year warranty covering manufacturing defects. ABB provides global technical support, including software updates, application engineering assistance, and 24/7 emergency service for critical issues. With spot inventory and 3-day delivery after payment, customers benefit from rapid deployment and minimal downtime. Post-sales support includes training on system integration and compliance with industry standards to optimize operational efficiency.

The ABB INNPM12 is supported by a 1-year warranty covering manufacturing defects. ABB provides global technical support, including software updates, application engineering assistance, and 24/7 emergency service for critical issues. With spot inventory and 3-day delivery after payment, customers benefit from rapid deployment and minimal downtime. Post-sales support includes training on system integration and compliance with industry standards to optimize operational efficiency.

Abb INICT01 Infi 90 Bailey Transfer Module

INIET800 Monitor/Control by – ABB – BAILEY CONTROLS

ABB Bailey INIIT03 Net Transfer Module

IMSET01 ABB PLC module New IMSET01

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com