Description

Product Overview

The

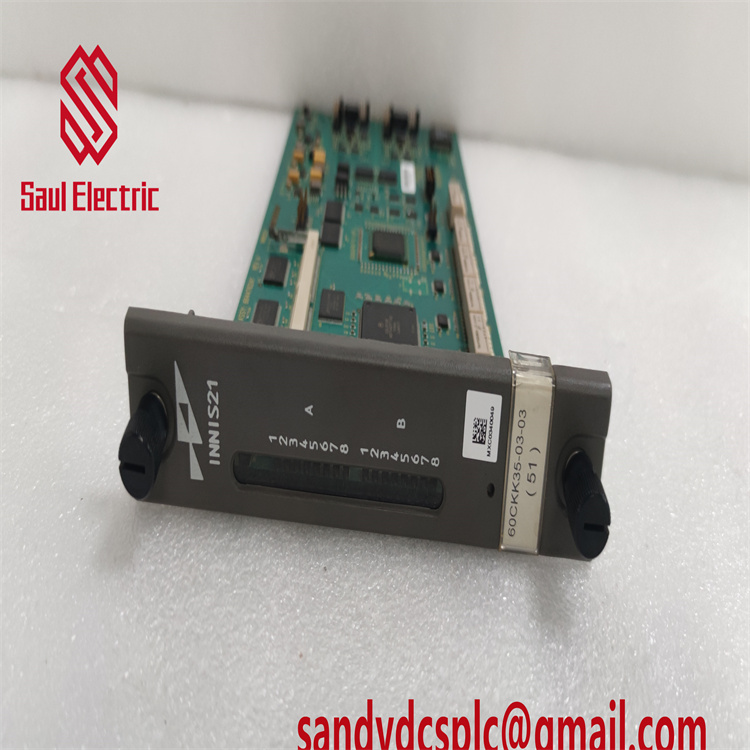

is a high-reliability safety interface module designed for ABB’s AC 800M control system, catering to safety-critical industrial applications. As part of the Safety Builder platform, this module serves as a bridge between standard control systems and safety-related I/O, enabling seamless integration of safety functions into process automation frameworks. The INNIS21 supports fail-safe communication protocols, ensuring secure data transfer while maintaining system integrity during critical operations.

is a high-reliability safety interface module designed for ABB’s AC 800M control system, catering to safety-critical industrial applications. As part of the Safety Builder platform, this module serves as a bridge between standard control systems and safety-related I/O, enabling seamless integration of safety functions into process automation frameworks. The INNIS21 supports fail-safe communication protocols, ensuring secure data transfer while maintaining system integrity during critical operations.

The

is a high-reliability safety interface module designed for ABB’s AC 800M control system, catering to safety-critical industrial applications. As part of the Safety Builder platform, this module serves as a bridge between standard control systems and safety-related I/O, enabling seamless integration of safety functions into process automation frameworks. The INNIS21 supports fail-safe communication protocols, ensuring secure data transfer while maintaining system integrity during critical operations.

is a high-reliability safety interface module designed for ABB’s AC 800M control system, catering to safety-critical industrial applications. As part of the Safety Builder platform, this module serves as a bridge between standard control systems and safety-related I/O, enabling seamless integration of safety functions into process automation frameworks. The INNIS21 supports fail-safe communication protocols, ensuring secure data transfer while maintaining system integrity during critical operations.

Engineered for SIL 3-certified systems, the INNIS21 facilitates real-time monitoring and control of safety loops, such as emergency shutdown (ESD) and fire & gas detection systems. Its dual-channel design with hardware redundancy minimizes downtime, while hot-swappable capabilities allow maintenance without process interruption. By combining advanced diagnostics with compact packaging, the module optimizes space in control cabinets while adhering to rigorous safety standards. This makes it ideal for industries where operational continuity and hazard mitigation are paramount, including oil & gas, chemical processing, and power generation.

The INNIS21 integrates seamlessly with ABB’s Safety Manager software, enabling intuitive configuration of safety logic and protocol mapping. Its rugged construction (rated for -25°C to +70°C operation) and immunity to electromagnetic interference further enhance its suitability for harsh industrial environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | INNIS21 |

| Manufacturer | ABB |

| Product Type | Safety Interface Module (AC 800M Series) |

| Safety Integrity Level | SIL 3 (IEC 61508/61511) |

| Communication Protocols | Safety over EtherNet/IP, PROFIsafe, Modbus RTU |

| I/O Channels | 2 x fail-safe digital input/output channels |

| Power Supply | 24V DC (±10%), 80 mA (nominal) |

| Physical Dimensions | 105 mm (H) × 25 mm (W) × 175 mm (D) |

| Weight | 0.18 kg |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Certifications | CE, UL, cUL, ATEX (Zone 2), IECEx |

| Redundancy Support | Hardware redundancy (dual channels) |

| Mounting | 35 mm DIN rail or direct chassis mounting |

Key Features and Advantages

SIL 3 Compliance: The INNIS21 meets the highest safety integrity standards, ensuring reliable operation in life-critical applications. Its fail-safe design prevents spurious trips and undetected faults, reducing the risk of unplanned shutdowns.

SIL 3 Compliance: The INNIS21 meets the highest safety integrity standards, ensuring reliable operation in life-critical applications. Its fail-safe design prevents spurious trips and undetected faults, reducing the risk of unplanned shutdowns.

Dual-Channel Redundancy: With independent signal paths for each channel, the module maintains functionality even if one channel fails. This hot-swappable redundancy eliminates the need for system downtime during maintenance.

Versatile Communication: Supporting multiple safety protocols (EtherNet/IP, PROFIsafe), the INNIS21 integrates with diverse control systems. It also enables seamless data exchange between safety PLCs and process controllers, enhancing system interoperability.

Advanced Diagnostics: Built-in self-test functions and real-time health monitoring identify potential issues (e.g., wiring faults, voltage fluctuations) before they escalate. Diagnostic information is accessible via the module’s LED indicators and ABB’s system software.

Space-Efficient Design: At just 25 mm width, the INNIS21 optimizes cabinet space while delivering robust safety performance. Its wide temperature range and rugged construction make it suitable for offshore, petrochemical, and heavy industry environments.

Application Areas

Oil & Gas Production: The INNIS21 safeguards upstream and downstream operations by managing ESD systems, wellhead controls, and pipeline pressure safety loops. Its explosion-proof certifications (ATEX/IECEx) make it ideal for hazardous areas.

Oil & Gas Production: The INNIS21 safeguards upstream and downstream operations by managing ESD systems, wellhead controls, and pipeline pressure safety loops. Its explosion-proof certifications (ATEX/IECEx) make it ideal for hazardous areas.

Chemical Processing: Deployed in reactor safety systems, the module monitors temperature/pressure excursions and triggers emergency shutdowns to prevent chemical leaks or thermal runaway. It also integrates with fire & gas detection networks in processing plants.

Power Generation: In thermal and nuclear power stations, the INNIS21 controls safety-critical functions like turbine trip systems, coolant flow monitoring, and generator protection relays, ensuring compliance with strict regulatory standards.

Pharmaceutical Manufacturing: The module supports sterile process control by managing safety interlocks in bioreactors and cleanroom environments, preventing contamination risks while maintaining production continuity.

Marine & Offshore: Installed on oil rigs and ships, the INNIS21 withstands harsh maritime conditions (salt spray, vibration) while overseeing safety systems for cargo handling, engine rooms, and emergency evacuation protocols.

Related Products

- ABB INNPM12: Process interface module for standard I/O in AC 800M systems, complementary to INNIS21 for integrated control-safety architectures.

- ABB INNIS14: Earlier-generation safety interface module with single-channel design, suitable for less complex safety loops.

- ABB INNIS25: Enhanced model with 4 fail-safe channels and higher data throughput for large-scale safety systems.

- ABB S800 I/O Safety Modules: Series of safety-rated I/O modules (e.g., DI821, DO820) that pair with INNIS21 for expanded safety I/O capacity.

- ABB Safety Builder Software: Configuration tool for programming safety logic in conjunction with INNIS21, enabling custom safety function design.

Installation and Maintenance

Pre-Installation Preparation:

Ensure the control system is powered off and grounded. Verify compatibility with ABB AC 800M chassis (version 3.2 or higher) and install the latest Safety Builder software (v6.1+). Clean the mounting rail and inspect the INNIS21 for physical damage. Configure network parameters (IP address, subnet mask) via the module’s DIP switches or ABB’s System Builder tool.

Pre-Installation Preparation:

Ensure the control system is powered off and grounded. Verify compatibility with ABB AC 800M chassis (version 3.2 or higher) and install the latest Safety Builder software (v6.1+). Clean the mounting rail and inspect the INNIS21 for physical damage. Configure network parameters (IP address, subnet mask) via the module’s DIP switches or ABB’s System Builder tool.

Maintenance Recommendations:

Regularly review diagnostic data via the system’s HMI to monitor module health (e.g., channel status, error counts). Clean dust from the module’s ventilation slots every 6 months to prevent overheating. Perform annual functional tests of safety loops to ensure compliance with SIL requirements. Replace the module if LED indicators show persistent faults or if physical damage is detected, following ABB’s recommended disposal procedures.

Regularly review diagnostic data via the system’s HMI to monitor module health (e.g., channel status, error counts). Clean dust from the module’s ventilation slots every 6 months to prevent overheating. Perform annual functional tests of safety loops to ensure compliance with SIL requirements. Replace the module if LED indicators show persistent faults or if physical damage is detected, following ABB’s recommended disposal procedures.

Product Warranty

The ABB INNIS21 is backed by a 1-year warranty covering material and workmanship defects. ABB provides global technical support, including firmware updates, application engineering assistance, and 24/7 emergency service for critical issues. With guaranteed spot inventory and 3-day delivery after payment, customers benefit from minimal lead times. Post-sales support includes training on safety system integration and compliance audits to ensure optimal performance.

The ABB INNIS21 is backed by a 1-year warranty covering material and workmanship defects. ABB provides global technical support, including firmware updates, application engineering assistance, and 24/7 emergency service for critical issues. With guaranteed spot inventory and 3-day delivery after payment, customers benefit from minimal lead times. Post-sales support includes training on safety system integration and compliance audits to ensure optimal performance.

Abb INICT01 Infi 90 Bailey Transfer Module

INIET800 Monitor/Control by – ABB – BAILEY CONTROLS

ABB Bailey INIIT03 Net Transfer Module

IMSET01 ABB PLC module New IMSET01

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com