Description

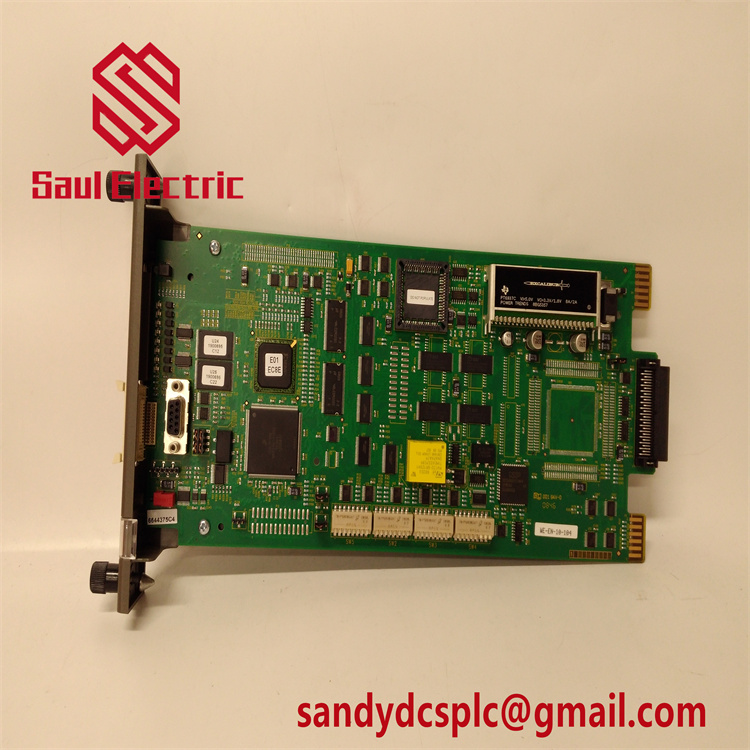

Product Overview

The ABB INIIT03 is a specialized interface terminal module designed for InfiNet industrial networks, forming a critical component of ABB’s Symphony Plus automation platform. Engineered to facilitate secure data transmission between field devices and control systems, this module serves as a physical connection point for InfiNet cables, enabling reliable communication in harsh industrial environments.

As a ruggedized terminal solution, the INIIT03 supports up to 32 nodes on a single InfiNet segment, ensuring seamless integration with controllers, I/O modules, and human-machine interfaces (HMIs). It features dual redundant ports for looped network configurations, enhancing system availability by eliminating single points of failure. The module operates on 24 V DC power and incorporates surge protection to withstand electrical disturbances, making it suitable for demanding applications in power generation, oil & gas, and process manufacturing.

The ABB INIIT03 simplifies network installation with its plug-and-play design, reducing commissioning time. Its compact form factor (102 x 160 x 40 mm) allows easy mounting in standard control panels, while the galvanically isolated architecture prevents ground loops and ensures signal integrity. By providing a robust physical layer for InfiNet networks, this module supports long-term system reliability and minimizes maintenance requirements.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | INIIT03 |

| Manufacturer | ABB |

| Product Type | InfiNet Interface Terminal Module |

| Network Protocol | InfiNet (proprietary ABB protocol) |

| Power Supply | 24 V DC ±15% |

| Power Consumption | <1.5 W |

| Physical Dimensions | 102 x 160 x 40 mm (4.0″ x 6.3″ x 1.6″) |

| Weight | 0.25 kg (0.55 lbs) |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Network Ports | 2 x InfiNet connectors (dual redundant) |

| Cable Support | RG-6 coaxial or Category 5 UTP |

| Max Network Length | 1.2 km (coaxial) / 100 m (UTP) |

| Certifications | CE, UL, CSA |

Main Features and Advantages

Redundant Network Architecture: The INIIT03 features dual InfiNet ports for looped network topologies, automatically switching to the backup path in case of cable failure. This redundancy ensures <10 ms failover time, critical for uninterrupted operation in process control systems.

Rugged Industrial Design: Built to withstand vibrations (up to 50 G) and electromagnetic interference, the module meets IEC 61800-3 standards for industrial drives. Its wide temperature range (-20°C to +60°C) makes it suitable for outdoor installations and extreme climates.

Easy Installation and Maintenance: The module’s snap-in mounting bracket and tool-less terminal connections reduce installation time by 50%. Hot-swappable functionality allows replacement without powering down the network, minimizing downtime during maintenance.

Signal Integrity Assurance: Galvanic isolation (2500 Vrms) and surge protection (10 kV) prevent voltage spikes from damaging connected devices. Built-in diagnostics monitor network health, with LED indicators for power, communication status, and fault conditions.

Scalable Network Infrastructure: Supporting up to 32 nodes per segment, the INIIT03 enables seamless expansion of InfiNet networks. It is compatible with ABB’s full range of InfiNet-compatible modules, allowing flexible system design for small to large-scale applications.

Application Areas

Power Generation Plants: The ABB INIIT03 is used in thermal, hydro, and nuclear power stations to connect distributed control systems (DCS) with field devices like turbine sensors and generator switches. Its redundancy features ensure continuous monitoring of critical parameters during power production.

Oil and Gas Facilities: In upstream and downstream operations, the module withstands harsh offshore conditions, enabling reliable communication between subsea sensors and onshore control rooms. It supports real-time data transmission for pipeline pressure monitoring and wellhead control.

Chemical and Pharmaceutical Processing: The module facilitates secure data exchange in cleanroom environments, connecting batch controllers with mixers, valves, and analyzers. Its corrosion-resistant housing meets FDA and cGMP standards for pharmaceutical applications.

Water and Wastewater Treatment: Deployed in pumping stations and treatment plants, the INIIT03 monitors flow meters, level sensors, and chemical dosing systems. Its long network reach (1.2 km) allows integration of remote field devices in large-scale water management systems.

Manufacturing Automation: In automotive and food & beverage production lines, the module coordinates conveyor systems, robotic arms, and quality inspection equipment. Its low latency (≤1 ms) ensures precise timing for high-speed manufacturing processes.

Related Products

- INIET800: InfiNet-to-Ethernet communication gateway, compatible with the INIIT03 for integrating legacy InfiNet networks with modern Ethernet systems.

- INICT01: InfiNet controller module that pairs with the INIIT03 for distributed control applications, offering 16 digital I/O channels.

- INIPS01: InfiNet power supply module, providing redundant 24 V DC power to the INIIT03 and connected devices.

- INICC01: InfiNet cable connector kit, including RG-6 coaxial cables and termination resistors for seamless INIIT03 installation.

- SPPA-T3000 DCS: ABB’s distributed control system that leverages the INIIT03 for robust InfiNet network infrastructure in power plant applications.

- DSQC607: Robotic interface module compatible with the INIIT03 for integrating industrial robots into InfiNet-controlled production lines.

- PFSK151: Fiber optic converter for extending InfiNet networks via the INIIT03, supporting distances up to 20 km.

Installation and Maintenance

Installation Preparation:

- Ensure the control panel is grounded and ventilated, with ambient temperature within -20°C to +60°C.

- Verify InfiNet cable type (RG-6 or Category 5) and terminate both ends with 75 Ω resistors as per INIIT03 specifications.

- Use anti-static gloves when handling the module to prevent ESD damage. Connect power leads (24 V DC) with insulated terminals, ensuring polarity is correct.

Maintenance Recommendations:

- Quarterly Inspections: Check for loose connections, frayed cables, or overheating using the module’s temperature indicator. Clean dust from vents with compressed air (≤2 bar pressure).

- Annual Testing: Use ABB’s Network Analyzer software to verify signal integrity, including voltage levels and data error rates. Replace worn-out cables or connectors promptly.

- Firmware Management: Update firmware every 18 months to incorporate bug fixes and security patches, following ABB’s official release notes.

- Redundancy Validation: Test dual-port failover functionality biannually by simulating a cable disconnection; the module should switch to the backup path within 10 ms.

- Environmental Monitoring: Ensure operating conditions do not exceed specified limits, especially in high-humidity or corrosive environments. Apply protective coatings to exposed connectors as needed.

- HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com