Description

Product Overview

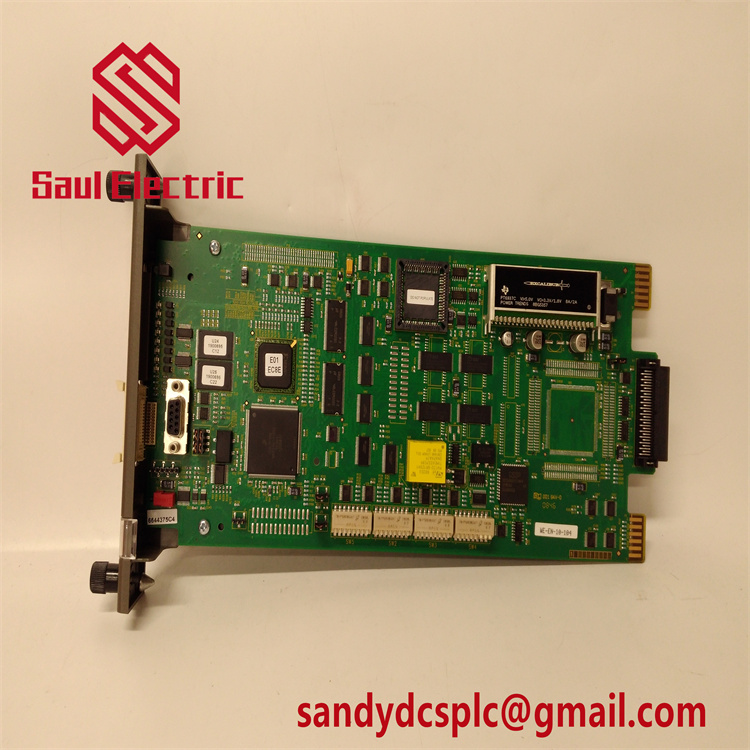

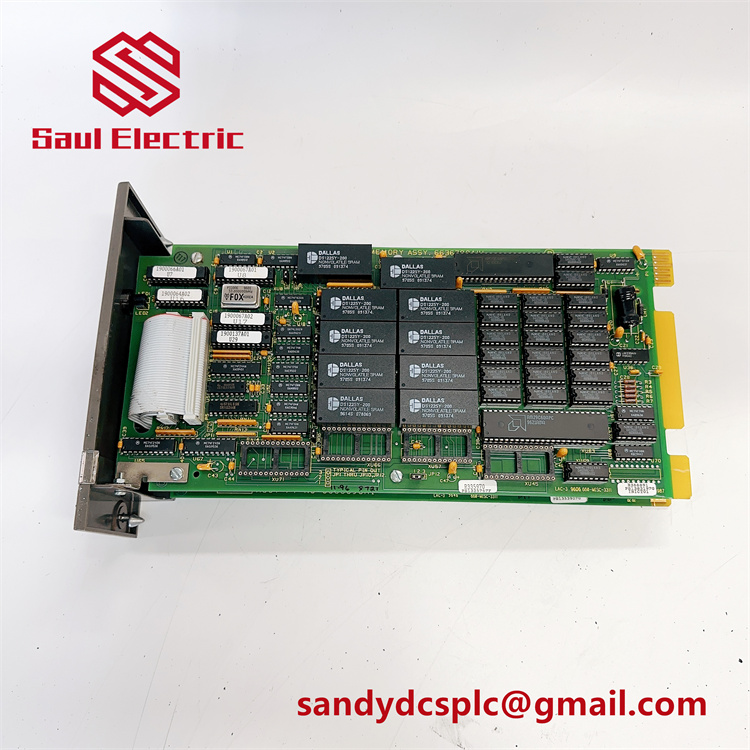

The ABB INIET800 is a high-performance communication module designed for industrial automation systems, specifically engineered to bridge InfiNet (ABB’s proprietary industrial network) with Ethernet-based systems. Belonging to the Symphony Plus platform, this module serves as a critical interface for integrating legacy Infi 90 systems with modern Ethernet networks, enabling seamless data exchange between control layers and enterprise-level infrastructure.

With support for protocols like Modbus TCP, EtherNet/IP, and ArcNet, the INIET800 facilitates real-time data transfer between field devices, controllers, and supervisory systems. It features dual Ethernet ports for redundant network configurations, ensuring high availability in mission-critical applications. The module operates on 24 V DC power and consumes only 6 W, making it energy-efficient for long-term industrial use. Its compact design (5.1 x 17.8 x 33.0 cm) allows easy integration into existing control cabinets, while the rugged construction withstands harsh environments with a temperature range of 0°C to 50°C.

The ABB INIET800 simplifies system migration by acting as a protocol converter, eliminating the need for complex hardware upgrades. It supports hot-swappable functionality, enabling maintenance without disrupting operations. By centralizing communication between InfiNet and Ethernet domains, this module enhances system scalability, reduces downtime, and provides a cost-effective solution for modernizing industrial automation architectures.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | INIET800 |

| Manufacturer | ABB |

| Product Type | Industrial Communication Module (InfiNet-to-Ethernet Gateway) |

| Communication Protocols | Modbus TCP, EtherNet/IP, ArcNet, RS-232 (19.2 kbps) |

| Power Supply | 24 V DC ±10% |

| Power Consumption | 6 W |

| Physical Dimensions | 5.1 x 17.8 x 33.0 cm (2.0″ x 7.0″ x 13.0″) |

| Weight | 0.3 kg (0.66 lbs) |

| Operating Temperature | 0°C to 50°C |

| Storage Temperature | -20°C to 70°C |

| Network Ports | 2 x Ethernet (RJ45), 1 x RS-232 |

| Redundancy Support | Dual Ethernet ports for redundant network connections |

| Certifications | CE, UL |

Main Features and Advantages

Multi-Protocol Conversion: The INIET800 seamlessly translates between InfiNet and Ethernet protocols, allowing legacy systems to integrate with modern industrial IT networks. This flexibility supports hybrid architectures where both traditional and advanced technologies coexist.

High Reliability: Its dual Ethernet ports enable redundant communication paths, minimizing downtime in case of network failures. The module also features built-in hardware and software watchdog timers, ensuring stable operation even in electrically noisy environments.

Compact and Rugged Design: With dimensions of 5.1 x 17.8 x 33.0 cm and a weight of 0.3 kg, the INIET800 fits into standard control cabinets. Its industrial-grade construction resists vibrations, dust, and temperature fluctuations, making it suitable for oil and gas, power generation, and manufacturing sectors.

Hot-Swap Capability: Field-replaceable components allow maintenance without powering down the system, reducing operational disruptions. This feature is critical for applications requiring continuous uptime, such as process control and remote monitoring.

Scalability: The module supports up to 32 nodes on the InfiNet side and unlimited Ethernet devices, accommodating expanding system requirements. It also provides transparent data transmission, enabling direct integration with third-party SCADA or ERP systems.

Application Areas

Process Industry Modernization: The INIET800 is widely used to upgrade legacy Infi 90 systems in chemical plants and water treatment facilities, allowing them to communicate with modern HMIs and cloud-based analytics platforms. For example, it can bridge InfiNet-connected valves and sensors with an Ethernet-based supervisory system for real-time performance optimization.

Remote Monitoring and Control: In oil and gas installations, the module enables remote access to InfiNet devices via Ethernet, facilitating predictive maintenance and reducing site visits. Its support for GPRS and SMS communication adds an extra layer of connectivity for offsite operations.

Manufacturing Automation: In automotive assembly lines, the INIET800 integrates InfiNet-based PLCs with Ethernet-connected robots and quality inspection systems, ensuring synchronized production and data-driven decision-making.

Power Generation: In thermal power plants, the module connects InfiNet-based turbine control systems with Ethernet networks for grid stability monitoring and energy management. Its wide temperature range (0°C to 50°C) suits both indoor and outdoor applications.

Building Automation: The INIET800 can interface InfiNet-based HVAC controllers with Ethernet networks, enabling centralized energy management in smart buildings. This integration reduces energy consumption by optimizing heating and cooling schedules.

Related Products

- SPIET800: A 升级版 communication module designed for Symphony Plus systems, offering higher data throughput and expanded protocol support compared to the INIET800.

- GJR5253100R0268: ArcNet communication card compatible with the INIET800 for legacy network integration.

- AC800M Controller: ABB’s modular process controller that pairs with the INIET800 for hybrid InfiNet/Ethernet control systems.

- SDCS-CON-4 Board: Optional interface board for advanced tachometer and motor control integration.

- DSAI130: Analog input module for expanding the INIET800’s data acquisition capabilities in process control applications.

- DSAO120A: Analog output module for precise control of actuators connected via the INIET800.

- SPPA-T3000: ABB’s distributed control system (DCS) that leverages the INIET800 for InfiNet-to-Ethernet integration in power plants.

Installation and Maintenance

Installation Preparation:

- Ensure the control cabinet is properly grounded and ventilated.

- Verify the INIET800’s compatibility with existing InfiNet devices and Ethernet switches.

- Use anti-static wrist straps during handling to prevent electrostatic discharge damage.

- Connect the module’s 24 V DC power supply and configure the Ethernet ports using ABB’s Engineering Studio software.

Maintenance Recommendations:

- Visual Inspection: Quarterly check for loose connections, dust accumulation, or physical damage. Clean vents and connectors with compressed air.

- Firmware Updates: Regularly update firmware to access new features and security patches, following ABB’s official guidelines.

- Redundancy Testing: Biannually test the dual Ethernet ports’ failover functionality to ensure seamless network 切换.

- Battery Replacement: Replace the backup battery (if applicable) every 5 years to preserve configuration data.

- Documentation Review: Annually audit system diagrams and settings to ensure alignment with operational requirements.

Product Warranty

ABB guarantees the INIET800 against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers repairs or replacements for non-operational units, excluding damage caused by improper use or unauthorized modifications. Customers receive 24/7 technical support via phone and online portals, ensuring prompt issue resolution. For mission-critical applications, optional extended warranties and proactive maintenance plans are available to further reduce downtime risks. ABB’s global network of certified partners provides local expertise and rapid replacement services, ensuring seamless integration and long-term system reliability.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com