Description

Product Overview

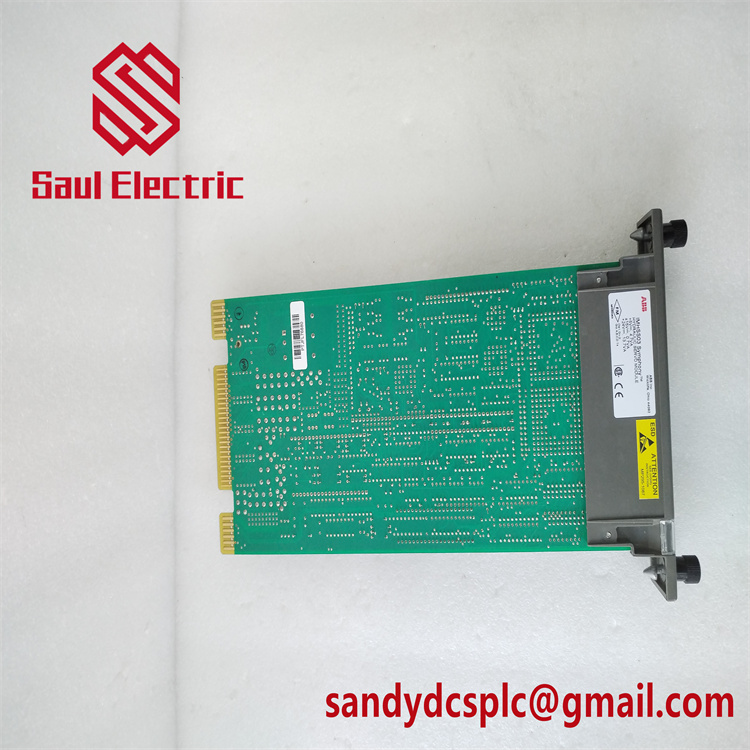

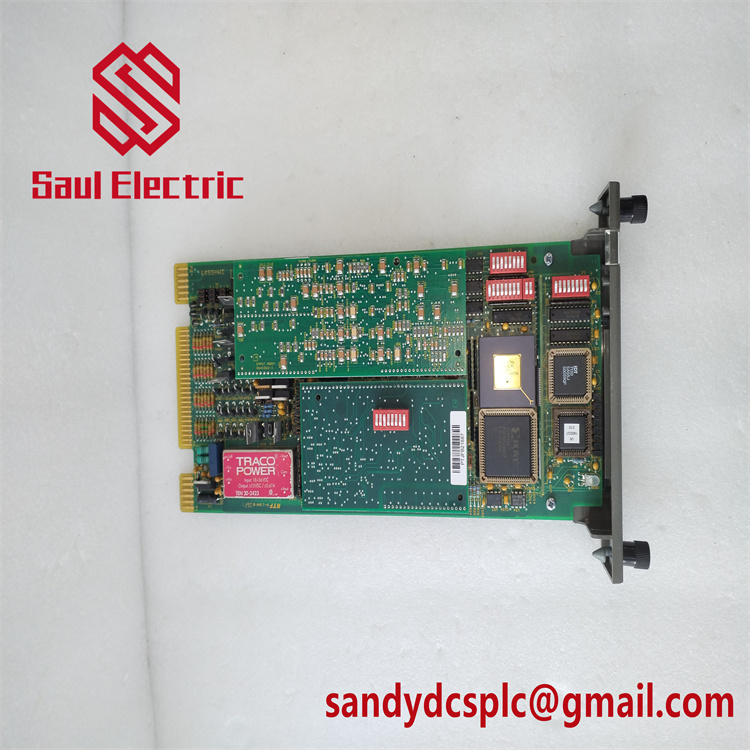

The ABB IMSET01 is a high-precision timing module designed for industrial automation systems, specializing in event sequence synchronization and timestamping. It serves as a critical component in ABB’s Bailey Infi 90 DCS and Symphony Plus platforms, ensuring accurate recording of events (e.g., alarms, equipment status changes) with microsecond-level precision. The module interfaces with field devices via digital inputs and communicates with control systems through Modbus RTU or InfiNet protocols, providing a unified time reference across distributed systems.

Featuring dual redundant power supplies and hot-swappable architecture, the IMSET01 ensures continuous operation in mission-critical environments. Its IP20-rated enclosure protects against dust and debris, while a wide temperature range (-25°C to +70°C) ensures reliability in harsh industrial settings. The module supports external time synchronization (GPS, NTP, IRIG-B) to maintain consistent timestamps across geographically dispersed systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IMSET01 |

| Manufacturer | ABB |

| Product Type | SOE Time Keeper Module |

| Timing Accuracy | ±1 ms (with external synchronization) |

| Event Capture | Up to 16 digital inputs (24 V DC) with configurable debounce filters |

| Communication Protocols | Modbus RTU (RS-485), InfiNet (1 Mbps) |

| Power Supply | 24 V DC (±15%), redundant inputs |

| Operating Temperature | -25°C to +70°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, ROHS |

Main Features and Advantages

Precision Event Timestamping:

The IMSET01 records event occurrences with microsecond-level accuracy, enabling detailed analysis of system behavior during anomalies. Its time synchronization capabilities ensure consistent timestamps across multiple modules, critical for coordinating actions in complex processes like power grid fault analysis or manufacturing line optimization.

The IMSET01 records event occurrences with microsecond-level accuracy, enabling detailed analysis of system behavior during anomalies. Its time synchronization capabilities ensure consistent timestamps across multiple modules, critical for coordinating actions in complex processes like power grid fault analysis or manufacturing line optimization.

Flexible Configuration:

Users can program event triggers (rising/falling edges, pulse duration) and logic operations (AND/OR/NOT) via ABB’s Control Builder M software. The module supports customizable event prioritization and data logging intervals, allowing tailored solutions for applications ranging from basic monitoring to advanced predictive maintenance.

Users can program event triggers (rising/falling edges, pulse duration) and logic operations (AND/OR/NOT) via ABB’s Control Builder M software. The module supports customizable event prioritization and data logging intervals, allowing tailored solutions for applications ranging from basic monitoring to advanced predictive maintenance.

Reliable Redundancy:

With dual-port communication and redundant power inputs, the IMSET01 minimizes downtime in high-availability systems. Its self-diagnostic functions continuously monitor hardware health, with LED indicators providing real-time status updates for power, communication, and I/O channels.

With dual-port communication and redundant power inputs, the IMSET01 minimizes downtime in high-availability systems. Its self-diagnostic functions continuously monitor hardware health, with LED indicators providing real-time status updates for power, communication, and I/O channels.

Seamless Integration:

The module integrates with ABB’s IMRIO02 remote I/O slave for extended input capacity and pairs with the IMMFP12 processor for centralized data management. Its Modbus RTU interface enables compatibility with third-party SCADA systems, while DIN rail mounting simplifies installation in standard control cabinets.

The module integrates with ABB’s IMRIO02 remote I/O slave for extended input capacity and pairs with the IMMFP12 processor for centralized data management. Its Modbus RTU interface enables compatibility with third-party SCADA systems, while DIN rail mounting simplifies installation in standard control cabinets.

Application Areas

Power Generation:

The IMSET01 tracks breaker trips, generator faults, and protection relay actions in substations and power plants. Its precise timing helps analyze fault sequences during grid disturbances, ensuring compliance with IEEE C37.111 standards for event recording.

The IMSET01 tracks breaker trips, generator faults, and protection relay actions in substations and power plants. Its precise timing helps analyze fault sequences during grid disturbances, ensuring compliance with IEEE C37.111 standards for event recording.

Oil & Gas:

In offshore platforms and refineries, the module monitors valve position changes, ESD system activations, and safety instrumented function (SIF) executions. Its ATEX/IECEx certification allows deployment in Zone 1 hazardous areas.

In offshore platforms and refineries, the module monitors valve position changes, ESD system activations, and safety instrumented function (SIF) executions. Its ATEX/IECEx certification allows deployment in Zone 1 hazardous areas.

Manufacturing Automation:

For automotive assembly lines and chemical plants, the IMSET01 synchronizes robot motion commands, quality inspection triggers, and material handling events. Its high-response frequency (500 Hz) supports real-time adjustments in high-speed packaging processes.

For automotive assembly lines and chemical plants, the IMSET01 synchronizes robot motion commands, quality inspection triggers, and material handling events. Its high-response frequency (500 Hz) supports real-time adjustments in high-speed packaging processes.

Process Industries:

In pharmaceutical and food processing, the module records batch start/end times, temperature excursions, and operator interventions. Its non-volatile memory preserves event logs for compliance with FDA 21 CFR Part 11 and ISO 22000 traceability requirements.

In pharmaceutical and food processing, the module records batch start/end times, temperature excursions, and operator interventions. Its non-volatile memory preserves event logs for compliance with FDA 21 CFR Part 11 and ISO 22000 traceability requirements.

Related Products

- ABB IMRIO02: Remote I/O Slave Module for expanding digital input capacity.

- ABB IMMFP12: Multifunctional Processor Module for centralized event data storage and analysis.

- ABB IMSED01: ESD Safety Module that uses IMSET01 timestamps for fail-safe shutdown sequence validation.

- ABB IMFEC12: Analog Input Module for integrating process variable data with event timelines.

- ABB IMTAI01: Intrinsically Safe Terminal Block for connecting field devices in hazardous environments.

Installation and Maintenance

Installation Guidelines:

- Mount the IMSET01 on a DIN rail using M4 screws (torque 1.5–2.5 N·m) in a ventilated cabinet.

- Connect shielded cables to the NTMP01 termination unit for power and communication.

- Configure the module’s node address and time synchronization parameters via Control Builder M software.

Maintenance Recommendations:

- Perform quarterly functional tests to verify timestamp accuracy using ABB’s diagnostic tools.

- Clean air vents with compressed air every six months to prevent dust accumulation.

- Replace battery-backed RAM every 5 years to ensure configuration retention during power outages.

- Validate ground continuity (≤1 Ω) and power supply stability (24 V DC ±10%) during annual inspections.

Product Guarantee

ABB guarantees the IMSET01 against defects in materials and workmanship for 1 year, covering free repair or replacement of faulty components. Customers receive 24/7 technical support for configuration and troubleshooting, with remote access capabilities via secure VPN. ABB’s Extended Service Agreement offers proactive firmware updates, priority spare parts delivery, and compliance audits for up to 5 years, ensuring long-term system reliability.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com