Description

Product Overview

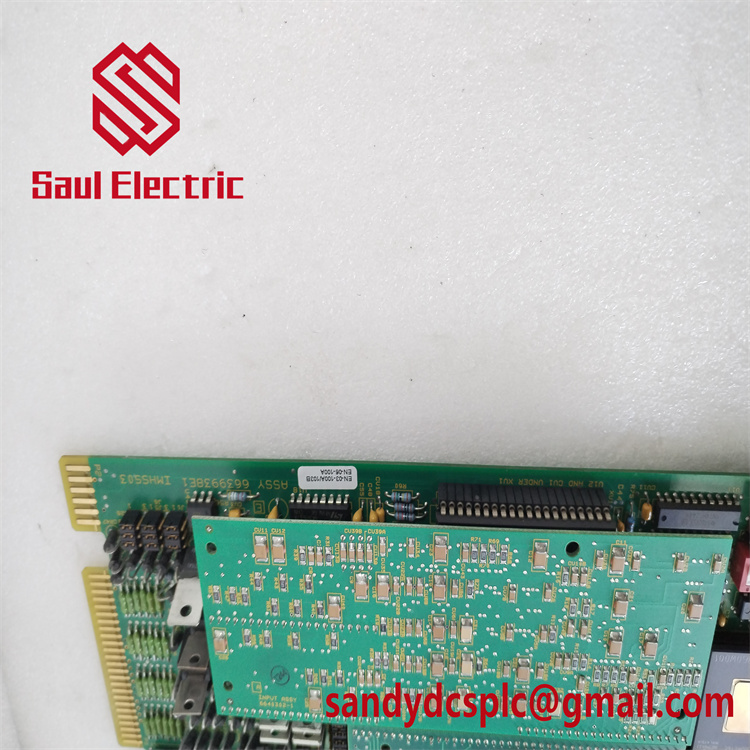

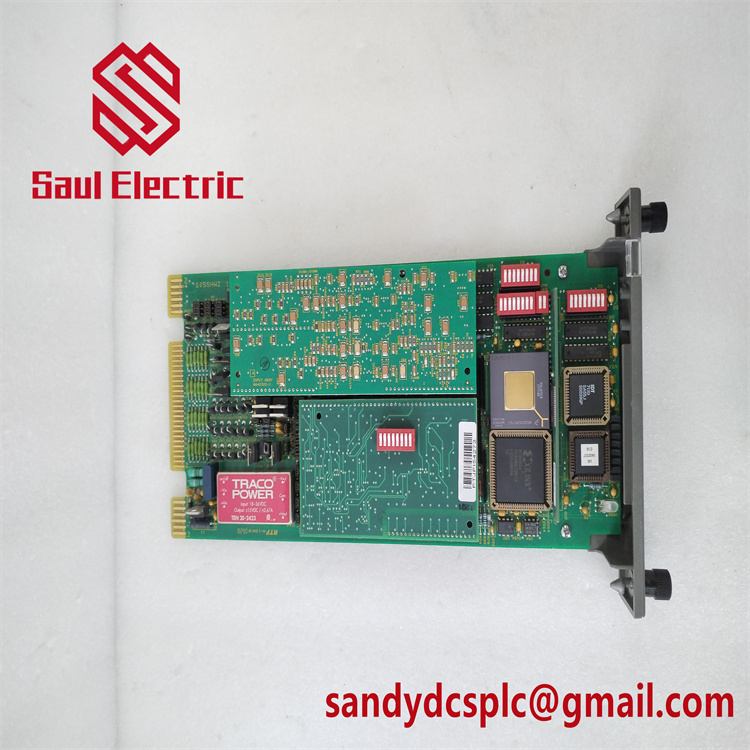

The ABB IMSED01 is a dedicated Emergency Shutdown (ESD) safety module designed for ABB’s Bailey Infi 90 DCS and Symphony Plus platforms. It serves as the core component of safety-critical systems, providing fail-safe emergency shutdown capabilities in industrial environments. The module adheres to IEC 61508 and SIL 3 safety integrity standards, ensuring rapid response to hazardous conditions (e.g., fire, overpressure, equipment failure) by executing pre-programmed shutdown sequences.

The IMSED01 integrates dual-channel redundancy (2oo3D architecture) and self-diagnostic functions to minimize false trips and undetected failures. It interfaces with field devices (emergency pushbuttons, flame detectors, pressure switches) via intrinsically safe (IS) I/O channels and communicates with the control system via InfiNet or Modbus protocols. Its hot-swappable design allows maintenance without disrupting safety loops, while the enclosure with IP20 protection ensures durability in harsh industrial settings.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IMSED01 |

| Manufacturer | ABB |

| Product Type | ESD Safety Module, SIL 3 Certified |

| Safety Integrity Level | SIL 3 (IEC 61508), Type A |

| Architecture | 2oo3D (2-out-of-3 with diagnostic coverage) |

| I/O Channels | 16 digital inputs (24 V DC), 8 digital outputs (relay/transistor), 4 analog inputs |

| Communication | InfiNet (1 Mbps), Modbus RTU (RS-485, up to 19.2 kbps) |

| Power Supply | 24 V DC (±15%), redundant power inputs |

| Operating Temperature | -40°C to +60°C |

| Humidity | 5–95% non-condensing |

| Certifications | CE, UL, SIL 3 (TÜV), ATEX (Ex d IIC T6), IECEx |

Main Features and Advantages

Safety-Critical Design:

The IMSED01 prioritizes safety with fault tolerance (e.g., single-point failure immunity) and diagnostic coverage >99% for critical circuits. Its hardwired emergency shutdown paths bypass software logic during catastrophic failures, ensuring deterministic response within <10 ms. The module supports voting logic (1oo2, 2oo3) for input signals to reduce nuisance trips in redundant sensor configurations.

The IMSED01 prioritizes safety with fault tolerance (e.g., single-point failure immunity) and diagnostic coverage >99% for critical circuits. Its hardwired emergency shutdown paths bypass software logic during catastrophic failures, ensuring deterministic response within <10 ms. The module supports voting logic (1oo2, 2oo3) for input signals to reduce nuisance trips in redundant sensor configurations.

Intrinsically Safe Interfaces:

All I/O channels comply with IEC 60079-11 intrinsic safety standards, allowing direct connection to field devices in hazardous areas (Zone 1/21). The module’s galvanic isolation (2500 Vrms) prevents ground loops and protects against transient surges, while channel-by-channel fusing safeguards against short circuits.

All I/O channels comply with IEC 60079-11 intrinsic safety standards, allowing direct connection to field devices in hazardous areas (Zone 1/21). The module’s galvanic isolation (2500 Vrms) prevents ground loops and protects against transient surges, while channel-by-channel fusing safeguards against short circuits.

Flexible Programming:

Using ABB’s Safety Builder M software (based on IEC 61131-3), users can configure shutdown logic, timer functions, and alarm priorities. The module supports ladder diagram (LD), function block diagram (FBD), and structured text (ST) programming languages, with built-in libraries for standard safety functions (e.g., emergency stop, process trip, manual reset).

Using ABB’s Safety Builder M software (based on IEC 61131-3), users can configure shutdown logic, timer functions, and alarm priorities. The module supports ladder diagram (LD), function block diagram (FBD), and structured text (ST) programming languages, with built-in libraries for standard safety functions (e.g., emergency stop, process trip, manual reset).

Real-Time Monitoring:

Front-panel LED indicators display channel status, system health, and alarm conditions. The module integrates the IMRIO02 remote I/O slave for extended I/O capacity and communicates with the IMMFP12 processor for central data logging. Its SNMP interface enables remote monitoring via SCADA systems, while non-volatile memory preserves configuration during power outages.

Front-panel LED indicators display channel status, system health, and alarm conditions. The module integrates the IMRIO02 remote I/O slave for extended I/O capacity and communicates with the IMMFP12 processor for central data logging. Its SNMP interface enables remote monitoring via SCADA systems, while non-volatile memory preserves configuration during power outages.

Application Areas

Oil & Gas Industry:

The IMSED01 serves as the core ESD system in refineries, offshore platforms, and pipelines, monitoring pressure transmitters, flame detectors, and toxic gas sensors. It triggers shutdown of compressors, pumps, and valves in the event of leaks or explosions, adhering to API 556 and ISO 13702 safety standards.

The IMSED01 serves as the core ESD system in refineries, offshore platforms, and pipelines, monitoring pressure transmitters, flame detectors, and toxic gas sensors. It triggers shutdown of compressors, pumps, and valves in the event of leaks or explosions, adhering to API 556 and ISO 13702 safety standards.

Power Generation:

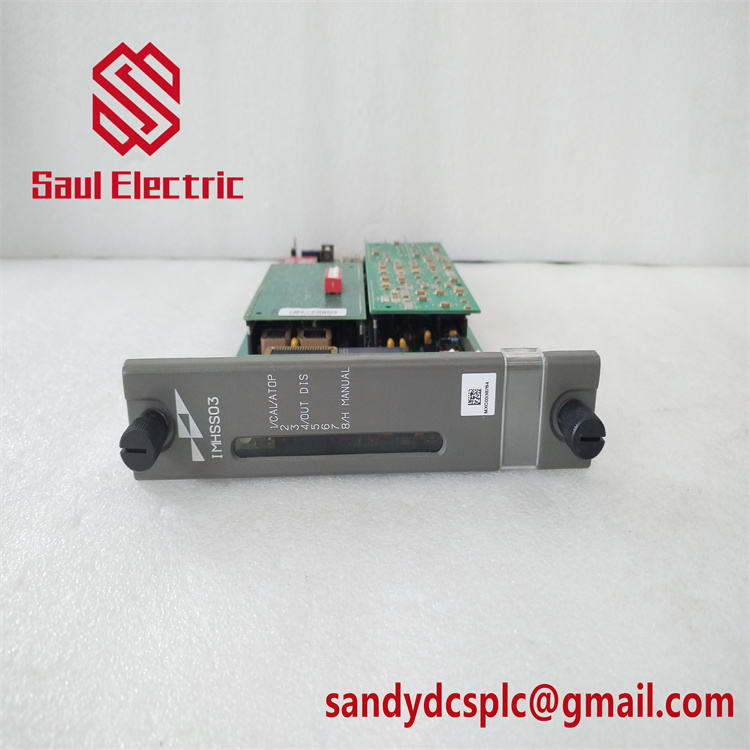

In thermal power plants, the module safeguards turbines and boilers by monitoring vibration sensors, overtemperature alarms, and lubrication system failures. It interfaces with the IMHSS03 hydraulic servo module to rapidly close steam valves during emergency stops, preventing overspeeding or mechanical damage.

In thermal power plants, the module safeguards turbines and boilers by monitoring vibration sensors, overtemperature alarms, and lubrication system failures. It interfaces with the IMHSS03 hydraulic servo module to rapidly close steam valves during emergency stops, preventing overspeeding or mechanical damage.

Chemical & Petrochemical Plants:

For processes involving flammable or toxic materials, the IMSED01 controls reactor emergency cooling systems, relief valve actuators, and fire suppression systems. Its ATEX/IECEx certification allows deployment in Zone 1 explosive atmospheres (Gas Groups IIA, IIB, IIC).

For processes involving flammable or toxic materials, the IMSED01 controls reactor emergency cooling systems, relief valve actuators, and fire suppression systems. Its ATEX/IECEx certification allows deployment in Zone 1 explosive atmospheres (Gas Groups IIA, IIB, IIC).

Marine & Offshore:

On ships and rigs, the module manages engine room ESD systems, hull leak detection, and life support system shutdowns. Its shock resistance (50 G, 11 ms) and vibration tolerance (2–200 Hz, 2 g) meet maritime standards (DNV GL, Lloyd’s Register).

On ships and rigs, the module manages engine room ESD systems, hull leak detection, and life support system shutdowns. Its shock resistance (50 G, 11 ms) and vibration tolerance (2–200 Hz, 2 g) meet maritime standards (DNV GL, Lloyd’s Register).

Related Products

- ABB IMRI01: Remote I/O Master Module for expanding I/O capacity of the IMSED01.

- ABB IMMFP12: Multifunctional Processor Module for integrating ESD logic with process control.

- ABB IMFEC12: Analog Input Module for high-precision monitoring of process variables (temperature, pressure).

- ABB IMDS014: Digital Output Module for discrete control of valves and motors in ESD loops.

- ABB IMHSS03: Hydraulic Servo Module for turbine speed and valve position control during normal and emergency operations.

Installation and Maintenance

Installation Requirements:

- Mount the IMSED01 on a DIN rail in a ventilated control cabinet (IP54 or higher) to prevent dust ingress.

- Separate power and signal cables by at least 10 cm to minimize EMI interference.

- Terminate field wires using the IMTAI01 intrinsically safe terminal block for hazardous area applications.

- Configure the module’s node address and safety parameters via Safety Builder M software before commissioning.

Maintenance Procedures:

- Perform annual functional safety tests (e.g., input/output response, self-diagnostic accuracy) using ABB’s test tools.

- Replace battery-backed RAM every 5 years to preserve configuration data.

- Inspect relay contacts (for output channels) every 2 years and replace if arcing or pitting is detected.

- Verify ground continuity (≤1 Ω) and power supply voltage stability (24 V DC ±10%) during routine checks.

Product Guarantee

ABB guarantees the IMSED01 against safety-related failures for 1 year under normal use, with compliance to SIL 3 standards validated by TÜV. The warranty covers free repair or replacement of defective components, supported by ABB’s Safety Lifecycle Services for ongoing verification (e.g., safety integrity reviews, firmware updates). Customers receive 24/7 emergency support for safety system disruptions, with priority access to certified technicians for on-site troubleshooting.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com