Description

Product Overview

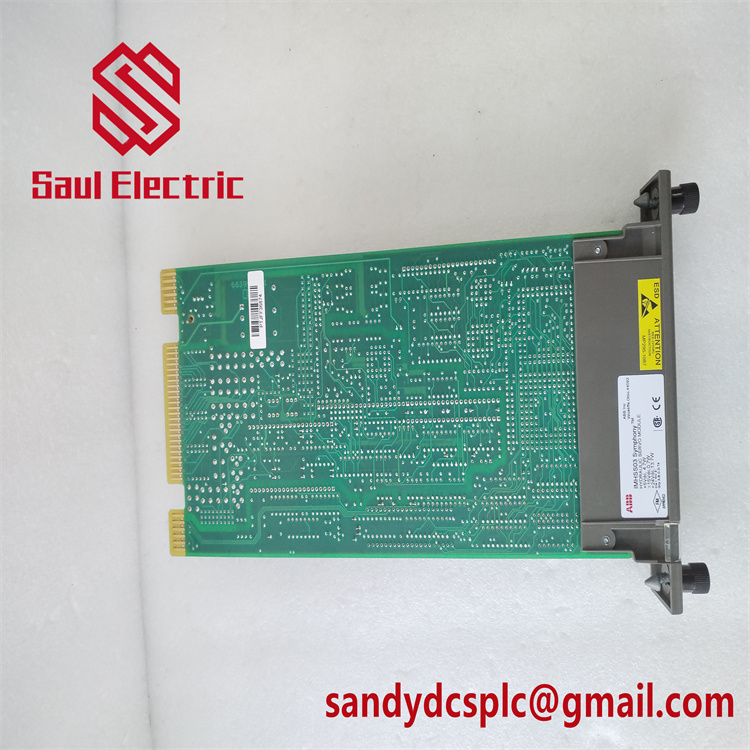

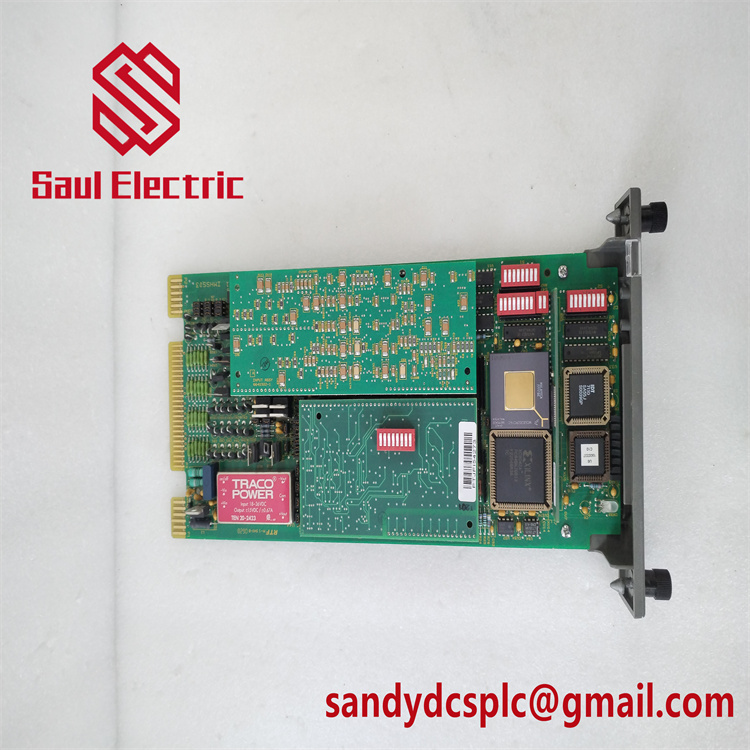

The ABB IMRIO02 is a remote I/O slave module designed for ABB’s Bailey Infi 90 distributed control system (DCS) and Symphony Plus platforms. It serves as a critical link between field devices (sensors, actuators) and the central control system, enabling real-time data acquisition and actuation in industrial automation. The module supports Infi 90 proprietary protocols (e.g., InfiNet) and RS-485 for seamless integration with master modules like the IMRI01 and processors such as the IMMFP12111421.

Featuring a modular design, the IMRIO02 allows flexible configuration of up to 32 I/O points (analog, digital, or pulse) through expandable I/O cards21. Its hot-swappable architecture enables maintenance without system downtime, while dual redundancy support ensures continuous operation in mission-critical environments like power plants and oil refineries. The module’s IP20-rated enclosure protects against dust and debris, and it operates reliably within a -40°C to +70°C temperature range714.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IMRIO02 |

| Manufacturer | ABB |

| Product Type | Remote I/O Slave Module |

| Communication Protocols | Infi 90 InfiNet, RS-485 |

| I/O Capacity | Up to 32 points (configurable via I/O cards) |

| Power Supply | 24 V DC (±10%) primary, +5 V DC / ±15 V DC auxiliary |

| Data Transfer Rate | Up to 1 Mbps (InfiNet), 19.2 kbps (RS-485) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 5–95% non-condensing |

| Physical Dimensions | 17.8 cm (H) × 5.1 cm (W) × 33.0 cm (D) |

| Weight | 0.4 kg |

| Certifications | CE, UL, ROHS |

Main Features and Advantages

Flexible I/O Configuration:

The IMRIO02 supports a wide range of analog (4–20 mA, ±10 V), digital (24 V DC), and pulse inputs/outputs, allowing integration with diverse field devices. Its modular I/O cards (e.g., IMDS014 digital outputs, IMFEC12 analog inputs) enable scalable system expansion for applications ranging from basic monitoring to complex process control721.

The IMRIO02 supports a wide range of analog (4–20 mA, ±10 V), digital (24 V DC), and pulse inputs/outputs, allowing integration with diverse field devices. Its modular I/O cards (e.g., IMDS014 digital outputs, IMFEC12 analog inputs) enable scalable system expansion for applications ranging from basic monitoring to complex process control721.

Reliable Communication:

As part of the Infi 90 DCS, the IMRIO02 communicates with the master control system via InfiNet protocol, ensuring low-latency data exchange. Its RS-485 interface supports integration with third-party devices, while dual-port redundancy safeguards against communication failures1114.

As part of the Infi 90 DCS, the IMRIO02 communicates with the master control system via InfiNet protocol, ensuring low-latency data exchange. Its RS-485 interface supports integration with third-party devices, while dual-port redundancy safeguards against communication failures1114.

Industrial-Grade Durability:

Engineered for harsh environments, the module features a vibration-resistant chassis and wide temperature tolerance (-40°C to +70°C). Its EMI/EMC compliance ensures stable performance near high-voltage equipment, and the IP20 enclosure protects against dust and solid particles714.

Engineered for harsh environments, the module features a vibration-resistant chassis and wide temperature tolerance (-40°C to +70°C). Its EMI/EMC compliance ensures stable performance near high-voltage equipment, and the IP20 enclosure protects against dust and solid particles714.

Easy Integration:

The IMRIO02 mounts directly onto a DIN rail and connects to the master module via shielded cables. Configuration is simplified using ABB’s Control Builder M software, which supports remote parameter adjustment and diagnostic monitoring1421.

The IMRIO02 mounts directly onto a DIN rail and connects to the master module via shielded cables. Configuration is simplified using ABB’s Control Builder M software, which supports remote parameter adjustment and diagnostic monitoring1421.

Application Areas

Power Generation:

The IMRIO02 controls turbine auxiliary systems (e.g., lubrication pumps, cooling fans) and interfaces with IMHSS03 hydraulic servo modules for steam turbine speed regulation. Its redundancy capabilities ensure uninterrupted operation during grid synchronization714.

The IMRIO02 controls turbine auxiliary systems (e.g., lubrication pumps, cooling fans) and interfaces with IMHSS03 hydraulic servo modules for steam turbine speed regulation. Its redundancy capabilities ensure uninterrupted operation during grid synchronization714.

Oil & Gas:

In refineries and offshore platforms, the module manages pipeline pressure sensors, valve actuators, and ESD (Emergency Shutdown) systems. Its explosion-proof design (Class I, Div 2) makes it suitable for hazardous environments2122.

In refineries and offshore platforms, the module manages pipeline pressure sensors, valve actuators, and ESD (Emergency Shutdown) systems. Its explosion-proof design (Class I, Div 2) makes it suitable for hazardous environments2122.

Manufacturing Automation:

The IMRIO02 coordinates robotic assembly lines by integrating vision sensors, PLCs, and HMIs. Its high-response frequency (500 Hz) supports real-time adjustments in automotive welding and electronics packaging processes1214.

The IMRIO02 coordinates robotic assembly lines by integrating vision sensors, PLCs, and HMIs. Its high-response frequency (500 Hz) supports real-time adjustments in automotive welding and electronics packaging processes1214.

Process Industries:

For chemical and pharmaceutical plants, the module regulates reactor temperature profiles and batch processing sequences by converting signals from IMFEC12 analog input modules into control commands. Its programmable logic capabilities (IEC 61131-3 languages) enable custom algorithms for process optimization721.

For chemical and pharmaceutical plants, the module regulates reactor temperature profiles and batch processing sequences by converting signals from IMFEC12 analog input modules into control commands. Its programmable logic capabilities (IEC 61131-3 languages) enable custom algorithms for process optimization721.

Related Products

- ABB IMRI01: Remote I/O Master Module that pairs with the IMRIO02 to form a complete distributed I/O system.

- ABB IMMFP12: Multifunctional Processor Module that communicates with the IMRIO02 via InfiNet protocol for centralized control.

- ABB IMFEC12: High-level analog input module for precise signal acquisition in process monitoring.

- ABB IMDS014: 16-channel digital output module for discrete control in automation systems.

- ABB IMHSS03: Hydraulic servo slave module for turbine and heavy machinery control.

Installation and Maintenance

Installation Preparations:

- Mount the IMRIO02 on a DIN rail using torque screws (1.5–2.5 N·m) to secure against vibration.

- Connect shielded cables to the NTMP01 termination unit for power and communication.

- Configure the module’s slave address (DIP switches) and I/O card types using Control Builder M software1421.

Maintenance Recommendations:

- Regularly inspect LED indicators for power, communication, and fault status.

- Clean vents with compressed air every six months to prevent dust accumulation.

- Perform annual calibration checks for analog inputs/outputs using ABB’s diagnostic tools.

- Replace electrolytic capacitors every 5–7 years to ensure long-term reliability1421.

Product Guarantee

ABB warrants the IMRIO02 against defects in materials and workmanship for 1 year from purchase. This includes free repair or replacement of faulty components, supported by ABB’s global network of certified technicians. Customers receive 24/7 technical support for installation, configuration, and troubleshooting, with remote assistance available via secure VPN. ABB’s Extended Service Agreement offers proactive maintenance, firmware updates, and priority spare parts delivery for up to 5 years, ensuring continuous system reliability. The IMRIO02 complies with CE, UL, ROHS, and Class I, Div 2 standards, providing peace of mind in safety-critical applications1421.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com