Description

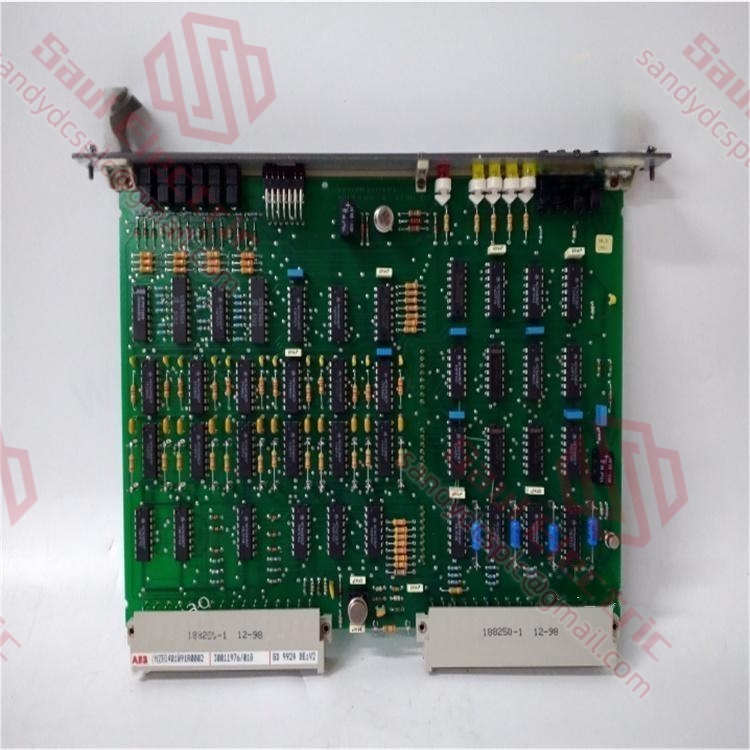

ABB GD9924BE V2 HIEE401091R0002 Multi-function Controller Product Description

Product Overview

In industrial automation scenarios that demand integration, response speed, compatibility and scalability, a versatile core controller can always simplify the architecture of the entire system. The ABB GD9924BE V2 HIEE401091R0002 is a high-performance multi-function control module built for harsh industrial environments, and a core component in ABB’s advanced industrial automation control portfolio.

Equipped with cutting-edge digital signal processing technology and customized control algorithms, this module takes charge of core tasks such as field data acquisition, logic operation and multi-channel signal processing. It can independently implement full-automatic control for small and medium-sized equipment, and also serve as a backup unit for PLC and DCS systems to complete real-time regulation, signal analysis and global system monitoring. Actually, compact installation space is a common pain point in industrial sites, and this controller, with a mere 100×100×50mm compact size, integrates full-range I/O interfaces for digital and analog signals, allowing direct connection to various field sensors and actuators without extra adapter boards.

It supports mainstream industrial communication protocols including Modbus RTU, Modbus TCP and EtherNet/IP, enabling efficient data interaction with third-party controllers, SCADA systems and human-machine interface devices, and realizing seamless integration across devices and systems. It adapts stably to applications ranging from logic control for simple stand-alone equipment to complex factory-level automation networking, making it an optimal core component for building modern industrial automation solutions.

Technical Specifications Table

| Parameter Name | Parameter Value |

|---|---|

| Product Model | GD9924BE V2 HIEE401091R0002 |

| Manufacturer | ABB |

| Product Type | Multi-function Controller Module |

| Power Supply | 90-264 VAC, 50/60 Hz |

| Power Consumption | 100W |

| Operating Temperature | -20°C to 60°C (-4°F to 140°F) |

| Dimensions | 100 x 100 x 50 mm (3.9 x 3.9 x 1.9 inches) |

| Protection Rating | IP20 |

| Communication Protocols | Modbus RTU, Modbus TCP, EtherNet/IP |

| Programming Support | CoDeSys, IEC 61131-3 standard |

| Output Frequency | 30kHz |

Key Features and Advantages

High performance and stability stand as the core competitiveness of this controller. The optimized hardware architecture paired with dedicated control algorithms maintains continuous and stable operation and outputs precise control commands even under high-load and multi-task complex working conditions. For process industries with strict requirements, isn’t this the most essential demand? The modular design endows it with excellent flexibility and scalability, allowing engineers to customize function configurations based on on-site process needs without being restricted by fixed architectures during debugging.

In terms of communication adaptation, it covers the most commonly used protocols in modern industrial sites, and rarely encounters compatibility barriers when networking with PLCs, industrial computers, frequency converters and robots of different brands, greatly reducing the difficulty and cost of system integration. The module features built-in full-range protection mechanisms including overload, short circuit and under-voltage protection, guarding the power supply system and external devices throughout and cutting the risk of downtime due to faults at the source.

The programming part also fits the usage habits of on-site engineers. Supporting the CoDeSys development environment and IEC 61131-3 standard, engineers can quickly complete program development and debugging with familiar tools and shorten the project implementation cycle. The whole machine adopts industrial-grade high-spec components, and the robust structure can resist conventional vibration and dust interference, while the wide temperature range of -20°C to 60°C adapts to most industrial site environments. Coupled with the ultra-wide power input range of 90-264VAC, it can be directly used in plants with different power supply qualities in different regions, and the compact size allows it to be embedded in various narrow control cabinet spaces.

Application Areas

This multi-function controller covers almost all types of industrial automation scenarios. In conventional industrial control, it can implement closed-loop control for analog processes, real-time instrument monitoring and factory-wide automation system scheduling, precisely controlling the process parameters of the entire production flow. Process industries such as chemicals, petroleum, building materials, rubber, power generation, environmental protection and water treatment can rely on it for continuous monitoring and automatic adjustment of key processes to maintain production stability.

It completes multi-device collaborative control and action logic scheduling for automated production lines in heavy industries including metallurgy, steel, automotive manufacturing and aerospace; the food and beverage industry can realize production process automation and online quality monitoring through it. In addition, it can act as the core control unit for conventional machinery control, intelligent networked PLC control, automatic test systems and distributed data acquisition systems.

Its adaptation advantages are more prominent in old system renovation and non-standard customization projects. Whether it is whole-network system integration, non-standard equipment customization, intelligent upgrade of production lines, or replacement of old electrical control equipment, it can provide flexible and reliable control solutions. Its powerful protocol compatibility allows easy access to existing automation networks, linkage and communication with programmable devices of different brands, helping enterprises realize centralized management of production data.

Related Products

ABB products in the same system that can form a complete control, expansion, protection and communication solution with GD9924BE V2 include: PM851 high-performance PLC controller in the same product family for higher-level control tasks; DX561 digital input module and AX561 analog input module to flexibly expand signal acquisition points; RET615 protective relay for power system protection applications to collaboratively implement power supply safety protection; TB820V2 communication interface module to add extra communication channels; DSQC series robot control products (including DSQC236T, DSQC266G, etc.) for coordinated control in robotic automation systems; UFC760BE series drive products to form a complete drive control system with this controller.

Installation and Maintenance

Please read the safety-related information and technical documents carefully before installation. Operators and installers must have experience in the assembly and maintenance of industrial electrical control equipment and complete ABB-specific professional training, which is the basis for safe equipment installation and long-term stable operation. Check the installation environment in advance to ensure that the temperature, humidity and dust conditions meet the application requirements of -20°C to 60°C and IP20 protection rating, and confirm that the power supply voltage falls within the range of 90-264VAC to avoid early failures caused by mismatched environment and power supply.

Daily maintenance must be performed by professionally trained personnel in strict accordance with safe operation procedures. Regularly check the operating status and indicator alarm information of the controller, keep the machine body and control cabinet well-ventilated for heat dissipation, and clean surface dust in time to prevent heat accumulation from affecting performance. Always disconnect power before any maintenance operation to eliminate electric shock risks. Unauthorized disassembly and debugging by non-professionals may not only damage the equipment but also cause personal safety hazards. For complex program and hardware faults, you can directly contact ABB’s official technical team for professional support.

Product Guarantee

ABB has established a full-process factory inspection system for GD9924BE V2 HIEE401091R0002. Each unit passes strict performance and environmental tests, complying with international industrial electrical safety standards, and can maintain long-term reliable operation even in harsh industrial environments. Products purchased through official channels enjoy a 1-year official warranty. For original factory quality problems, feedback can be submitted and after-sales processing completed within 7 days.

ABB and its authorized suppliers provide full-process technical support, including professional services such as model selection advice, program debugging guidance and fault location solutions. It should be noted that damage caused by human or illegal operations such as power failure, burning, physical damage and tampering with the tamper seal is not covered by the warranty. Relying on ABB’s global service network, users can obtain timely technical response and spare parts supply, fully exert the performance advantages of this controller and ensure the long-term stable operation of automation systems.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com