Description

Product Overview

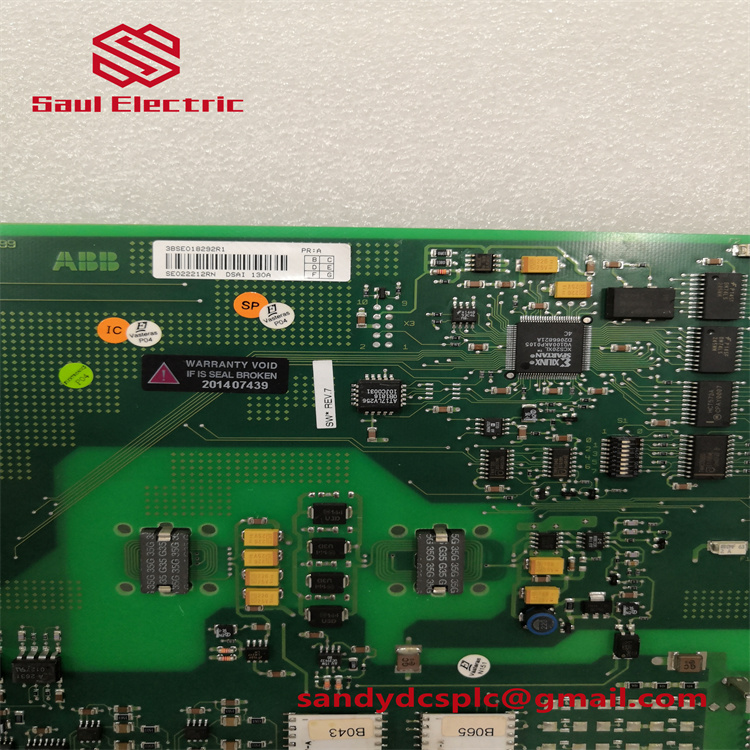

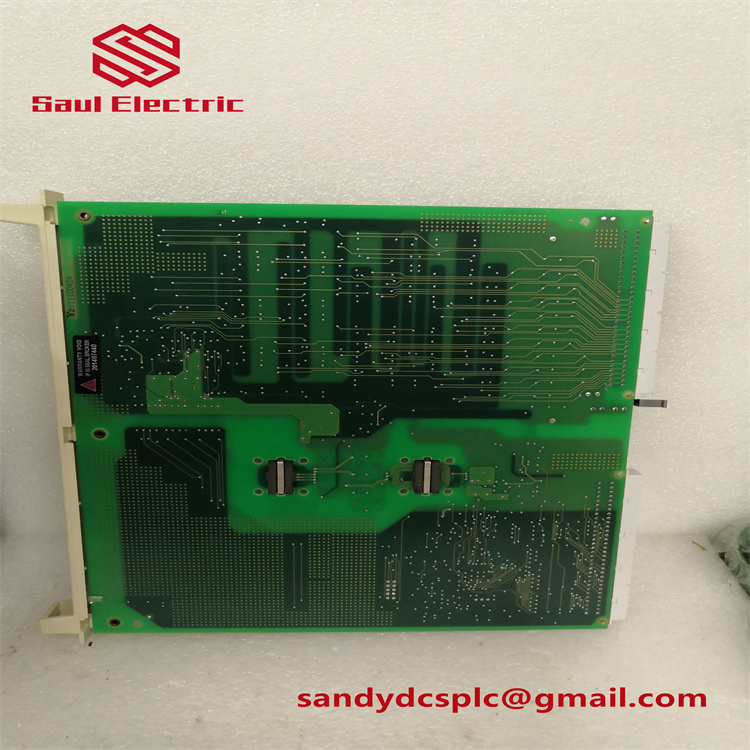

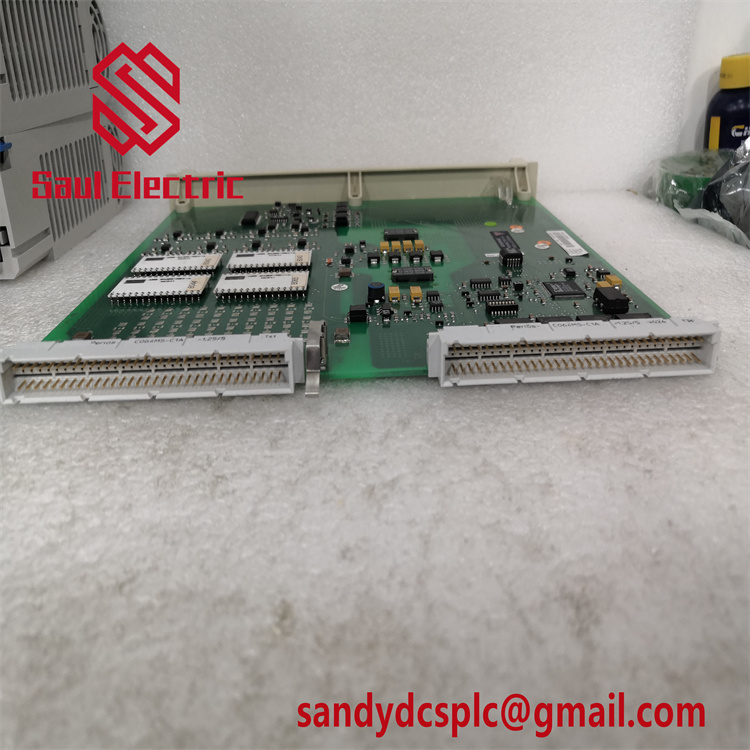

The ABB DSBB175 is a high-performance bus backplane module designed for industrial automation systems, specifically tailored to support seamless communication and module integration within distributed control systems (DCS). As part of ABB’s advanced automation portfolio, the DSBB175 serves as a critical hardware component that enables efficient data transfer and power distribution between multiple control modules. This module is engineered to withstand rigorous industrial environments, ensuring reliable operation in demanding applications. The DSBB175 features a robust design with standardized interfaces, allowing for easy integration into existing systems while supporting high-speed data transmission protocols. Its role as a backplane ensures stable connectivity and signal integrity, making it an essential component for maintaining system reliability and performance in complex automation setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DSBB175 |

| Manufacturer | ABB |

| Product Type | Bus Backplane Module |

| Electrical Supply | 24 V DC ±10% |

| Power Consumption | ≤15 W |

| Communication Protocol | Supports Modbus, Profibus, Ethernet |

| Dimensions (L×W×H) | 240 mm × 180 mm × 80 mm |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Resistance | 5% to 95% non-condensing |

| Installation Method | Rack-mounted, DIN rail compatible |

| Weight | Approximately 1.2 kg |

Main Features and Advantages

The ABB DSBB175 stands out for its exceptional reliability and adaptability in industrial automation setups. It offers a modular design that facilitates straightforward installation and maintenance, reducing downtime and enhancing system flexibility. The module’s high-speed data processing capability ensures minimal latency, enabling real-time communication between control modules, which is crucial for time-sensitive applications. Its robust construction and wide operating temperature range make it suitable for harsh industrial environments, from manufacturing plants to energy facilities. The DSBB175 also supports multiple communication protocols, allowing seamless integration with diverse system architectures and ensuring compatibility with existing infrastructure. Additionally, the module’s standardized interface design simplifies inventory management and replacement, as it aligns with ABB’s broader range of automation components, promoting long-term system consistency and support.

Application Areas

The ABB DSBB175 is ideally suited for various industrial sectors requiring reliable distributed control systems. In power generation, it supports the integration of control modules for turbine management and power distribution networks. In the chemical and petrochemical industries, the module ensures stable communication between process control units, enabling precise monitoring and adjustment of production parameters. It is also widely used in manufacturing automation, where it facilitates coordination between robotic systems, PLCs, and human-machine interfaces (HMIs). Furthermore, the DSBB175 finds applications in water treatment plants, where it helps manage complex control loops for filtration and distribution systems. Its ability to withstand harsh conditions makes it suitable for outdoor installations and environments with high vibrations or temperature fluctuations, ensuring consistent performance across diverse operational scenarios.

Related Products

- DIS0006 ABB – The Power Contractor

- ABB DLM01 Freelance 2000 P 37421-4-0369-652

- ABB DLM01 Freelance 2000 P 37421-4-0369-652

- ABB DLM02 Link Module 100% Original and Genuine

- DI840 Digital Input 24V S/R 16 ch ABB 3BSE020836R1

Installation and Maintenance

Installation 前准备: Ensure the installation environment meets the DSBB175’s environmental specifications, including temperature and humidity ranges. Prepare the mounting rack or DIN rail, ensuring it is securely fastened. Verify the power supply matches the module’s requirements (24 V DC) and gather all necessary tools for wiring and connection.

Maintenance 建议: Regularly inspect the DSBB175 for physical damage or loose connections, especially in high-vibration environments. Clean the module periodically to remove dust and debris that could affect performance. Monitor power supply voltage and temperature levels using the system’s diagnostic tools to ensure optimal operation. Replace any faulty components immediately to prevent cascading system issues, and refer to ABB’s official documentation for detailed troubleshooting guides.

Product Guarantee

ABB stands behind the DSBB175 with a comprehensive 1-year warranty, ensuring coverage against manufacturing defects and performance issues. The company offers dedicated technical support and maintenance services to assist customers in optimizing system performance and resolving any operational challenges. ABB’s global service network ensures prompt response times and access to genuine spare parts, guaranteeing long-term reliability and support for the DSBB175 throughout its lifecycle.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com