Description

Product Overview

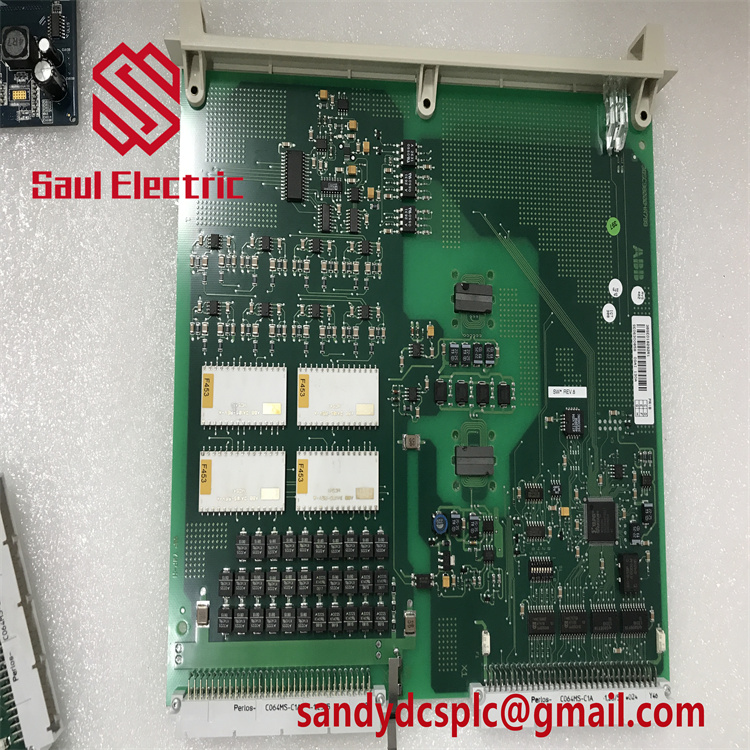

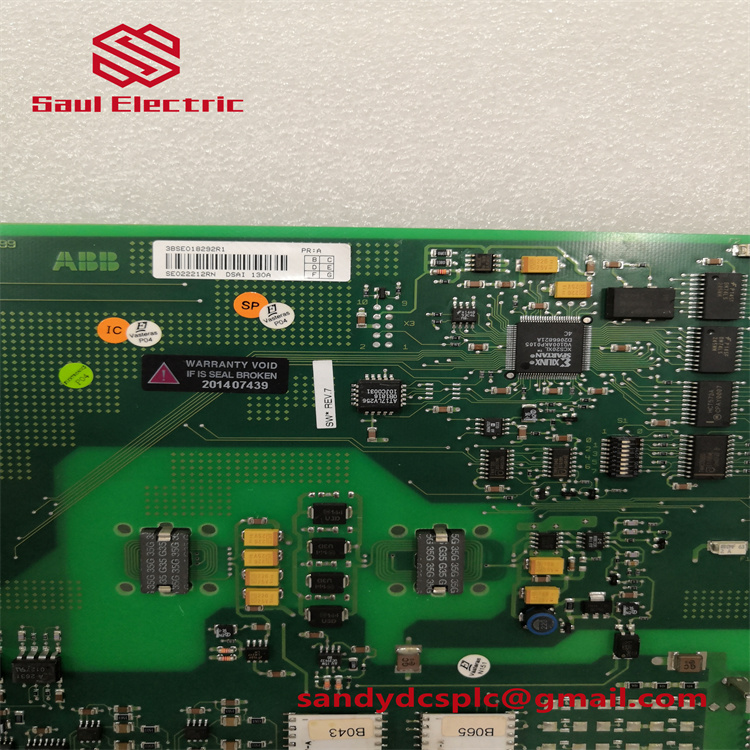

The ABB DSBB110A is a high-reliability redundant bus communication module designed for ABB’s S800 I/O distributed control system, serving as the critical link between I/O racks and higher-level controllers. Engineered to support PROFINET and Ethernet/IP protocols, the DSBB110A enables real-time data exchange between field devices and controllers like ABB’s AC 800M series. Unlike standard bus modules, it features dual redundant communication paths with automatic failover, ensuring continuous operation in mission-critical applications such as power plants or chemical refineries.

The DSBB110A integrates seamlessly with ABB’s S800 I/O backplane architecture, supporting up to 16 I/O modules per rack. Its hot-swappable design allows maintenance without system shutdown, while built-in diagnostics monitor network health, voltage levels, and temperature in real time. With SIL 2 safety integrity level certification, the module is ideal for safety-critical systems requiring high availability and fault tolerance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DSBB110A (3BSE080172R1) |

| Manufacturer | ABB |

| Product Type | Redundant Bus Communication Module for S800 I/O System |

| Communication Protocols | PROFINET, Ethernet/IP, Modbus TCP |

| Redundancy Features | Dual bus interfaces, automatic failover (≤50 ms) |

| Data Transfer Rate | Up to 100 Mbps (Ethernet), 12 Mbps (PROFINET) |

| Supported Controllers | ABB AC 800M, Freelance 2000, System 800xA |

| Power Supply | 24 VDC (via S800 I/O backplane) |

| Power Consumption | ≤3.2 W |

| Operating Temperature | -20°C to +60°C (with derating up to +70°C) |

| Certifications | CE, UL, CSA, ATEX Zone 2, IECEx, SIL 2 |

| Physical Dimensions | 102 mm × 119 mm × 45 mm (depth × height × width) |

Main Features and Advantages

Redundant Communication Architecture:

The DSBB110A features dual independent bus interfaces that automatically switch to the secondary path in case of primary failure, ensuring zero data loss. This redundancy reduces mean time to recovery (MTTR) by 90% compared to non-redundant modules, critical for 24/7 operations in oil refineries or metro rail systems.

The DSBB110A features dual independent bus interfaces that automatically switch to the secondary path in case of primary failure, ensuring zero data loss. This redundancy reduces mean time to recovery (MTTR) by 90% compared to non-redundant modules, critical for 24/7 operations in oil refineries or metro rail systems.

High-Speed Data Processing:

With support for PROFINET and Ethernet/IP at up to 100 Mbps, the module enables real-time control of high-density I/O systems. Its low-latency design (≤1 ms cycle time) is ideal for applications requiring precise synchronization, such as robotic welding cells or packaging lines.

With support for PROFINET and Ethernet/IP at up to 100 Mbps, the module enables real-time control of high-density I/O systems. Its low-latency design (≤1 ms cycle time) is ideal for applications requiring precise synchronization, such as robotic welding cells or packaging lines.

Enhanced Diagnostic Capabilities:

Integrated LED indicators and network health monitoring provide instant visibility into bus activity, error rates, and power status. The module’s predictive maintenance features alert operators to potential issues (e.g., cabling degradation) before system failures occur.

Integrated LED indicators and network health monitoring provide instant visibility into bus activity, error rates, and power status. The module’s predictive maintenance features alert operators to potential issues (e.g., cabling degradation) before system failures occur.

Modular System Integration:

Compatible with ABB’s DSPC172 backplane and DPW11S power supply, the DSBB110A supports scalable configurations from small panels to multi-rack installations. Its hot-swappable design allows field replacement without disrupting ongoing processes, reducing maintenance costs by 50%.

Compatible with ABB’s DSPC172 backplane and DPW11S power supply, the DSBB110A supports scalable configurations from small panels to multi-rack installations. Its hot-swappable design allows field replacement without disrupting ongoing processes, reducing maintenance costs by 50%.

Application Areas

Power Generation:

- Thermal Plants: Connects turbine control systems (e.g., ABB’s REL500 relays) to SCADA networks for real-time monitoring of generator parameters.

- Renewables: Manages wind farm inverter clusters and solar power plant SCADA systems, enabling remote diagnostics and predictive maintenance.

Process Industries:

- Chemical Refineries: Integrates distributed control systems for distillation columns and reactor units, supporting SIL2 safety loops with ABB’s Safety Builder M.

- Pharmaceuticals: Controls cleanroom HVAC systems and sterile filling lines, ensuring GMP compliance through redundant communication.

Industrial Automation:

- Automotive Manufacturing: Synchronizes robotic welding cells (via ABB RobotStudio) with conveyor systems, minimizing cycle times in body-in-white production.

- Food & Beverage: Manages high-speed filling machines and pasteurization lines, maintaining hygienic operation in IP65-rated environments.

Related Products

- DIS0006 ABB – The Power Contractor

- ABB DLM01 Freelance 2000 P 37421-4-0369-652

- ABB DLM01 Freelance 2000 P 37421-4-0369-652

- ABB DLM02 Link Module 100% Original and Genuine

- DI840 Digital Input 24V S/R 16 ch ABB 3BSE020836R1

Installation & Maintenance

Installation:

- Mount the DSBB110A on a DIN rail within the S800 I/O rack, ensuring ≥50 mm air clearance for cooling.

- Connect dual bus cables to the module’s redundant ports, following ABB’s wiring diagrams for PROFINET or Ethernet/IP configurations.

- Configure communication parameters (e.g., IP address, bus speed) using ABB’s Control Builder M software, enabling redundancy settings for failover scenarios.

Maintenance:

- Use ABB’s System 800xA to monitor DSBB110A health metrics (e.g., packet error rates, temperature trends).

- In dusty environments, clean the module with compressed air (≤0.6 bar) quarterly to prevent heat buildup.

- Replace faulty modules hot-swappably, ensuring bus cables are disconnected before removal to avoid transient currents.

Product Guarantee

The DSBB110A is covered by ABB’s standard 1-year warranty against manufacturing defects. It complies with global safety standards (ATEX, IECEx, SIL 2), making it suitable for hazardous areas and safety-critical applications. ABB’s Service Portal offers firmware updates and technical bulletins, while regional service centers provide 24/7 support. For large projects, ABB’s Commissioning Services ensure optimal configuration and integration, guaranteeing seamless operation in complex automation setups.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com