Description

Product Overview

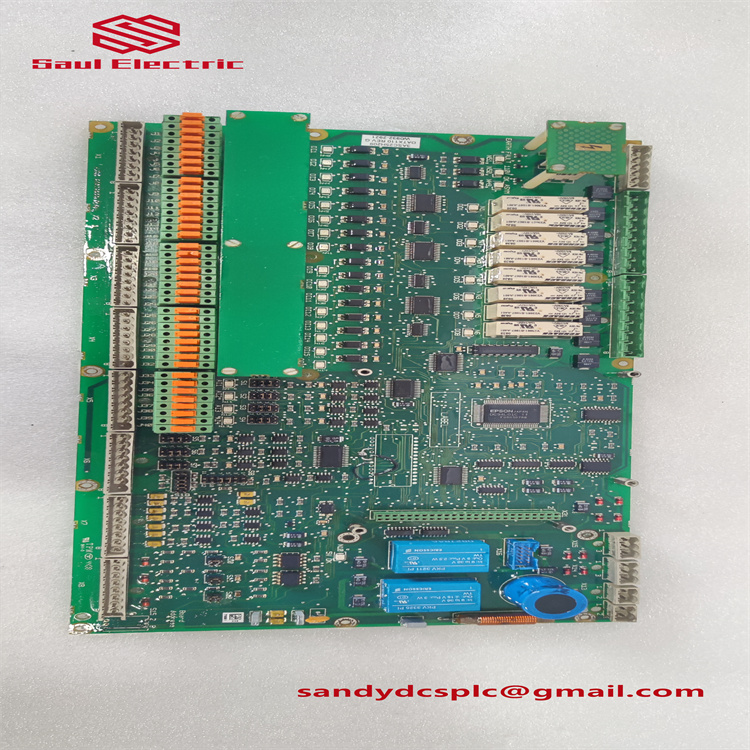

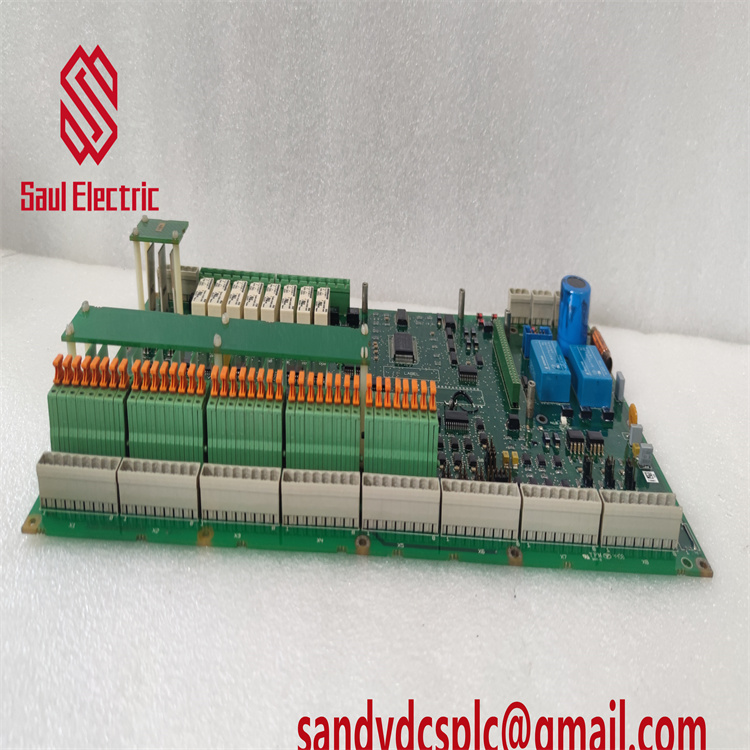

The ABB DASD001 is a high-performance industrial communication interface module designed for legacy automation systems, providing seamless integration between ABB controllers and third-party devices. Engineered with ABB’s precision engineering, the DASD001 serves as a critical bridge for protocol conversion, signal routing, and data exchange in manufacturing, energy, and process industries. As part of ABB’s DASD series, this module is optimized for retrofitting older systems while maintaining compatibility with modern industrial networks .

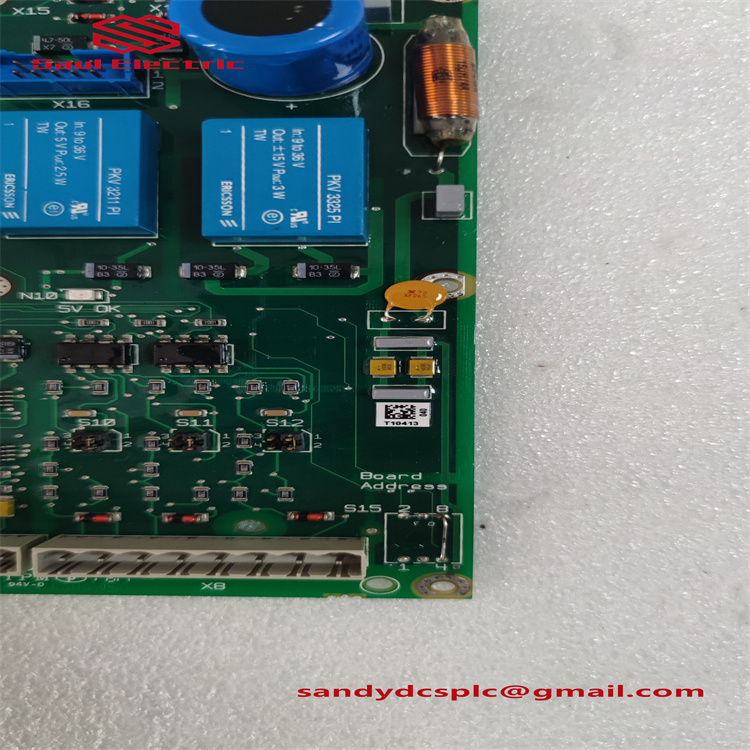

Key functionalities include multi-protocol support (e.g., Modbus RTU, Profibus DP) and analog/digital I/O connectivity, enabling real-time data transfer between ABB drives (e.g., DARA 2000) and PLCs (e.g., AC500). Its compact DIN rail-mountable design (112.5 mm width × 234 mm depth) ensures space efficiency in control cabinets, while the 24 VDC power supply guarantees stable operation in harsh environments. The DASD001 also features hot-swappable capabilities, allowing maintenance without system downtime—a crucial advantage for continuous industrial operations .

In industrial automation, the DASD001 plays a pivotal role in modernizing legacy systems by enabling interoperability with newer Ethernet-based devices. For example, it can convert ABB’s proprietary protocols to Modbus TCP for integration with SCADA systems, enhancing remote monitoring and predictive maintenance capabilities. This versatility makes it an ideal solution for upgrading aging infrastructure while minimizing hardware replacement costs .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DASD001 |

| Manufacturer | ABB |

| Product Type | Industrial Communication Interface Module |

| Communication Protocols | Modbus RTU, Profibus DP, DeviceNet (compatibility varies by firmware version) |

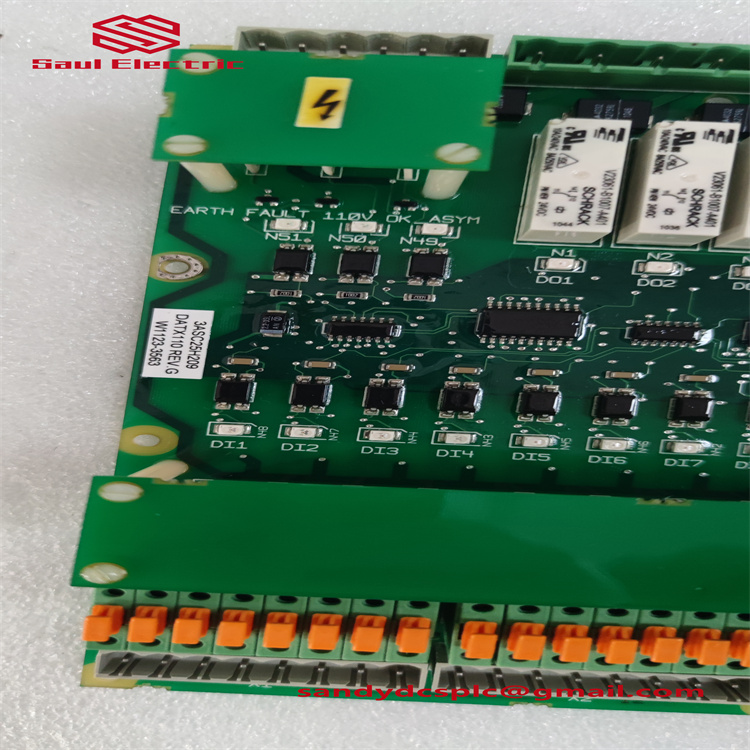

| Interface | 1× RS485, 1× Profibus DP, 2× digital I/O, 2× analog I/O |

| Power Supply | 24 VDC ±15% |

| Current Consumption | ≤500 mA |

| Data Rate | Up to 12 Mbps (Profibus DP) |

| Operating Temperature | -20°C to +60°C |

| Physical Dimensions | 112.5 mm (width) × 234 mm (depth) × 80 mm (height) |

| Weight | 0.8 kg |

| Certifications | CE, EN 61000-6-4 (EMC immunity), EN 61000-6-2 (EMC emission) |

Main Features and Advantages

Protocol Flexibility: The DASD001 supports multiple industrial protocols, acting as a translator between ABB’s legacy systems and modern Ethernet-based networks. This allows users to integrate older drives (e.g., DARA 2000) with newer HMIs or cloud platforms without replacing entire control systems .

Rugged Design: Built to withstand IP20-rated environmental conditions, the module resists dust, vibrations, and electromagnetic interference, ensuring reliability in factory floors or outdoor installations. Its hot-swappable design further reduces downtime during maintenance .

Scalable Connectivity: With configurable I/O channels (2× digital, 2× analog) and dual communication ports, the DASD001 adapts to diverse automation setups. It can interface with sensors, actuators, and PLCs, enabling centralized control in complex manufacturing lines .

Cost-Effective Modernization: By extending the lifespan of legacy equipment, the DASD001 minimizes capital expenditure while delivering advanced monitoring capabilities. For example, it can connect ABB’s REF615 protection relays to cloud-based energy management systems, optimizing power grid efficiency .

Diagnostic Efficiency: LED indicators provide real-time status updates for power, communication links, and protocol errors, simplifying troubleshooting. ABB’s DriveWindow LT software further enhances configuration and diagnostics, reducing commissioning time .

Application Areas

Industrial Automation:

- Manufacturing: Integrates ABB AC500 PLCs with Modbus RTU-compatible sensors in automotive assembly lines, enabling predictive maintenance and process optimization.

- Packaging: Bridges DARA 2000 drives with Profibus DP-based HMIs for real-time monitoring of filling and labeling machines .

Energy Management:

- Power Generation: Connects ABB REF615 relays to SCADA systems via Modbus RTU, facilitating remote monitoring of power grids and renewable energy installations.

- Oil & Gas: Enables DeviceNet communication between ABB ACS550 drives and distributed control systems (DCS) in offshore platforms .

Building Automation:

- HVAC Systems: Interfaces ABB’s i-bus® KNX system with third-party controllers for energy-efficient climate control in commercial buildings.

- Facility Management: Integrates legacy ABB Freelance 2000 DCS with modern IoT gateways to monitor lighting and security systems .

Related Products

- ABB DASD146 (3ASC25H270): A predecessor connection board for ABB drives, offering similar I/O capabilities but limited protocol support.

- ABB DSQC639 (3HAC025097-001): A modern communication module for ABB robots, supporting Ethernet/IP and Profinet.

- ABB DSQC652: An I/O module for IRC5 controllers, complementing the DASD001 in robotic automation setups.

- ABB ACS880 Drives: Next-generation variable-speed drives compatible with the DASD001 via Modbus RTU or Profibus DP.

- ABB AC500 PLC: A modular PLC platform that pairs with the DASD001 for distributed control in manufacturing .

Installation and Maintenance

Installation:

- Mount the DASD001 on a DIN rail using standard clips, ensuring 20 mm clearance for heat dissipation.

- Connect 24 VDC power and RS485/Profibus DP cables. Use shielded cables to minimize interference.

- Configure protocols and I/O settings via ABB’s DriveWindow LT software or web-based interface. Verify compatibility with existing system firmware .

Maintenance:

- Regularly inspect LED indicators for communication errors. Replace faulty modules using hot-swap functionality to avoid downtime.

- Clean the module’s surface with a dry cloth and check terminal connections in high-vibration environments.

- Update firmware annually to support new protocols and security patches. ABB’s Ability™ Remote Support offers remote diagnostics and troubleshooting .

Product Guarantee

ABB provides a 1-year warranty for the DASD001, covering defects in materials and workmanship. The module meets CE and EN 61000 standards for EMC and environmental reliability. ABB’s global service network offers 24/7 technical support, spare parts, and training to ensure optimal performance. For critical applications, ABB’s Ability™ Condition Monitoring can predict potential failures, reducing unplanned downtime .

By combining rugged durability with protocol flexibility, the ABB DASD001 delivers a future-proof solution for retrofitting legacy automation systems, ensuring seamless integration with modern industrial networks.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com