Description

Product Overview

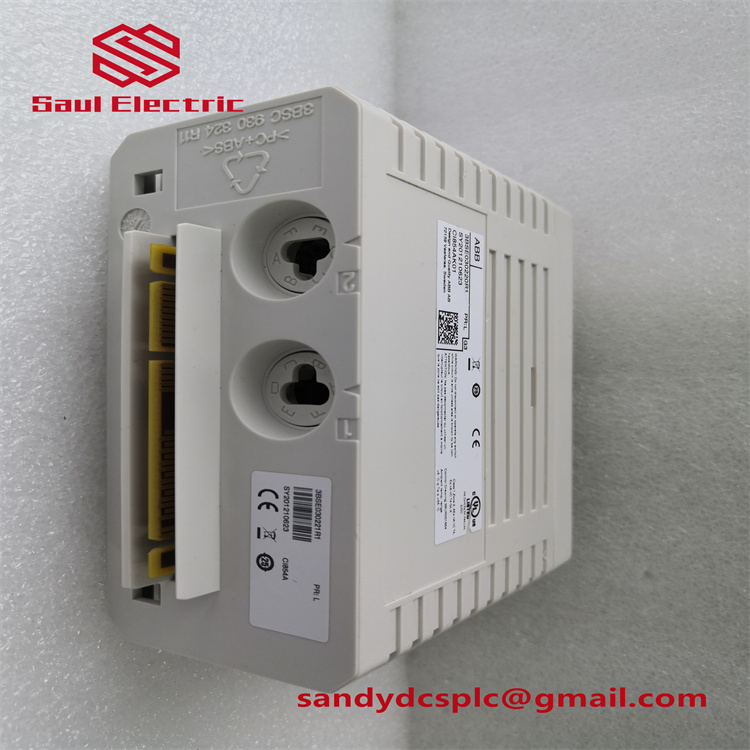

The ABB CI857K01 is a high – performance communication interface module, an integral part of the ABB AC 800M controller family. It plays a pivotal role in enabling seamless and efficient data exchange between the AC 800M controllers and a wide array of field devices. This module is designed to support ABB’s INSUM (Intelligent Substation Unit) technology, which is crucial for modern industrial automation setups.

The ABB CI857K01 is a high – performance communication interface module, an integral part of the ABB AC 800M controller family. It plays a pivotal role in enabling seamless and efficient data exchange between the AC 800M controllers and a wide array of field devices. This module is designed to support ABB’s INSUM (Intelligent Substation Unit) technology, which is crucial for modern industrial automation setups.

The CI857K01 allows for higher functionality integration within switchgear, facilitating complex control strategies. It supports multi – drop configurations, enabling connection to multiple devices on a single communication line, which is highly beneficial for optimizing system layout and reducing wiring complexity. With features like time distribution and time stamping, it ensures accurate synchronization of operations across distributed systems. Leveraging standard Ethernet technology, it can achieve longer communication distances, making it suitable for large – scale industrial plants. The module is powered by the processor unit via the CEX – bus, eliminating the need for an additional external power source, thus simplifying the installation process.

In terms of network capabilities, the CI857K01 supports a variety of communication protocols. It can handle TCP/IP, UDP, Modbus TCP, and is compliant with IEC 61850, which is widely used in power distribution and substation automation. This multi – protocol support makes it extremely versatile and capable of integrating with diverse legacy and modern systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | CI857K01 |

| Manufacturer | ABB |

| Product Type | Communication Interface Module |

| Supported Ethernet Standards | 10/100/1000 Base – TX |

| Number of Ethernet Ports | 2 |

| Auto – negotiation and Auto – MDIX Support | Yes |

| Redundancy Options | Hot – swappable |

| Supported Protocols | TCP/IP, UDP, Modbus TCP, IEC 61850 |

| Operating Temperature | – 40 °C to + 70 °C |

| Storage Temperature | – 40 °C to + 85 °C |

| Certifications | CE, UL, EAC |

| Dimensions (Height x Width x Depth) | 185 mm x 59 mm x 127.5 mm |

| Weight (including base) | 700 g (1.5 lbs) |

| Maximum Units on CEX Bus | 6 |

| Connector Type | RJ – 45 female (8 – pin) |

| 24V Consumption (Typ.) | 150 mA |

Main Features and Advantages

Multi – protocol Connectivity: The CI857K01 supports a rich set of protocols, such as TCP/IP, UDP, Modbus TCP, and IEC 61850. This enables it to communicate with a vast range of devices, from traditional industrial sensors and actuators to modern smart grid components. It eliminates the need for multiple specialized gateways, reducing both cost and complexity in system integration.

Multi – protocol Connectivity: The CI857K01 supports a rich set of protocols, such as TCP/IP, UDP, Modbus TCP, and IEC 61850. This enables it to communicate with a vast range of devices, from traditional industrial sensors and actuators to modern smart grid components. It eliminates the need for multiple specialized gateways, reducing both cost and complexity in system integration.

High – speed Ethernet: With support for 10/100/1000 Base – TX Ethernet standards and auto – negotiation capabilities, it ensures high – speed and reliable data transfer. The dual Ethernet ports also allow for redundant network connections, enhancing system uptime and reliability.

Hot – swap Capability: In case of a module failure, the hot – swap feature enables replacement without shutting down the entire system. This significantly reduces maintenance downtime, which is critical in industries where continuous operation is essential, such as power generation and manufacturing.

Scalability: In an AC 800M system, there can be up to 6 CI857K01 modules per AC 800M controller. Each CI857K01 can support up to 128 MCUs (or other INSUM devices), making it highly scalable for large – scale industrial automation projects.

Rugged Design: Built to withstand harsh industrial environments, the module can operate in temperatures ranging from – 40 °C to + 70 °C. Its IP20 protection class shields it from dust and other small particles, ensuring reliable performance over an extended period.

Application Areas

Power Generation and Distribution: In power plants, the CI857K01 is used to connect various substation components, such as intelligent electronic devices (IEDs), to the AC 800M controllers. It enables real – time monitoring and control of power distribution networks, ensuring grid stability and efficient energy management. For example, it can be used to synchronize the operation of circuit breakers, transformers, and power meters in a substation.

Power Generation and Distribution: In power plants, the CI857K01 is used to connect various substation components, such as intelligent electronic devices (IEDs), to the AC 800M controllers. It enables real – time monitoring and control of power distribution networks, ensuring grid stability and efficient energy management. For example, it can be used to synchronize the operation of circuit breakers, transformers, and power meters in a substation.

Manufacturing: In manufacturing plants, the module plays a crucial role in connecting industrial robots, programmable logic controllers (PLCs), and other automation equipment to the central control system. It enables seamless communication between different production line components, optimizing production processes. For instance, it can be used to coordinate the operation of conveyor belts, robotic arms, and quality inspection sensors in an automotive assembly line.

Water and Wastewater Treatment: In water treatment plants, the CI857K01 connects sensors and actuators that monitor and control water quality, flow rates, and chemical dosing systems. It allows for real – time data collection and control, ensuring efficient and reliable water treatment processes. For example, it can be used to regulate the opening and closing of valves based on the water quality data from sensors.

Oil and Gas: In the oil and gas industry, the module is used to connect wellhead sensors, pumps, and other field devices to the central control room. It enables remote monitoring and control of oil and gas production processes, enhancing safety and productivity. For instance, it can be used to monitor the pressure and flow rate of oil pipelines and adjust the operation of pumps accordingly.

Related Products

- AC 800M Controller: The central processing unit of the ABB 800xA system, which the CI857K01 module interfaces with. Different models of AC 800M controllers vary in processing power, memory, and SIL (Safety Integrity Level) ratings, but all are compatible with the CI857K01 for enhanced communication capabilities.

- CI853: A communication module from ABB that supports ComLi and Modbus RTU master/slave protocols. While the CI857K01 focuses on Ethernet – based and INSUM – related communication, the CI853 serves different protocol – specific needs in an industrial automation setup.

- PM864/PM866: Processor modules for the AC 800M system. When paired with the CI857K01, they can support a higher number of MCUs (up to 256) in the system, compared to other processor modules like PM861, which can support 128 MCUs in combination with the CI857K01.

- INSUM TCP/IP Gateway: Works in tandem with the CI857K01. Each CI857K01 can support up to 2 such gateways, and each gateway can handle a significant number of INSUM devices, expanding the overall communication capabilities of the system.

- S800 I/O Modules: These I/O modules can be integrated into the system using the communication infrastructure provided by the CI857K01. They are used for connecting various sensors and actuators in industrial processes, and the CI857K01 helps in transmitting data between these modules and the AC 800M controller.

Installation and Maintenance

Installation Preparation:

Before installing the CI857K01, ensure that the AC 800M controller system is powered off. Check the compatibility of the module with the existing controller version and the CEX – bus. The module should be installed in a location that meets the environmental requirements, such as temperature (- 40 °C to + 70 °C) and humidity (5 – 95% non – condensing). Mount the module securely on the DIN rail using the appropriate brackets. Connect the Ethernet cables to the RJ – 45 ports, ensuring proper cable routing to avoid interference. Once physically installed, power on the system and configure the module settings using ABB’s Control Builder M software. This includes setting the IP address, protocol preferences, and any redundancy options.

Installation Preparation:

Before installing the CI857K01, ensure that the AC 800M controller system is powered off. Check the compatibility of the module with the existing controller version and the CEX – bus. The module should be installed in a location that meets the environmental requirements, such as temperature (- 40 °C to + 70 °C) and humidity (5 – 95% non – condensing). Mount the module securely on the DIN rail using the appropriate brackets. Connect the Ethernet cables to the RJ – 45 ports, ensuring proper cable routing to avoid interference. Once physically installed, power on the system and configure the module settings using ABB’s Control Builder M software. This includes setting the IP address, protocol preferences, and any redundancy options.

Maintenance Recommendations:

Regularly monitor the module’s performance using the built – in diagnostic tools in the Control Builder M software. Check for any communication errors, abnormal power consumption, or overheating issues. Update the firmware of the CI857K01 regularly to benefit from the latest features, security patches, and performance improvements provided by ABB. In case of a module failure, utilize the hot – swap feature to replace the faulty module without disrupting system operations. Keep the module and its surrounding area clean to prevent dust accumulation, which could affect its performance. Periodically inspect the Ethernet cables for any signs of wear or damage.

Regularly monitor the module’s performance using the built – in diagnostic tools in the Control Builder M software. Check for any communication errors, abnormal power consumption, or overheating issues. Update the firmware of the CI857K01 regularly to benefit from the latest features, security patches, and performance improvements provided by ABB. In case of a module failure, utilize the hot – swap feature to replace the faulty module without disrupting system operations. Keep the module and its surrounding area clean to prevent dust accumulation, which could affect its performance. Periodically inspect the Ethernet cables for any signs of wear or damage.

Product Warranty

The ABB CI857K01 comes with a 1 – year warranty. ABB stands firmly behind the quality of this product, covering any manufacturing defects that may occur during this period. In the unlikely event of a problem, ABB’s global network of authorized service centers is ready to provide support. Our technical experts are available 24/7 to offer remote diagnostics and guidance. If a replacement is necessary, ABB ensures a prompt delivery of a new module, minimizing downtime for your industrial operations. We are committed to ensuring that your investment in the CI857K01 remains a reliable and efficient part of your automation system.

The ABB CI857K01 comes with a 1 – year warranty. ABB stands firmly behind the quality of this product, covering any manufacturing defects that may occur during this period. In the unlikely event of a problem, ABB’s global network of authorized service centers is ready to provide support. Our technical experts are available 24/7 to offer remote diagnostics and guidance. If a replacement is necessary, ABB ensures a prompt delivery of a new module, minimizing downtime for your industrial operations. We are committed to ensuring that your investment in the CI857K01 remains a reliable and efficient part of your automation system.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com