Description

Product Overview

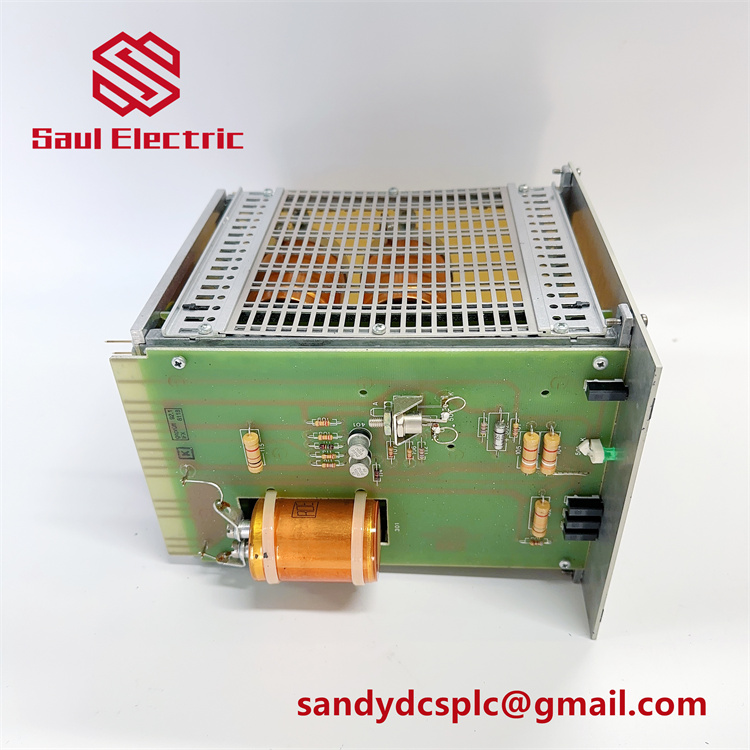

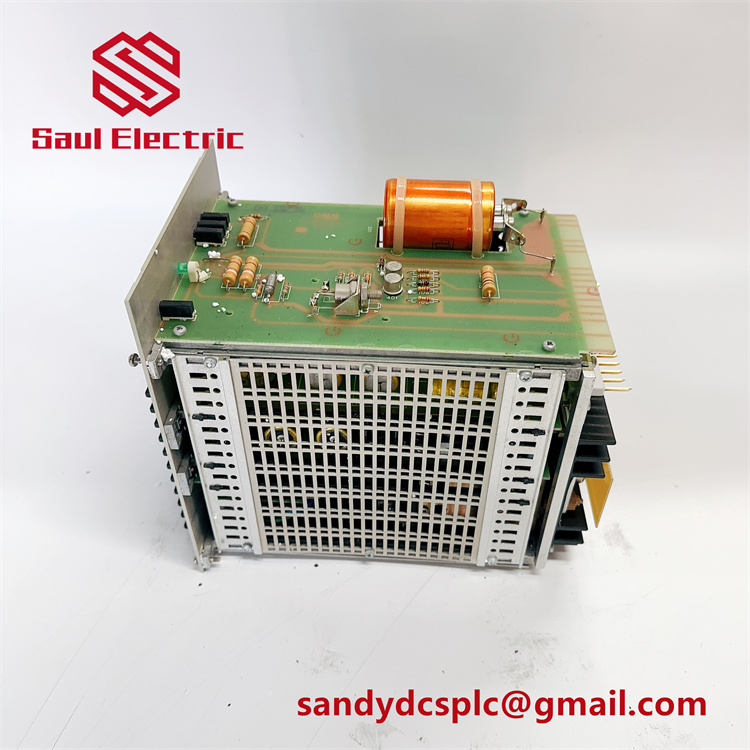

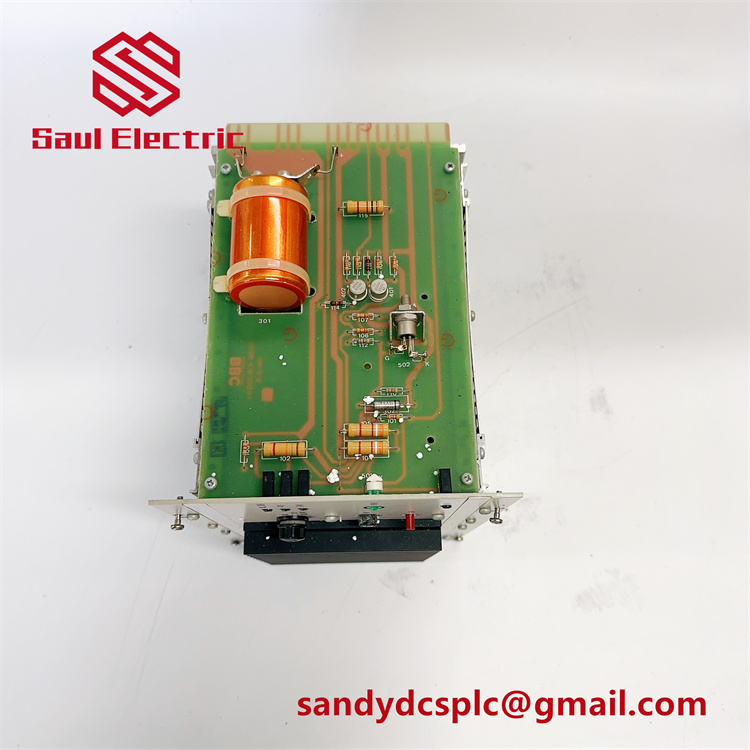

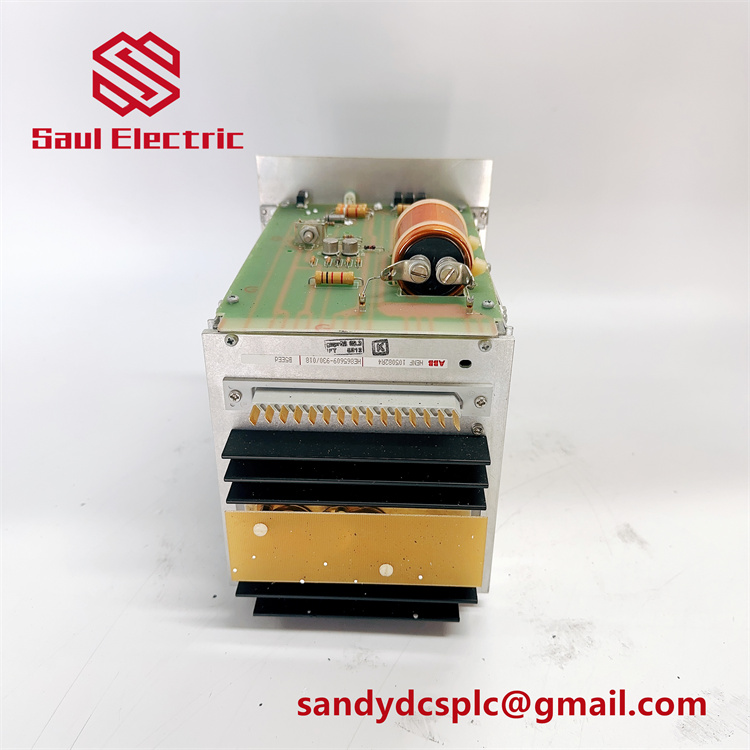

The ABB B5EEd HENF105082R4 is a high-performance electronic motor protection relay engineered for advanced monitoring and control of three-phase induction motors in industrial automation systems. As part of ABB’s Emax 2 series, this relay integrates seamlessly with motor control centers (MCCs) and distributed control systems (DCS), providing comprehensive protection against overload, phase imbalance, thermal stress, and voltage fluctuations. Designed for critical applications in manufacturing, energy, and water treatment, the ABB B5EEd HENF105082R4 combines precision sensing with intelligent diagnostics to minimize downtime and optimize motor efficiency .

Featuring programmable trip settings (0.1–1000% of motor rated current) and adaptive thermal memory, the relay prevents premature motor restarting and reduces mechanical wear. Its dual-channel communication supports both Modbus RTU and Ethernet/IP protocols, enabling real-time data exchange with PLCs, HMIs, and cloud-based monitoring platforms. The IP20-rated enclosure and -40°C to +70°C operating temperature range ensure reliability in harsh industrial environments, while ATEX and UL certifications guarantee compliance with global safety standards .

Key innovations include predictive fault detection for incipient winding failures and energy consumption tracking for operational optimization. The graphical LCD interface displays real-time parameters like current, voltage, and power factor, while status LEDs provide instant system health feedback. By combining protection, monitoring, and connectivity, the ABB B5EEd HENF105082R4 delivers a 30% reduction in maintenance costs compared to traditional thermal relays, making it a cornerstone of smart industrial automation .

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB B5EEd HENF105082R4 |

| Manufacturer | ABB |

| Product Type | Electronic Motor Protection Relay |

| Rated Voltage | 24–250 V AC/DC (universal input) |

| Current Range | 0.1–800 A (adjustable via CTs) |

| Trip Classes | 5, 10, 20, 30 (IEC 60947-4-1) |

| Communication Protocols | Modbus RTU, Ethernet/IP, Profibus DP |

| Inputs/Outputs | 4x analog inputs, 3x digital outputs (relays) |

| Accuracy | ±0.25% of reading (25°C) |

| Operating Temperature | -40°C to +70°C |

| Enclosure Rating | IP20 |

| Mounting | 35 mm DIN rail or panel |

| Weight | 0.6 kg |

| Certifications | ATEX, UL 508, CE EN 61010-1 |

Key Features and Advantages

Advanced Protection Capabilities:

The ABB B5EEd HENF105082R4 offers comprehensive fault protection against overload, phase loss, voltage unbalance, and ground faults, with adjustable time-current characteristics to match motor dynamics. Its thermal model with memory simulates winding temperature in real time, preventing overheating even under variable loads .

The ABB B5EEd HENF105082R4 offers comprehensive fault protection against overload, phase loss, voltage unbalance, and ground faults, with adjustable time-current characteristics to match motor dynamics. Its thermal model with memory simulates winding temperature in real time, preventing overheating even under variable loads .

Smart Connectivity:

With support for Modbus RTU, Ethernet/IP, and Profibus DP, the relay enables seamless integration into Industry 4.0 ecosystems. Data logging of up to 100 fault events with timestamps facilitates root-cause analysis, while remote configuration via web interface reduces commissioning time by 50% .

With support for Modbus RTU, Ethernet/IP, and Profibus DP, the relay enables seamless integration into Industry 4.0 ecosystems. Data logging of up to 100 fault events with timestamps facilitates root-cause analysis, while remote configuration via web interface reduces commissioning time by 50% .

Energy Efficiency Monitoring:

The relay tracks real-time energy consumption and power quality metrics (THD, PF), helping users identify inefficiencies and optimize motor operation. This feature supports ISO 50001 energy management systems and can achieve 8–12% energy savings in typical applications .

The relay tracks real-time energy consumption and power quality metrics (THD, PF), helping users identify inefficiencies and optimize motor operation. This feature supports ISO 50001 energy management systems and can achieve 8–12% energy savings in typical applications .

Rugged Industrial Design:

Built to withstand extreme conditions, the relay features reinforced isolation between channels and a wide temperature range (-40°C to +70°C). The hot-swap capability allows module replacement without system shutdown, while vibration resistance (50 G peak) makes it suitable for heavy machinery .

Built to withstand extreme conditions, the relay features reinforced isolation between channels and a wide temperature range (-40°C to +70°C). The hot-swap capability allows module replacement without system shutdown, while vibration resistance (50 G peak) makes it suitable for heavy machinery .

Application Areas

Manufacturing:

Ideal for conveyor systems, robotic arms, and packaging machinery, the ABB B5EEd HENF105082R4 ensures continuous operation by protecting motors from transient faults. Its quick trip response (≤50 ms) safeguards against sudden load spikes in automotive assembly lines .

Ideal for conveyor systems, robotic arms, and packaging machinery, the ABB B5EEd HENF105082R4 ensures continuous operation by protecting motors from transient faults. Its quick trip response (≤50 ms) safeguards against sudden load spikes in automotive assembly lines .

Energy Sector:

Deployed in turbine cooling systems, generator exciters, and solar tracking motors, the relay maintains reliability in power plants. The ATEX certification allows use in hazardous areas of oil & gas refineries .

Deployed in turbine cooling systems, generator exciters, and solar tracking motors, the relay maintains reliability in power plants. The ATEX certification allows use in hazardous areas of oil & gas refineries .

Water/Wastewater:

In pump stations and aeration systems, the relay monitors motors in corrosive environments, ensuring compliance with environmental standards. Its wide voltage tolerance stabilizes operation during utility grid fluctuations .

In pump stations and aeration systems, the relay monitors motors in corrosive environments, ensuring compliance with environmental standards. Its wide voltage tolerance stabilizes operation during utility grid fluctuations .

Mining and Metals:

Used in crushers, conveyors, and smelting equipment, the relay withstands high vibrations and dust exposure. The thermal memory feature prevents premature restarting of overheated motors in continuous processing .

Used in crushers, conveyors, and smelting equipment, the relay withstands high vibrations and dust exposure. The thermal memory feature prevents premature restarting of overheated motors in continuous processing .

Related Products

- ABB Emax 2 E2B2500: A high-current circuit breaker with integrated motor protection, compatible with the B5EEd HENF105082R4 in large MCCs.

- ABB S800 I/O Modules (AI810, DI810): Expandable I/O modules for analog/digital signals, enhancing the relay’s connectivity in DCS setups.

- ABB AC500 PLC PM590-ETH: A modular PLC for motor control, often paired with the relay for centralized automation.

- ABB Ability Smart Sensor: A wireless sensor suite that integrates with the relay for predictive maintenance in remote assets.

- ABB TB810 Terminal Block: Standardized wiring solution for secure connections to field devices.

Installation and Maintenance

Installation Preparation:

Before installing the ABB B5EEd HENF105082R4, verify the power supply voltage (24–250 V AC/DC) and select current transformers (CTs) matching the motor’s full-load current. Mount the relay on a 35 mm DIN rail in a ventilated control cabinet, allowing 20 mm clearance for heat dissipation. Connect CTs to terminals X1–X3 and configure communication protocols via ABB’s Automation Builder software, ensuring IP address compatibility with the plant network .

Before installing the ABB B5EEd HENF105082R4, verify the power supply voltage (24–250 V AC/DC) and select current transformers (CTs) matching the motor’s full-load current. Mount the relay on a 35 mm DIN rail in a ventilated control cabinet, allowing 20 mm clearance for heat dissipation. Connect CTs to terminals X1–X3 and configure communication protocols via ABB’s Automation Builder software, ensuring IP address compatibility with the plant network .

Maintenance Recommendations:

- Routine Checks: Monthly visual inspection for loose connections or dust accumulation. Use the LCD interface to review real-time diagnostics and clear fault logs.

- Calibration: Annually verify current/voltage accuracy using a traceable multimeter. Replace CTs if signal error exceeds ±0.5%.

- Firmware Updates: Quarterly updates via ABB’s Online Support Portal to enable new features like harmonic analysis or cybersecurity patches.

- Environmental Control: Maintain ambient temperature below +70°C and humidity below 95% non-condensing. Clean the enclosure vents quarterly with compressed air.

Product Assurance

ABB guarantees the ABB B5EEd HENF105082R4 against defects in materials and workmanship for 1 year from purchase. The company provides 24/7 global technical support, including remote diagnostics via secure VPN access. ABB’s network of certified service centers ensures 48-hour response times for critical issues, while online resources (3D models, configuration guides) support seamless integration. With a focus on sustainability, the relay is RoHS-compliant and designed for a 10+ year service life, minimizing environmental impact .

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com