Description

Product Overview

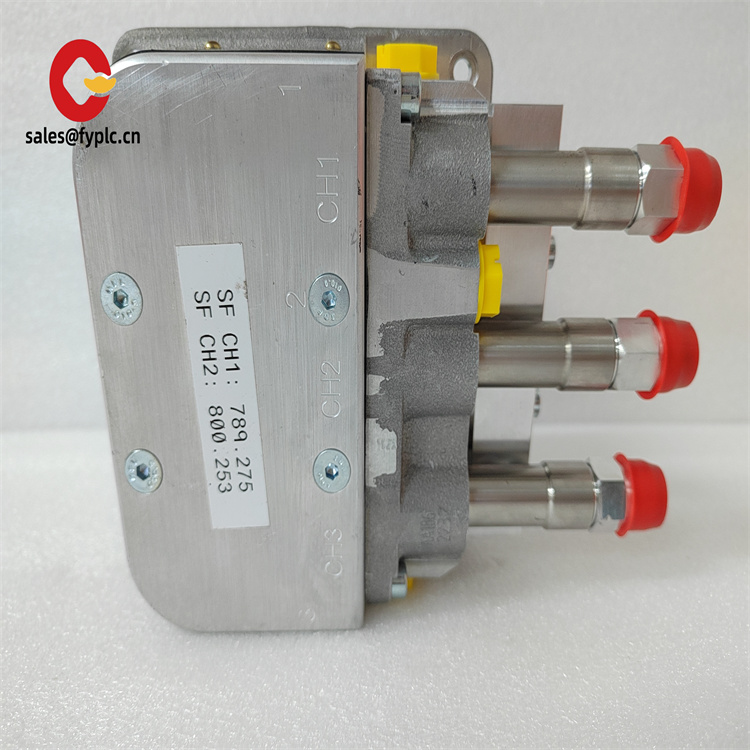

The ABB ACU-01B is a high-performance air control unit (ACU) designed for precision air regulation in industrial robotic applications, particularly spray painting systems. As a core component of ABB’s Integrated Process System (IPS), the ABB ACU-01B delivers millisecond-level response times to control air pressure and atomizer turbine speed, ensuring consistent spray patterns and material deposition across complex surfaces1620. It is specifically engineered for integration with ABB’s IRB 5400, IRB 5500, and IRB 580 paint robots, providing closed-loop air control with ±1% accuracy and support for advanced features like StayOn™ (continuous material flow) and NoPatch™ (edge detection optimization)920.

Key features include a compact, lightweight design (210 x 140 x 160 mm, 3.66 kg) that mounts directly on the robot arm, reducing pneumatic lag and enabling high-acceleration movements without compromising stability714. The ABB ACU-01B supports plug-and-play integration with pre-calibrated settings, while its modular architecture allows easy customization for different spray guns, atomizers, and paint viscosities. It also incorporates explosion-proof encapsulation (IP67-rated) and dual-channel safety monitoring to comply with hazardous environment standards1620.

The ABB ACU-01B interfaces with robot controllers via Profibus DP or Ethernet/IP, enabling real-time adjustments to air flow rates (0.5–10 bar) and atomizer speeds (up to 100,000 RPM). Its built-in diagnostics and data logging (via SD card) facilitate predictive maintenance by tracking pressure fluctuations, valve wear, and system performance over time716.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB ACU-01B (3HNA024871-001) |

| Manufacturer | ABB |

| Product Type | Air Control Unit (ACU) for robotic spray systems |

| Power Supply | 24 VDC ±10% (100 W max.) |

| Air Pressure Range | 0.5–10 bar |

| Air Flow Capacity | Up to 100 L/min |

| Communication Protocols | Profibus DP, Ethernet/IP, CANopen |

| Control Accuracy | ±1% of setpoint |

| Response Time | ≤5 ms (pressure adjustment), ≤10 ms (atomizer speed change) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 210 mm (depth) x 140 mm (height) x 160 mm (width) |

| Weight | 3.66 kg |

| Safety Certification | CE, UL 508, ATEX Zone 1/21 (explosion-proof) |

| Environmental Compliance | IP67, IEC 61000-6-4 (EMC), ISA-S71.04 G3 (corrosion resistance) |

| Mounting | Directly on robot arm (e.g., IRB 5500) |

Key Features and Advantages

Precision Air Regulation: The ABB ACU-01B achieves millisecond-level response times to adjust air pressure and atomizer speed, minimizing overspray and material waste. Its closed-loop feedback control (using integrated pressure and flow sensors) ensures consistent droplet size and spray pattern uniformity across dynamic robotic movements916.

Robust Industrial Design: With IP67-rated encapsulation and corrosion-resistant materials (ISA-S71.04 G3), the ABB ACU-01B withstands harsh environments, including exposure to solvents, dust, and extreme temperatures. Its vibration-damped mounting brackets reduce mechanical stress during high-velocity robot maneuvers1420.

Seamless Integration: The ABB ACU-01B is fully compatible with ABB’s IPS software suite, enabling centralized control of spray parameters (e.g., fan width, material flow rate) alongside robot motion planning. It supports hot-swappable modules for quick replacement of valves or sensors without system downtime1620.

Advanced Diagnostics: Built-in real-time monitoring tracks critical metrics like air flow stability, valve actuation cycles, and temperature gradients. The unit’s SD card data logging records process data for offline analysis, aiding in root-cause failure analysis and predictive maintenance scheduling716.

Cost-Effective Retrofit: Designed as a drop-in replacement for legacy systems (e.g., PPRU units in S4P/S4P+ robots), the ABB ACU-01B requires minimal hardware modifications and preserves existing control logic, reducing retrofit costs by up to 30%1620.

Application Areas

The ABB ACU-01B is widely deployed in industries requiring high-precision robotic spraying:

- Automotive Manufacturing: Controlling paint atomization for car body finishing, ensuring uniform coating thickness and reducing overspray by 15–20%. Its StayOn™ feature maintains continuous material flow during robot pauses, eliminating drips and improving surface quality1620.

- Aerospace: Managing spray patterns for aircraft component painting, including wing sections and engine parts. The ABB ACU-01B’s NoPatch™ technology optimizes edge coverage, critical for adhering to FAA and EASA coating standards20.

- Industrial Coatings: Regulating powder coating processes for machinery and infrastructure. Its variable air pressure profiles adapt to different powder viscosities, ensuring consistent electrostatic adhesion14.

- Woodworking and Furniture: Enabling precise lacquer and stain application on complex wooden surfaces. The unit’s modular valve design supports quick changes between spray guns (e.g., HVLP vs. airless)9.

- Adhesive Dispensing: Controlling bead width and pressure for automotive gasket assembly. The ABB ACU-01B’s closed-loop feedback compensates for adhesive viscosity variations, ensuring joint integrity16.

Related Products

- IRB 5400/5500/580 Paint Robots: ABB’s spray robot platforms optimized for high-speed, high-precision applications, fully compatible with the ABB ACU-01B916.

- IPS Software Suite: ABB’s integrated process control software for configuring spray parameters, motion paths, and system diagnostics20.

- SD822 Redundant Power Supply: 24 VDC power module with surge protection, ensuring stable operation of the ABB ACU-01B in voltage-sensitive environments1.

- TA951F Backup Battery: Lithium battery for retaining configuration data during power outages, critical for continuous production lines1.

- BCU-01 Control Unit: Fiber-optic interface module for connecting the ABB ACU-01B to robot controllers (e.g., IRC5), supporting real-time data exchange15.

- S800 I/O Modules: High-density analog/digital I/O modules for expanding sensor and actuator connectivity in robotic cells18.

- CI930F Profibus DP Module: Communication interface for integrating the ABB ACU-01B with third-party devices (e.g., PLCs, HMIs)1.

- Virtual ACU Simulation Tool: Software for offline testing of spray parameters and control logic, reducing commissioning time by 20%1.

- ABB Atomizers (e.g., Bell 460): Complementary spray guns designed to work seamlessly with the ABB ACU-01B for optimal atomization quality16.

- Lifetime Care Service: ABB’s maintenance program offering firmware updates, remote diagnostics, and priority technical support for the ABB ACU-01B1.

Installation and Maintenance

Installation:

- Mounting: Secure the ABB ACU-01B directly on the robot arm using M6 screws, ensuring alignment with the spray gun. Use vibration-damped brackets to minimize mechanical stress during high-acceleration movements1420.

- Wiring: Connect 24 VDC power cables to the terminal block (±Polarity marked). Route Profibus DP/Ethernet cables through the robot’s cable management system, using shielded connectors to reduce EMI interference716.

- Configuration: Use ABB IPS Software to calibrate air pressure setpoints, map I/O signals, and configure safety interlocks. Import third-party device profiles (e.g., spray gun GSD files) via the Device Import Wizard120.

Maintenance:

- Routine Checks: Inspect air filters monthly for debris accumulation, replacing them if pressure drop exceeds 0.2 bar. Clean dust from the unit’s vents using compressed air1416.

- Valve Servicing: Lubricate solenoid valves annually with food-grade grease (e.g., ABB-approved silicone-based lubricant). Replace O-rings every 2,000 operating hours to prevent air leaks20.

- Firmware Updates: Regularly update firmware via ABB IPS Software to access new features and security patches. Verify compatibility with existing robot controller software versions1.

- Redundancy Testing: Perform quarterly failover tests for redundant power supplies (e.g., SD822) to ensure uninterrupted operation. Replace backup batteries (TA951F) every 3 years116.

- Spare Parts Management: Maintain inventory of critical components (e.g., solenoid valves, pressure sensors) to reduce downtime. ABB offers expedited delivery for urgent replacements120.

Product Assurance

The ABB ACU-01B is backed by a 2-year warranty covering defects in materials and workmanship. ABB provides global technical support, including access to certified engineers and comprehensive documentation (e.g., datasheets, installation manuals). For mission-critical applications, ABB offers extended warranties (up to 5 years) and proactive maintenance plans, including annual system health checks to ensure compliance with safety standards120.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com