Description

Product Overview

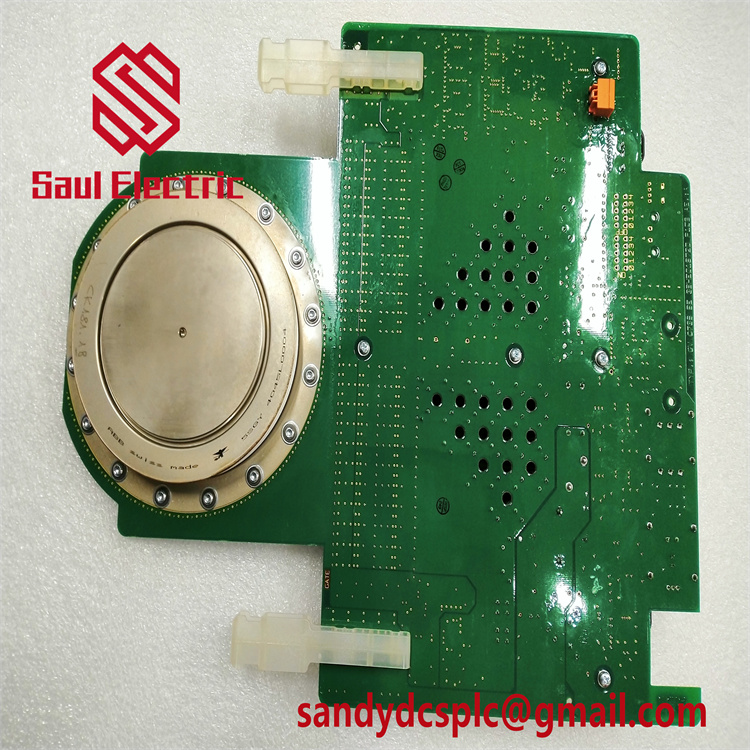

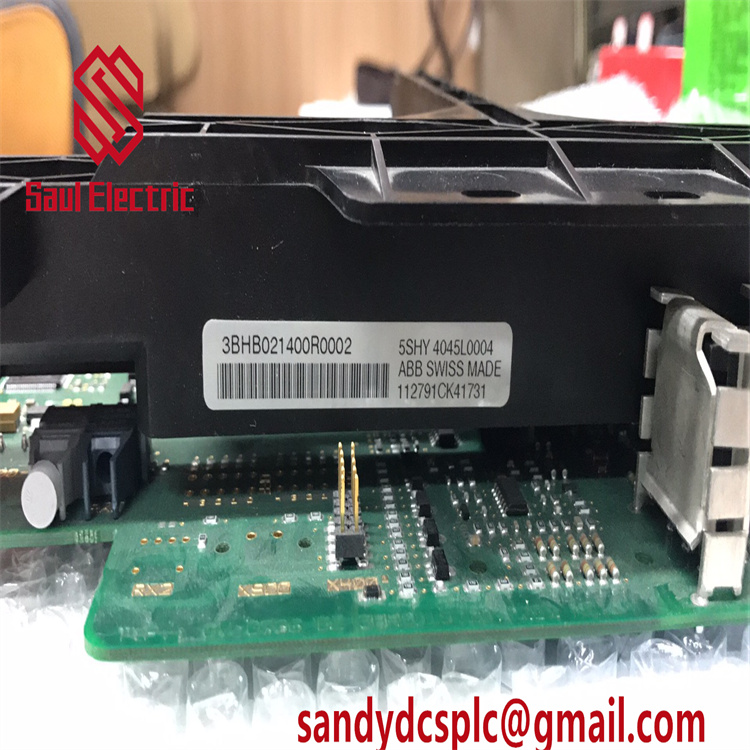

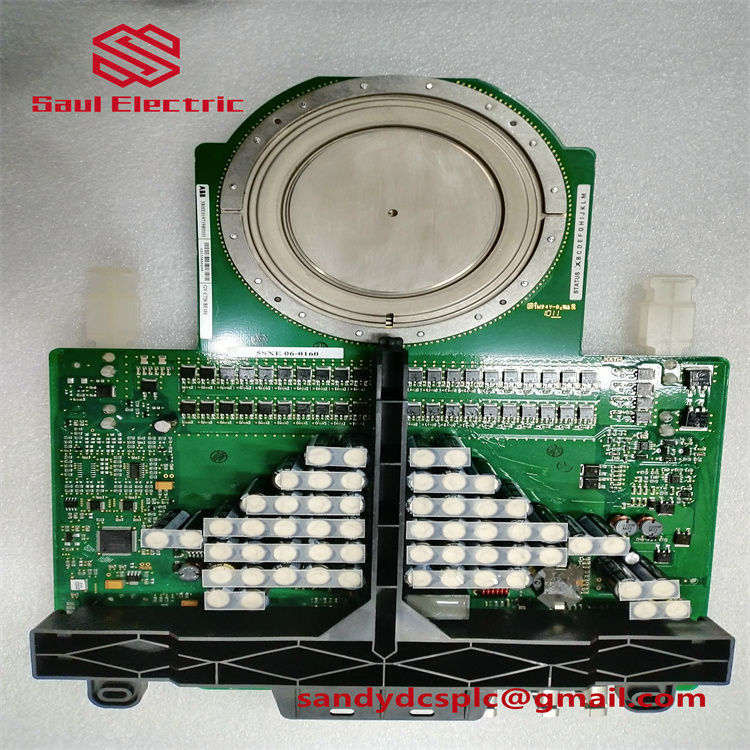

The ABB 5SHY4045L0006 is a high-reliability protective control module designed for critical industrial applications requiring advanced fault detection and circuit protection. As part of ABB’s 5SHY series, this module combines precision voltage/current monitoring with rapid response capabilities, making it ideal for safeguarding high-value equipment in sectors such as energy generation, oil & gas, and heavy manufacturing. The ABB 5SHY4045L0006 integrates a dual-channel protection circuit with configurable trip thresholds, enabling real-time monitoring of electrical parameters to prevent damage from overvoltage, undervoltage, or overcurrent conditions.

Rated for 24 VDC operation and capable of handling 5 A continuous current, the ABB 5SHY4045L0006 features hot-swappable design for seamless maintenance in live systems. Its compact form factor (100 x 80 x 60 mm) and DIN rail mounting compatibility simplify integration into existing control panels. The module supports multiple communication protocols (e.g., Modbus RTU, Profibus DP) for remote diagnostics and configuration, while its SIL 2 certification ensures compliance with rigorous safety standards. With a wide operating temperature range (-40°C to +85°C), the ABB 5SHY4045L0006 delivers consistent performance in harsh industrial environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB 5SHY4045L0006 |

| Manufacturer | ABB |

| Product Type | Protective Control Module |

| Voltage Rating | 24 VDC ±10% |

| Current Rating | 5 A (continuous), 10 A (peak) |

| Input Configuration | Differential/Single-ended |

| Protection Functions | Overvoltage, Undervoltage, Overcurrent, Phase Loss |

| Trip Response Time | <5 ms |

| Communication Protocol | Modbus RTU, Profibus DP (optional) |

| I/O Interfaces | 4x Digital Inputs, 2x Relay Outputs |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 100 x 80 x 60 mm |

| Weight | 0.3 kg |

| Safety Certification | SIL 2, CE, UL, CSA |

Key Features and Advantages

Comprehensive Fault Protection: The ABB 5SHY4045L0006 monitors voltage and current in real-time, triggering precise trip actions to protect downstream equipment from damage. Its dual-channel architecture ensures redundancy, with independent fault detection for each phase in three-phase systems.

Hot-Swappable Design: The module supports online replacement without system shutdown, minimizing downtime during maintenance. This feature is critical in continuous-process industries like chemical plants and data centers, where even brief interruptions can lead to significant losses.

Flexible Configuration: Users can adjust trip thresholds, response times, and communication parameters via ABB’s DriveWindow software or local pushbuttons. Customizable alarm settings (e.g., audible/visual alerts) provide actionable insights for predictive maintenance.

Wide Compatibility: The module interfaces seamlessly with ABB’s industrial drives (e.g., ACS880) and third-party PLCs, enabling integration into diverse automation systems. Optional fieldbus adapters (e.g., EtherCAT, Ethernet/IP) enhance connectivity for Industry 4.0 applications.

Robust Construction: Built with industrial-grade components, the ABB 5SHY4045L0006 withstands high vibration, humidity, and electromagnetic interference (EMI). Its conformal coating protects against dust and corrosive environments, ensuring long-term reliability in offshore platforms and mining operations.

Application Areas

The ABB 5SHY4045L0006 is widely adopted in industries requiring precision and reliability:

- Power Generation: Protects generators, transformers, and switchgear from voltage fluctuations and short circuits in thermal, hydroelectric, and renewable energy plants.

- Oil & Gas: Monitors critical pumps and compressors in offshore platforms and refineries, preventing equipment failure due to overloading or phase imbalances.

- Water Treatment: Ensures stable operation of motors and drives in wastewater treatment facilities, minimizing downtime during filtration and disinfection processes.

- Manufacturing: Safeguards CNC machines, robotics, and conveyor systems in automotive and electronics production lines, reducing unplanned maintenance costs.

- Marine Applications: Integrates into shipboard power systems to protect propulsion motors and auxiliary equipment from voltage spikes and harmonic distortions.

Related Products

- Best ABB 5SHY3545L0003 3BHB004692R0001 GVC732

- 5shy3545l0005 – 5SHY3545L0005 – 3BHE009681R0101

- 5SHY3545L0009 IGCT Control Panel ABB Brand New

- ABB 5SHY3545L0010 3BHB013088R000 Silicon

- ABB 5SHY3545L0014 3BHE023784R0001 IGCT Module

- ABB 5SHY35L4510

Installation and Maintenance

Installation Preparation:

Before installing the ABB 5SHY4045L0006, verify the system voltage and current ratings match the module’s specifications. Use ABB’s DriveWindow software to configure protection thresholds and enable communication protocols. Ensure proper grounding and shielded cabling to minimize EMI interference. For three-phase applications, connect the module to each phase via current transformers (CTs) and voltage sensors.

Before installing the ABB 5SHY4045L0006, verify the system voltage and current ratings match the module’s specifications. Use ABB’s DriveWindow software to configure protection thresholds and enable communication protocols. Ensure proper grounding and shielded cabling to minimize EMI interference. For three-phase applications, connect the module to each phase via current transformers (CTs) and voltage sensors.

Maintenance Recommendations:

Regularly inspect the ABB 5SHY4045L0006 for loose connections or physical damage, especially in high-vibration environments. Utilize the module’s built-in diagnostics to monitor channel health and review fault logs. Replace worn-out components (e.g., relay contacts) according to ABB’s maintenance schedule, typically every 5,000 operating hours. Clean the module’s vents periodically to prevent dust accumulation and ensure optimal cooling.

Regularly inspect the ABB 5SHY4045L0006 for loose connections or physical damage, especially in high-vibration environments. Utilize the module’s built-in diagnostics to monitor channel health and review fault logs. Replace worn-out components (e.g., relay contacts) according to ABB’s maintenance schedule, typically every 5,000 operating hours. Clean the module’s vents periodically to prevent dust accumulation and ensure optimal cooling.

Product Assurance

The ABB 5SHY4045L0006 is backed by a 1-year warranty covering defects in materials and workmanship. ABB provides global technical support, including access to certified engineers and comprehensive documentation. Replacement modules are available from spot inventory, with delivery within 3 days after payment. For mission-critical applications, optional extended warranties and proactive maintenance plans offer priority access to spare parts and annual system health checks, ensuring maximum uptime and compliance with international safety standards.

HS:8443919090

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com