Description

ABB 500BIO01 1MRB150005R0001 1MRB200060/E: High-Reliability Binary I/O Module for AC500 PLCs

Product Overview

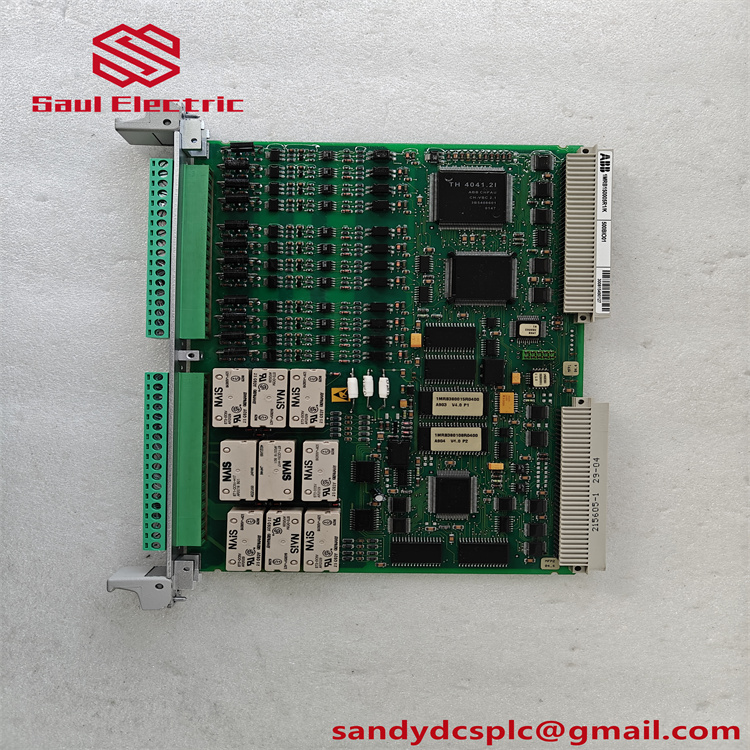

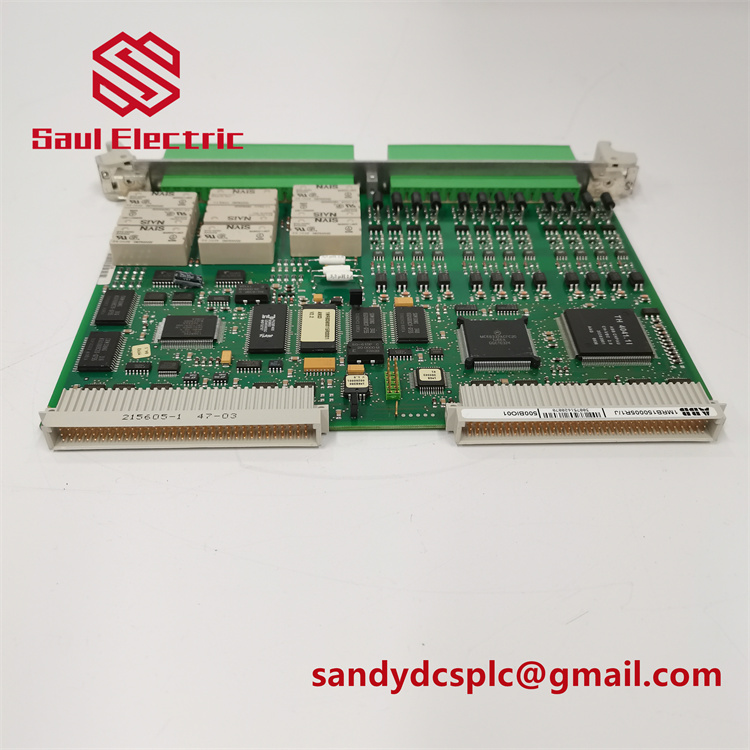

The ABB 500BIO01 1MRB150005R0001 1MRB200060/E is a binary input/output (I/O) module designed for ABB’s AC500 series programmable logic controllers (PLCs). Engineered for industrial automation, this module serves as a critical interface between field devices and the PLC, enabling real-time monitoring and control of binary signals from sensors, switches, solenoids, and other discrete devices. The 500BIO01 features 16 isolated I/O channels with 24 V DC compatibility, making it suitable for harsh industrial environments.

Part of ABB’s AC500 ecosystem, the 500BIO01 R0001 supports standard industrial voltage ranges (20.4–28.8 V DC) and offers galvanic isolation (2.5 kV) to protect against voltage spikes and electromagnetic interference (EMI). Its rugged IP20-rated enclosure resists dust and moisture, while surge protection safeguards against faulty field devices. The module integrates seamlessly with ABB’s AC500 PLC platform, enabling efficient configuration via ABB’s Automation Builder software and ensuring compatibility with existing automation systems. By leveraging the 500BIO01 R0001, manufacturers can enhance process visibility, optimize control accuracy, and reduce downtime in critical operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 500BIO01 1MRB150005R0001 1MRB200060/E |

| Manufacturer | ABB |

| Product Type | Binary I/O Module (AC500 Series) |

| I/O Channels | 16 isolated channels (8 inputs + 8 outputs) |

| Signal Type | 24 V DC (20.4–28.8 V DC) |

| Isolation | Galvanic isolation (2.5 kV) |

| Response Time | ≤5 ms (adjustable via software) |

| Input Protection | Overvoltage protection (±30 V DC) |

| Output Protection | Overcurrent/short-circuit protection |

| Communication | Serial via AC500 PLC backplane (S2I bus) |

| Power Supply | 24 VDC (from PLC backplane) |

| Operating Temperature | -25°C to +70°C |

| Dimensions (W×H×D) | 36 mm × 175 mm × 110 mm |

| Weight | 0.3 kg |

| Certifications | CE, UL, cUL, ATEX (Zone 2), IECEx |

Key Features and Advantages

Dual-Function I/O Design: Combines 8 digital inputs and 8 digital outputs in a single module, reducing cabinet space and simplifying wiring. Each channel is galvanically isolated to prevent cross-channel interference.

Industrial-Grade Robustness: EMI-shielded circuitry and surge protection ensure reliable operation in high-noise environments. The IP20-rated enclosure resists dust and moisture, while overcurrent protection safeguards against faulty field devices.

High-Speed Signal Handling: With a response time of ≤5 ms and adjustable signal filtering, the 500BIO01 R0001 ensures accurate detection of fast-acting events, such as proximity sensor triggers or solenoid valve commands.

Universal Compatibility: Designed for 24 V DC inputs/outputs, the module interfaces seamlessly with standard industrial sensors, limit switches, and solenoid valves, eliminating the need for external signal conditioners. This versatility streamlines inventory management, as a single module can support diverse devices across an entire plant.

Plug-and-Play Integration: Hot-swappable design allows module replacement without powering down the PLC, minimizing downtime during maintenance. ABB’s Automation Builder software enables auto-detection of signal types and real-time diagnostics, reducing commissioning time by 30%.

Energy-Efficient Design: Low power consumption (≤2.5 W) and optimized signal conditioning reduce energy costs. The module’s compact form factor supports dense I/O configurations, saving up to 40% cabinet space in large-scale systems.

Application Areas

The ABB 500BIO01 R0001 excels in industrial settings requiring reliable monitoring and control of binary signals:

- Manufacturing: Controls conveyor belt sensors, robotic arm actuators, and machine safety interlocks in automotive assembly lines.

- Process Control: Monitors pressure switches, level sensors, and actuates solenoid valves in chemical reactors and water treatment plants.

- Power Generation: Tracks turbine overspeed switches, generator breaker statuses, and controls auxiliary equipment in power plants.

- Food & Beverage: Manages packaging machine safety interlocks, filling station sensors, and actuates pasteurization process valves.

- Mining: Supports haul truck proximity detection, conveyor belt alignment switches, and controls ventilation system actuators.

Related Products

- ABB 500BOM01: 12-channel digital output module for relay control, often paired with 500BIO01 in mixed I/O systems.

- ABB 500DI09: 16-channel digital input module with 24 V DC compatibility, complementary to 500BIO01 for large-scale monitoring.

- ABB PM590-ETH: AC500 PLC processor with Ethernet, serving as the controller for 500BIO01 modules.

- ABB 500TAP01: Terminal adapter plate for simplified field wiring of 500BIO01.

- ABB 500PWR12: 24 VDC power supply for AC500 backplanes, ensuring stable power to 500BIO01.

- ABB S500-CPU-900: High-performance PLC for complex systems integrating multiple 500BIO01 modules.

- ABB 500MBA02: Communication control module for Profibus/Modbus integration with 500BIO01.

Installation and Maintenance

Installation Preparation:

- Power off the AC500 PLC and ensure the backplane is grounded before installing the 500BIO01 R0001. Mount the module on a DIN rail using the included clips, leaving 10 mm clearance for airflow.

- Use shielded twisted-pair cables for signal wiring to minimize interference. Follow ABB’s wiring diagrams to connect sensors and actuators, ensuring proper polarity and loop continuity.

- Configure the module via Automation Builder software, enabling signal filtering and diagnostics for real-time error monitoring.

Maintenance Recommendations:

- Quarterly: Inspect terminal blocks for loose connections and clean the module with compressed air to remove dust.

- Annually: Use the PLC’s diagnostic tools to verify channel accuracy. Replace faulty channels or cables if signal degradation is detected.

- Firmware Updates: Apply ABB’s latest firmware for R0001 modules to access bug fixes and compatibility improvements, especially when integrating with new PLC software versions.

Product Warranty

ABB warrants the 500BIO01 1MRB150005R0001 1MRB200060/E against defects for 1 year from purchase. This coverage includes repair or replacement of faulty components, provided the module is used within specifications. ABB’s global support network offers 24/7 technical assistance, with certified engineers available for on-site troubleshooting. For critical applications, extended warranty plans (up to 3 years) are available, including priority service and preventive maintenance visits.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com