Description

ABB 500AIM02 1MRB150022 R0002 1HDF 930412 X010: High-Precision Analog Input Module for Industrial Automation

Product Overview

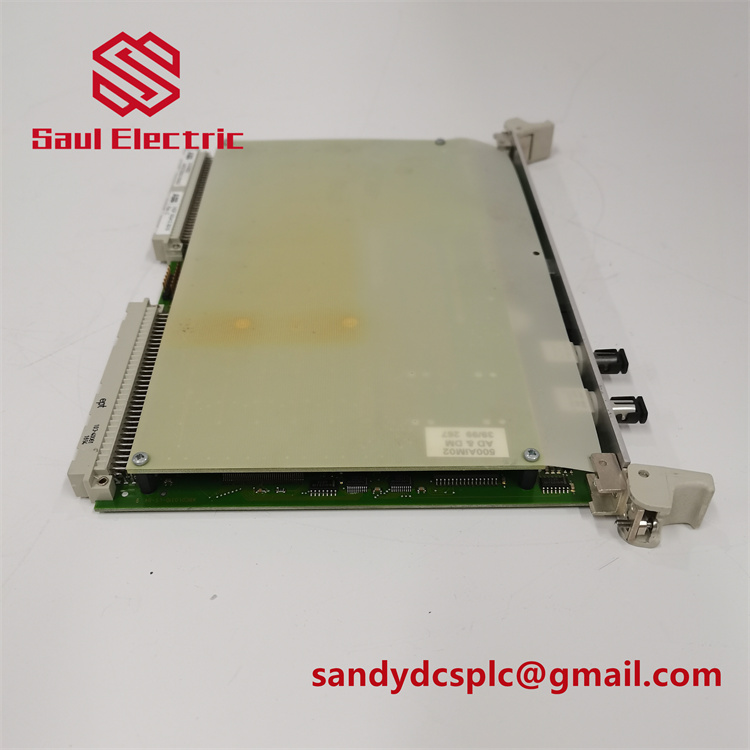

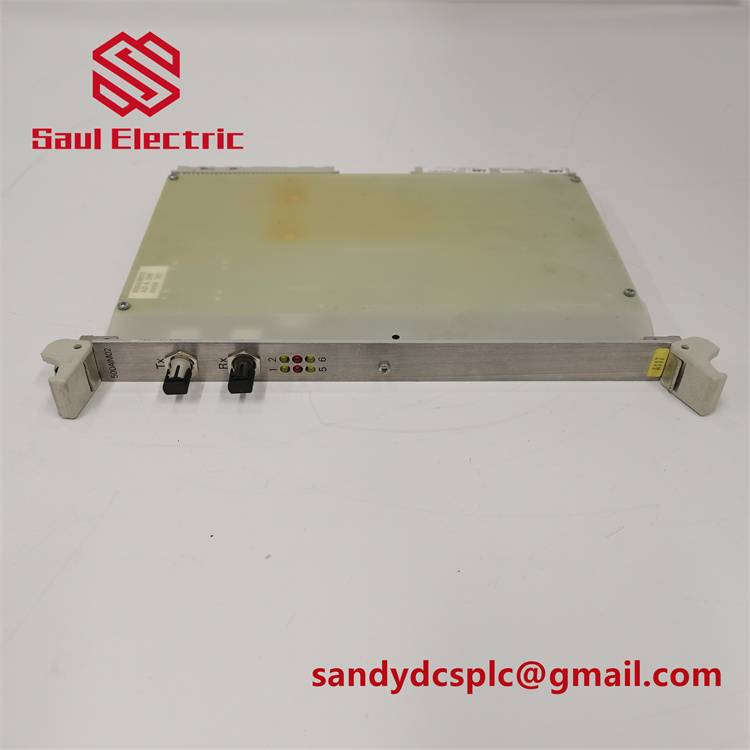

The ABB 500AIM02 1MRB150022 R0002 1HDF 930412 X010 is a high-performance analog input module designed for ABB’s AC500 series programmable logic controllers (PLCs). Engineered for industrial process control, this module serves as a critical interface between field sensors and the PLC, enabling real-time data acquisition from analog devices such as pressure transmitters, temperature sensors, and flow meters. The 500AIM02 features 8 isolated input channels with 16-bit resolution, ensuring precise conversion of analog signals to digital data for processing by the PLC.

Part of ABB’s advanced automation portfolio, the 500AIM02 supports multiple signal types, including 4–20 mA, 0–10 V, and thermocouple inputs, making it versatile for diverse industrial applications. Its rugged design withstands harsh environments, with built-in overvoltage protection and electromagnetic interference (EMI) shielding to maintain signal integrity. The module integrates seamlessly with ABB’s AC500 PLC platform, enabling efficient configuration via ABB’s Control Builder software and ensuring compatibility with existing automation systems. By leveraging the 500AIM02, manufacturers can enhance process visibility, optimize control accuracy, and reduce downtime in critical operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 500AIM02 1MRB150022 R0002 1HDF 930412 X010 |

| Manufacturer | ABB |

| Product Type | Analog Input Module (AC500 Series) |

| Input Channels | 8 isolated channels |

| Signal Types | 4–20 mA, 0–10 V, ±10 V, thermocouple (J, K, T, E, R, S, B, N types) |

| Resolution | 16-bit (±0.015% of full scale) |

| Sampling Rate | 100 Hz (per channel) |

| Input Protection | Overvoltage protection (±30 V for voltage inputs, ±50 mA for current inputs) |

| Communication | Serial via AC500 PLC backplane (S2I bus) |

| Power Supply | 24 VDC (from PLC backplane) |

| Operating Temperature | -25°C to +70°C |

| Dimensions (W×H×D) | 36 mm × 175 mm × 110 mm |

| Weight | 0.3 kg |

| Certifications | CE, UL, cUL, ATEX (Zone 2), IECEx |

Key Features and Advantages

High Precision and Versatility: The 500AIM02 offers 16-bit resolution for accurate signal conversion, ideal for applications requiring tight control tolerances. Its support for multiple signal types eliminates the need for external signal conditioners, simplifying system design and reducing costs.

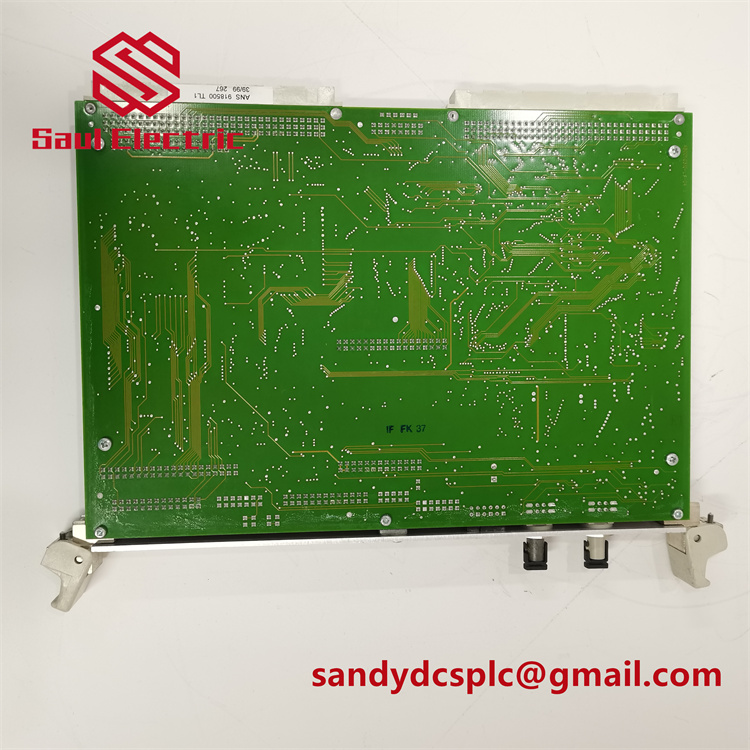

Robust Industrial Design: Built with galvanic isolation between channels and EMI shielding, the module ensures reliable operation in noisy environments. Overvoltage and overcurrent protection mechanisms safeguard against transient spikes, extending the module’s lifespan in harsh industrial settings.

Seamless System Integration: The module plugs directly into the AC500 PLC backplane, enabling hot-swappable replacement without powering down the system. Configuration is streamlined via ABB’s Control Builder software, which supports auto-detection of signal types and real-time diagnostics.

Energy Efficiency: Low power consumption (≤2.5 W) and optimized signal processing reduce energy costs, aligning with sustainable manufacturing initiatives. The module’s compact form factor also minimizes cabinet space, enabling dense I/O configurations.

Advanced Diagnostics: Built-in self-diagnostic features monitor channel health, power supply status, and signal integrity, providing real-time alerts for faulty inputs. This proactive approach reduces unplanned downtime and enables predictive maintenance.

Application Areas

The ABB 500AIM02 is widely used in industrial automation applications across multiple sectors:

- Process Control: Deployed in chemical plants, refineries, and pharmaceutical facilities to monitor temperature, pressure, and flow rates in reactors, distillation columns, and mixing tanks.

- Power Generation: Used in thermal, hydro, and renewable energy plants to interface with sensors with turbines, boilers, and generators, ensuring optimal energy production.

- Water and Wastewater Management: Integrates with treatment plants to measure pH levels, dissolved oxygen, and liquid levels in reservoirs and pipelines.

- Manufacturing: Applied in automotive, food and beverage, and electronics production lines to monitor machine performance, material quality, and process parameters.

- Mining and Metals: Supports ore processing and smelting operations by measuring critical parameters in crushers, mills, and furnaces.

In each application, the 500AIM02 delivers reliable signal acquisition, enabling precise control and data-driven decision-making for enhanced operational efficiency.

Related Products

- ABB 500AI02: Analog input module with 4 channels, suitable for smaller systems requiring fewer inputs.

- ABB 500AO02: Analog output module with 4 channels for controlling valves and actuators, complementary to the 500AIM02.

- ABB 500DI09: Digital input module with 16 channels for discrete signal monitoring.

- ABB 500DO08: Digital output module with 16 channels for controlling relays and solenoids.

- ABB PM590-ETH: AC500 PLC processor with Ethernet connectivity, compatible with the 500AIM02.

- ABB S500-CPU-900: High-performance PLC controller for complex automation systems.

- ABB 500TAP01: Terminal adapter plate for the 500AIM02, simplifying field wiring.

- ABB 500PWR12: Power supply module for AC500 PLC systems, ensuring stable power to the 500AIM02.

Installation and Maintenance

Installation Preparation:

- Ensure the AC500 PLC is powered off and the backplane is grounded before installing the 500AIM02. Mount the module on a DIN rail (EN 50022) using the provided clips, leaving at least 10 mm clearance for heat dissipation.

- Connect field sensors to the module’s terminal block, following ABB’s wiring diagrams to ensure proper polarity and shielding. For thermocouple inputs, use dedicated compensating cables to maintain accuracy.

- Configure the module via ABB’s Control Builder software, selecting the appropriate signal type for each channel and enabling diagnostics for real-time monitoring.

Maintenance Recommendations:

- Regularly inspect the module for loose connections, physical damage, or signs of overheating. Clean the terminal block and enclosure with a dry, lint-free cloth to remove dust and debris.

- Use the PLC’s diagnostic tools to monitor channel status and resolve any fault alerts promptly. For thermocouple inputs, verify cold junction compensation settings and replace cables if signs of wear are detected.

- In harsh environments (e.g., high humidity or dust), perform quarterly inspections and consider applying a protective coating to the module’s circuit board. Replace the module if consistent signal errors or hardware failures occur.

Product Warranty

ABB guarantees the 500AIM02 1MRB150022 R0002 1HDF 930412 X010 against defects in materials and workmanship for 1 year from the date of purchase. This warranty covers repair or replacement of the module, provided it is used in accordance with ABB’s specifications. ABB’s global technical support team offers 24/7 assistance for troubleshooting, configuration, and system optimization. Customers can access ABB’s online resources and training programs to enhance their expertise in PLC integration and maintenance, ensuring long-term reliability of the module.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com