Description

ABB 3HNA023093-001: High-Reliability Power Distribution Board for Industrial Robotic Systems

Product Overview

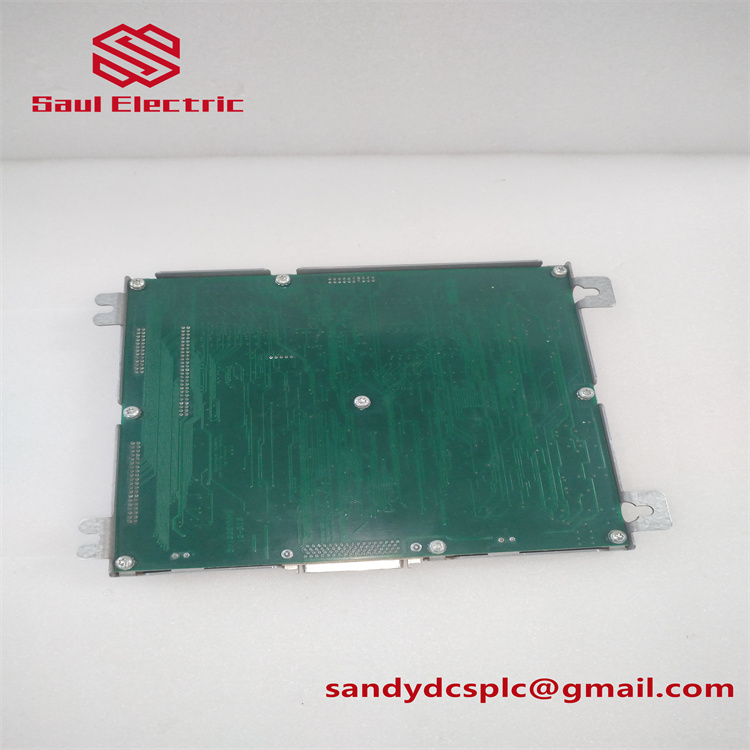

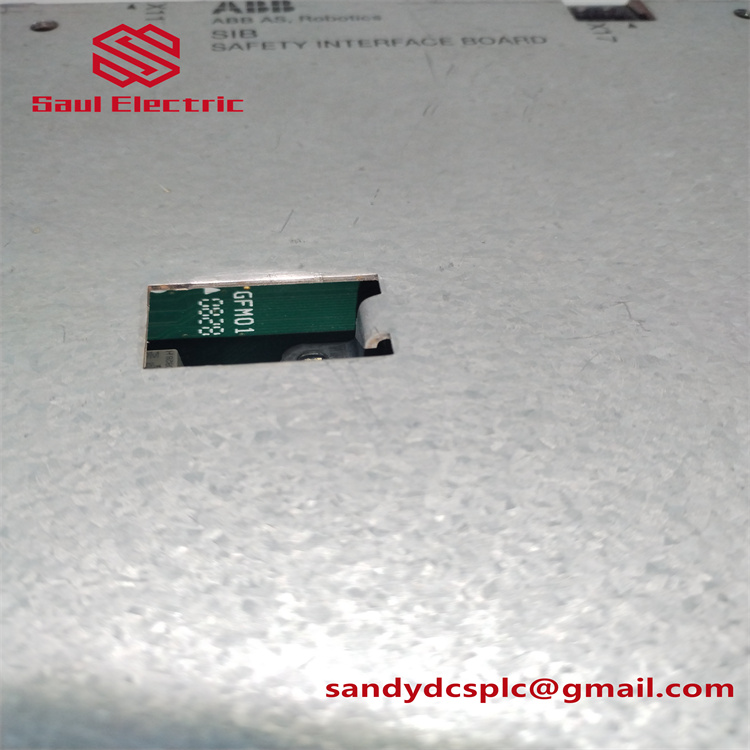

The ABB 3HNA023093-001 is a high-performance Power Distribution Board (PDB-02) designed to provide stable and efficient power management in ABB robotic systems. As part of ABB’s 3HNA series, this module serves as the central hub for distributing electrical power within robot control cabinets, ensuring seamless operation of critical subsystems such as servo drives, controllers, and auxiliary equipment. The PDB-02 is engineered to replace the earlier PDB-01 (3HNA006147-001) model, offering enhanced reliability and compatibility with modern ABB robotics platforms.

Constructed with robust materials and advanced circuit protection mechanisms, the 3HNA023093-001 delivers consistent power distribution under demanding industrial conditions. Its modular design allows for easy integration into existing systems, while redundant safety features ensure compliance with international standards. By leveraging this power distribution board, manufacturers can optimize energy efficiency, reduce downtime, and maintain precise control over robotic processes in high-throughput manufacturing environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 3HNA023093-001 |

| Manufacturer | ABB |

| Product Type | Power Distribution Board (PDB-02) |

| Input Voltage | 43V 3-phase (50/60 Hz) |

| Output Power | 700 VA |

| Current Capacity | 16 A (per phase) |

| Dimensions | 435 mm (L) x 181 mm (W) x 120 mm (H) |

| Weight | 5.77 kg |

| Operating Temperature | -10°C to +55°C |

| Safety Features | Overvoltage/undervoltage protection, short-circuit detection |

| Certifications | CE, UL, CSA |

| Compatibility | ABB IRC5 and OmniCore controllers, IRB robot series (e.g., IRB 6700) |

| Replacement Part | Upgrades PDB-01 (3HNA006147-001) |

Key Features and Advantages

Precision Power Management: The 3HNA023093-001 ensures balanced power distribution to all connected components, minimizing voltage fluctuations and reducing the risk of equipment failure. Its advanced circuit design supports high-efficiency energy transfer, ideal for power-hungry applications like welding and heavy material handling.

Enhanced Safety and Reliability: Built with redundant protection mechanisms, the PDB-02 safeguards against overcurrent, overheating, and short circuits. Real-time status monitoring allows for proactive maintenance, ensuring uninterrupted operation even in 24/7 production environments.

Modular Design for Easy Integration: The PDB-02 is fully compatible with ABB’s latest robotic controllers and can be seamlessly integrated into existing systems. It replaces the older PDB-01 model with improved thermal management and reduced component count, simplifying installation and maintenance.

Space-Saving Form Factor: Despite its high power capacity, the 3HNA023093-001 features a compact design that optimizes cabinet space, making it suitable for retrofitting into legacy robotic systems.

Longevity and Durability: Constructed with corrosion-resistant materials and a sealed housing, the PDB-02 withstands harsh industrial environments, including exposure to dust, oil, and coolant. Its mechanical life exceeds 10,000 hours of continuous operation.

Application Areas

The ABB 3HNA023093-001 is widely used in industrial automation applications requiring reliable power distribution:

- Automotive Manufacturing: Deployed in paint shops and body-in-white assembly lines to power robotic spray guns, weld torches, and conveyor systems.

- Aerospace Component Production: Supports high-precision robotic drilling and composite material layup, ensuring stable power for specialized tools.

- Electronics Assembly: Used in semiconductor packaging and PCB manufacturing to supply power to pick-and-place robots and soldering stations.

- Material Handling: Integrates with robotic palletizing systems and automated storage/retrieval systems (AS/RS) to manage power distribution for heavy payload operations.

- General Industry: Ideal for applications requiring redundant power management, such as food processing, pharmaceutical packaging, and metalworking.

Installation and Maintenance

Installation Preparation:

- Safety Precautions: Power off the robot controller and disconnect all electrical sources before installation.

- Physical Mounting: Secure the PDB-02 to the control cabinet using the provided mounting brackets, ensuring proper alignment with adjacent components.

- Cabling: Connect the 43V 3-phase input power cable and distribute output connections to the robot’s servo drives, I/O modules, and auxiliary equipment. Use ABB-recommended cables (e.g., 3HAC029032-001) for optimal performance.

- Configuration: Update the robot controller firmware to recognize the PDB-02 and configure power management settings via ABB’s RobotStudio software.

Maintenance Recommendations:

- Routine Inspections: Check for loose connections, corrosion, or signs of overheating monthly. Clean the module with a dry cloth to remove dust and debris.

- Thermal Monitoring: Use ABB’s diagnostic tools to monitor temperature levels and ensure the cooling fan (if installed) is functioning correctly.

- Component Replacement: Replace worn-out circuit breakers or fuses as needed. For advanced repairs, contact ABB-certified technicians to avoid voiding the warranty.

- Firmware Updates: Regularly update the PDB-02 firmware to access new features and security patches.

Related Products

- 3HAC031683-004 Cable 30M ABB DSQC679

- 3HAC031683-001

- ABB 3HAC026271-001 | ABB DSQC646

- ABB IRC5 Controller 3HAC025562-001 /06 Capacitor

- 3HAC025466-001 Bay Fan IRC5 REFURBISHED – ABB

- Abb 3HAB9271-1/01B Dummy Drive Unit

- Abb 3HAB8859-1/03A Dc Bus Bar Connecting Strip

- 3HAB8101-8/08Y ROBOTIC SERVO DRIVE

Product Warranty

ABB guarantees the 3HNA023093-001 against manufacturing defects for 1 year from the date of purchase. This warranty covers replacement of faulty components, provided the module is used within specified parameters. ABB’s global service network offers technical support for installation, calibration, and warranty claims, with certified technicians available for on-site assistance. For mission-critical applications, extended warranty plans are available to protect against wear and tear, ensuring long-term reliability.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com