Description

Product Overview

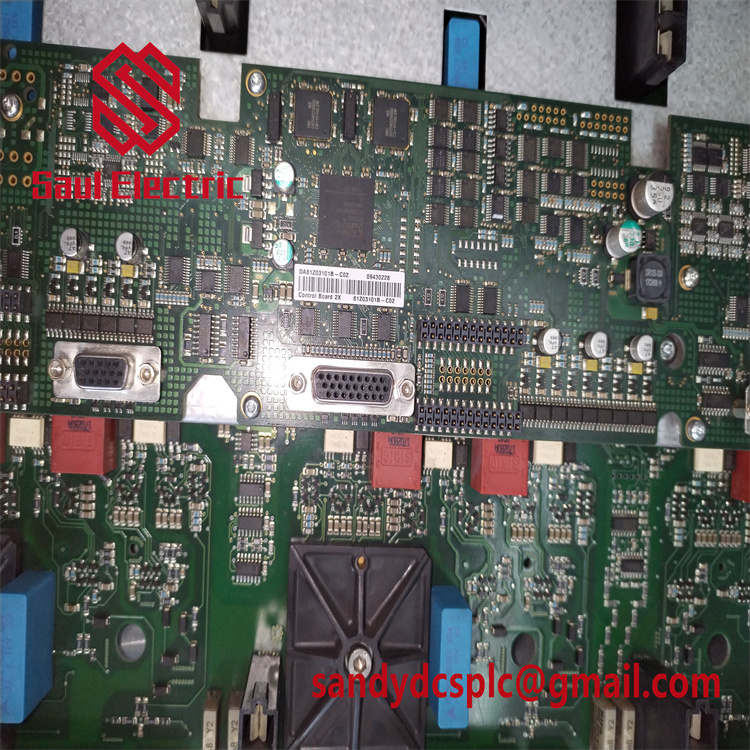

The ABB 3HAC4776-1/1 is a high-performance robot controller interface module designed for ABB’s advanced industrial robotics systems, specifically tailored for integration with the IRC5 controller platform. As a critical component in robotic automation setups, this module facilitates seamless communication between the robot controller and peripheral devices, ensuring precise motion control and system synchronization. The 3HAC4776-1/1 is engineered to handle complex I/O operations, enabling real-time data exchange for tasks such as sensor feedback, actuator control, and safety interlocking in manufacturing environments.

The ABB 3HAC4776-1/1 is a high-performance robot controller interface module designed for ABB’s advanced industrial robotics systems, specifically tailored for integration with the IRC5 controller platform. As a critical component in robotic automation setups, this module facilitates seamless communication between the robot controller and peripheral devices, ensuring precise motion control and system synchronization. The 3HAC4776-1/1 is engineered to handle complex I/O operations, enabling real-time data exchange for tasks such as sensor feedback, actuator control, and safety interlocking in manufacturing environments.

Part of ABB’s robotics automation portfolio, the 3HAC4776-1/1 features a rugged design optimized for 24/7 operation in harsh industrial conditions. Its modular architecture allows for easy integration into existing robotic cells, while advanced diagnostic capabilities minimize downtime by identifying operational anomalies proactively. With support for multiple communication protocols, this module ensures compatibility with a wide range of industrial networks, making it an essential component for smart factories and automated production lines that require high precision and reliability.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3HAC4776-1/1 |

| Manufacturer | ABB |

| Product Type | Robot Controller Interface Module |

| Power Supply | 24 VDC ±10% (nominal 24 VDC, max. 0.5 A) |

| Communication Interfaces | Ethernet (10/100 Mbps), CANopen, Digital I/O (24 VDC, opto-isolated) |

| Operating Temperature | 0°C to +50°C (non-condensing) |

| Storage Temperature | -20°C to +70°C |

| Physical Dimensions | 150 mm (W) x 100 mm (H) x 50 mm (D) |

| Weight | 0.8 kg |

| Certification | CE, UL, CSA, ISO 13849 (Safety Category 3) |

| I/O Channels | 16 digital inputs / 16 digital outputs (configurable via software) |

Key Features and Advantages

High-Speed Communication: The 3HAC4776-1/1 enables real-time data transfer with Ethernet and CANopen interfaces, ensuring minimal latency for precise robot motion control. Its optimized protocol handling supports synchronized operation across multiple robotic arms in complex workcells.

High-Speed Communication: The 3HAC4776-1/1 enables real-time data transfer with Ethernet and CANopen interfaces, ensuring minimal latency for precise robot motion control. Its optimized protocol handling supports synchronized operation across multiple robotic arms in complex workcells.

Robust Safety Integration: Equipped with safety-rated I/O channels, the module complies with industrial safety standards (ISO 13849), allowing direct connection to emergency stop circuits and safety sensors. This integration reduces the need for external safety relays, simplifying system design.

Easy Configuration and Diagnostics: The module is fully compatible with ABB’s RobotStudio software, enabling intuitive configuration of I/O mappings and communication parameters. Built-in LED indicators and diagnostic tools provide real-time status monitoring, streamlining troubleshooting and maintenance.

Rugged Industrial Design: Constructed with reinforced materials, the 3HAC4776-1/1 withstands vibration, dust, and temperature fluctuations, making it suitable for harsh manufacturing environments. Its hot-swappable design allows module replacement without powering down the system, minimizing production interruptions.

Application Areas

The ABB 3HAC4776-1/1 is widely used in industrial robotics applications across various sectors:

The ABB 3HAC4776-1/1 is widely used in industrial robotics applications across various sectors:

- Automotive Manufacturing: Controls robotic welding, painting, and assembly lines, ensuring precision in vehicle production.

- Electronics Production: Manages delicate pick-and-place operations for semiconductor handling and circuit board assembly.

- Food and Beverage: Enables hygienic robotic packaging and sorting in cleanroom environments, compliant with industry standards.

- Logistics and Warehousing: Integrates with robotic palletizers and material handling systems for efficient inventory management.

- Aerospace: Supports precision robotic drilling, coating, and inspection in aircraft component manufacturing.

Its versatility makes it an ideal choice for any automation setup requiring reliable robot-to-peripheral communication and robust safety features.

Related Products

- 3HAC031683-004 Cable 30M ABB DSQC679

- 3HAC031683-001

- ABB 3HAC026271-001 | ABB DSQC646

- ABB IRC5 Controller 3HAC025562-001 /06 Capacitor

- 3HAC025466-001 Bay Fan IRC5 REFURBISHED – ABB

- Abb 3HAB9271-1/01B Dummy Drive Unit

- Abb 3HAB8859-1/03A Dc Bus Bar Connecting Strip

- 3HAB8101-8/08Y ROBOTIC SERVO DRIVE

These products form a comprehensive ecosystem to support robotic automation, from core control to peripheral integration.

Installation and Maintenance

Installation Preparation:

Ensure the IRC5 controller rack is properly grounded and ventilated. Mount the 3HAC4776-1/1 in a designated slot using the provided screws, and connect power cables (24 VDC) and communication lines (Ethernet/CANopen) with shielded wiring to minimize electromagnetic interference. Verify compatibility with the controller’s firmware version before power-up.

Installation Preparation:

Ensure the IRC5 controller rack is properly grounded and ventilated. Mount the 3HAC4776-1/1 in a designated slot using the provided screws, and connect power cables (24 VDC) and communication lines (Ethernet/CANopen) with shielded wiring to minimize electromagnetic interference. Verify compatibility with the controller’s firmware version before power-up.

Maintenance Recommendations:

- Routine Checks: Inspect module LEDs for normal operation (green indicators for power and communication). Clean dust from ventilation slots quarterly to prevent overheating.

- Firmware Updates: Periodically update firmware via RobotStudio to access new features and security patches.

- Spare Parts Management: Keep a spare 3HAC4776-1/1 on hand for quick replacement in case of failure, reducing downtime.

- Electrical System Verification: Test power supply voltage and ground continuity annually to ensure stable operation.

ABB’s global service network provides technical support and genuine replacement parts, ensuring long-term reliability.

Product Warranty and Support

The ABB 3HAC4776-1/1 is backed by a 1-year warranty covering manufacturing defects. ABB offers 24/7 technical support, including remote diagnostics and software assistance, to optimize system performance. With spot inventory and 3-day delivery after payment, customers benefit from rapid order fulfillment, minimizing production delays.

The ABB 3HAC4776-1/1 is backed by a 1-year warranty covering manufacturing defects. ABB offers 24/7 technical support, including remote diagnostics and software assistance, to optimize system performance. With spot inventory and 3-day delivery after payment, customers benefit from rapid order fulfillment, minimizing production delays.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com