Description

Product Overview

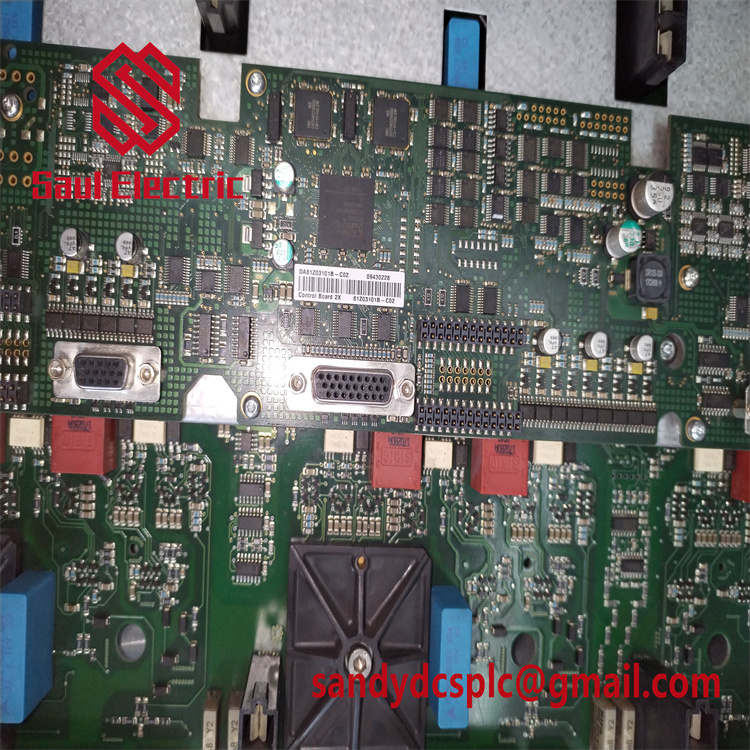

The ABB 3HAC14550-2/09A is a high-performance servo drive module designed for ABB’s industrial robotics systems, specifically engineered to deliver precise motor control and dynamic motion feedback in robotic applications. As part of ABB’s 3HAC series of robotic control components, this servo drive belongs to the second-generation design, optimized for energy efficiency and reliability in demanding manufacturing environments. The 3HAC14550-2/09A supports advanced motor control algorithms, enabling smooth acceleration/deceleration profiles and precise positioning for robotic arms across various industries.

The ABB 3HAC14550-2/09A is a high-performance servo drive module designed for ABB’s industrial robotics systems, specifically engineered to deliver precise motor control and dynamic motion feedback in robotic applications. As part of ABB’s 3HAC series of robotic control components, this servo drive belongs to the second-generation design, optimized for energy efficiency and reliability in demanding manufacturing environments. The 3HAC14550-2/09A supports advanced motor control algorithms, enabling smooth acceleration/deceleration profiles and precise positioning for robotic arms across various industries.

Compatible with ABB robot models such as the IRB 6700 and IRB 8700, this servo drive module features a compact, rack-mountable design that integrates seamlessly with ABB’s IRC5 controller system. It processes real-time feedback from position sensors (like the 3HAC0977-1) to adjust motor outputs, ensuring minimal tracking errors and vibration during high-speed operations. The ABB 3HAC14550-2/09A plays a critical role in enhancing robotic system productivity by enabling faster cycle times, reduced energy consumption, and improved repeatability.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3HAC14550-2/09A |

| Manufacturer | ABB |

| Product Type | Robotic Servo Drive Module |

| Power Rating | 9 kVA (continuous), 15 kVA (peak) |

| Input Voltage | 3-phase 380-480V AC ±10%, 50/60 Hz |

| Output Current | 12 A (continuous), 20 A (peak) |

| Control Technology | Field-oriented control (FOC) with vector control |

| Communication Ports | EtherNet/IP, Profinet, CANopen, RS-485 |

| Cooling Method | Forced air cooling (internal fan) |

| Operating Temperature | 0°C to +40°C (derating above 35°C) |

| Dimensions | 200 mm x 150 mm x 100 mm |

| Weight | 2.3 kg |

| Protection Class | IP20 (indoor use) |

| Compliance | CE, RoHS, ISO 13849 |

Main Features and Advantages

The ABB 3HAC14550-2/09A offers distinct advantages for robotic motion control: its 9 kVA power rating supports high-torque motors in heavy-duty applications, while field-oriented control (FOC) ensures smooth operation even at low speeds. The drive’s regenerative braking capability converts kinetic energy back to electrical power, reducing energy consumption by up to 30% compared to traditional drives.

The ABB 3HAC14550-2/09A offers distinct advantages for robotic motion control: its 9 kVA power rating supports high-torque motors in heavy-duty applications, while field-oriented control (FOC) ensures smooth operation even at low speeds. The drive’s regenerative braking capability converts kinetic energy back to electrical power, reducing energy consumption by up to 30% compared to traditional drives.

Reliability is enhanced through overvoltage/overcurrent protection and thermal monitoring, which prevent damage from transient faults. The hot-swappable design allows module replacement without system shutdown, minimizing downtime for maintenance. The drive’s EtherNet/IP and Profinet compatibility enables seamless integration with factory automation networks, while built-in diagnostic tools (via LED indicators and serial communication) simplify troubleshooting.

Compared to legacy servo drives, the 3HAC14550-2/09A features a 15% smaller footprint, optimizing space in control cabinets. Its modular construction allows parallel connection with other drives (e.g., 3HAC14551-2) for multi-axis robotic systems, enhancing scalability for complex setups.

Application Areas

The ABB 3HAC14550-2/09A is optimized for industrial robotics applications requiring precise motion control:

The ABB 3HAC14550-2/09A is optimized for industrial robotics applications requiring precise motion control:

- Automotive Body Welding: Drives robotic arms for high-speed, accurate welding of vehicle frames.

- Aerospace Component Handling: Enables gentle manipulation of large, delicate aircraft parts with sub-millimeter precision.

- Electronics Manufacturing: Controls pick-and-place robots for micro-component assembly in semiconductor production.

- Food Packaging: Drives robotic palletizers for high-speed, consistent product stacking in food and beverage facilities.

- Metal Forming: Powers heavy-duty robots for stamping, bending, and material removal in metalworking industries.

In each scenario, the drive’s energy efficiency and control precision contribute to reduced operational costs and improved product quality.

Related Products

- 3HAC031683-004 Cable 30M ABB DSQC679

- 3HAC031683-001

- ABB 3HAC026271-001 | ABB DSQC646

- ABB IRC5 Controller 3HAC025562-001 /06 Capacitor

- 3HAC025466-001 Bay Fan IRC5 REFURBISHED – ABB

- Abb 3HAB9271-1/01B Dummy Drive Unit

- Abb 3HAB8859-1/03A Dc Bus Bar Connecting Strip

- 3HAB8101-8/08Y ROBOTIC SERVO DRIVE

Installation and Maintenance

Installation Preparations:

Ensure the robotic system is powered off before installing the 3HAC14550-2/09A. Use the 3HAC14470-1 mounting bracket to secure the drive in a ventilated control cabinet, leaving at least 50 mm clearance for airflow. Connect the 3-phase power input (380-480V AC) using shielded cables, and terminate motor leads according to ABB’s wiring diagrams. Configure communication parameters via ABB’s RobotStudio software, assigning unique addresses for EtherNet/IP or Profinet networks.

Installation Preparations:

Ensure the robotic system is powered off before installing the 3HAC14550-2/09A. Use the 3HAC14470-1 mounting bracket to secure the drive in a ventilated control cabinet, leaving at least 50 mm clearance for airflow. Connect the 3-phase power input (380-480V AC) using shielded cables, and terminate motor leads according to ABB’s wiring diagrams. Configure communication parameters via ABB’s RobotStudio software, assigning unique addresses for EtherNet/IP or Profinet networks.

Maintenance Recommendations:

Regularly inspect the drive’s cooling fan for dust accumulation, cleaning or replacing it every 6 months to maintain optimal airflow. Monitor the drive’s operating temperature using RobotStudio, ensuring it does not exceed 40°C. Check cable connections for tightness and signs of wear, especially power and motor leads in high-vibration environments. Replace the drive if error codes (e.g., overvoltage or overheating) persist after troubleshooting, as this may indicate internal component failure. Periodic firmware updates (via ABB’s official channels) can enhance performance and add new features.

Regularly inspect the drive’s cooling fan for dust accumulation, cleaning or replacing it every 6 months to maintain optimal airflow. Monitor the drive’s operating temperature using RobotStudio, ensuring it does not exceed 40°C. Check cable connections for tightness and signs of wear, especially power and motor leads in high-vibration environments. Replace the drive if error codes (e.g., overvoltage or overheating) persist after troubleshooting, as this may indicate internal component failure. Periodic firmware updates (via ABB’s official channels) can enhance performance and add new features.

Product Assurance

The ABB 3HAC14550-2/09A is backed by a 1-year warranty, covering defects in materials and workmanship. ABB provides global technical support, including 24/7 remote assistance for configuration and troubleshooting. Authorized distributors maintain inventory of spare drives, ensuring 3-day delivery after payment to minimize production downtime. Rigorous testing (including load cycling, temperature stress, and electromagnetic compatibility) guarantees the 3HAC14550-2/09A meets ABB’s standards for industrial reliability and performance in mission-critical robotic applications.

The ABB 3HAC14550-2/09A is backed by a 1-year warranty, covering defects in materials and workmanship. ABB provides global technical support, including 24/7 remote assistance for configuration and troubleshooting. Authorized distributors maintain inventory of spare drives, ensuring 3-day delivery after payment to minimize production downtime. Rigorous testing (including load cycling, temperature stress, and electromagnetic compatibility) guarantees the 3HAC14550-2/09A meets ABB’s standards for industrial reliability and performance in mission-critical robotic applications.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com