Description

Product Overview

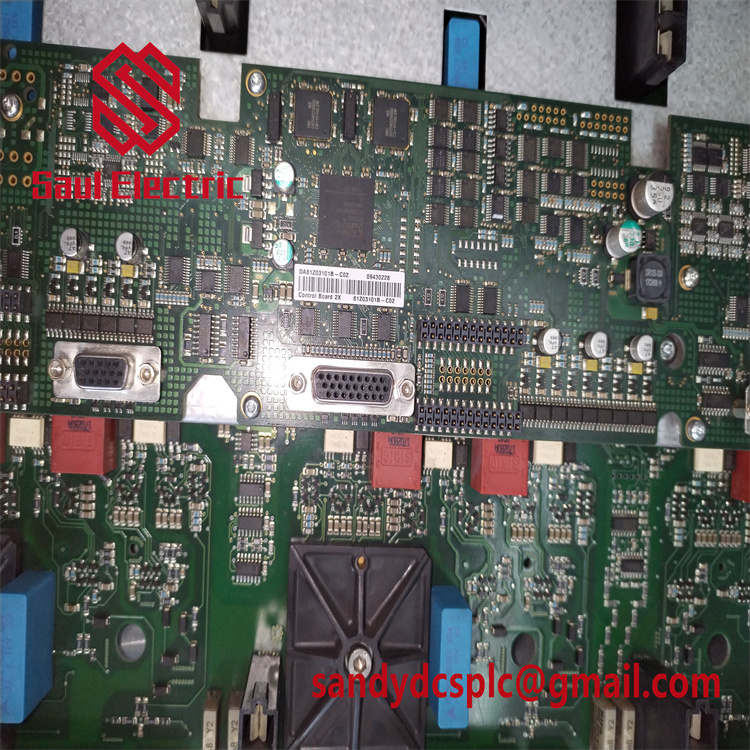

The ABB 3HAC10847-1 is a high-performance communication interface module designed for ABB’s IRC5 robotic controller system, engineered to enable seamless connectivity between industrial robots and external automation networks. As a critical component of ABB’s robotic ecosystem, this module belongs to the 3HAC series, specialized in providing robust communication solutions for complex manufacturing environments. The 3HAC10847-1 supports multiple industrial protocols, allowing real-time data exchange between robot controllers, PLCs, HMIs, and other factory automation devices.

The ABB 3HAC10847-1 is a high-performance communication interface module designed for ABB’s IRC5 robotic controller system, engineered to enable seamless connectivity between industrial robots and external automation networks. As a critical component of ABB’s robotic ecosystem, this module belongs to the 3HAC series, specialized in providing robust communication solutions for complex manufacturing environments. The 3HAC10847-1 supports multiple industrial protocols, allowing real-time data exchange between robot controllers, PLCs, HMIs, and other factory automation devices.

Designed to integrate with ABB robot models such as the IRB 6700 and IRB 8700, this interface module features a compact form factor that mounts directly onto the IRC5 controller chassis. It ensures reliable transmission of control signals, sensor data, and diagnostic information, enhancing system flexibility and productivity. The ABB 3HAC10847-1 plays a pivotal role in smart manufacturing setups, enabling robotic systems to communicate with enterprise networks for remote monitoring, predictive maintenance, and process optimization.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3HAC10847-1 |

| Manufacturer | ABB |

| Product Type | IRC5 Controller Communication Module |

| Supported Protocols | EtherNet/IP, Profinet, Modbus TCP, CANopen |

| Data Transfer Rate | Up to 1 Gbps (EtherNet/IP), 100 Mbps (Profinet) |

| Power Supply | 24V DC ±10% (150 mA typical) |

| Communication Ports | 2 x RJ45 (Ethernet), 1 x DB9 (serial), 1 x CANopen connector |

| Operating Temperature | 0°C to +50°C |

| Storage Temperature | -20°C to +70°C |

| Dimensions | 120 mm x 80 mm x 40 mm |

| Weight | 0.3 kg |

| Protection Class | IP20 (indoor use) |

| Compliance | CE, RoHS, ISO 13849 |

Main Features and Advantages

The ABB 3HAC10847-1 stands out for its multi-protocol compatibility, eliminating the need for separate gateways by supporting EtherNet/IP, Profinet, and other industrial standards. This reduces hardware complexity and integration costs in mixed-network environments. The module’s real-time data processing capability ensures minimal latency (≤1 ms), critical for synchronized robotic movements in high-speed production lines.

The ABB 3HAC10847-1 stands out for its multi-protocol compatibility, eliminating the need for separate gateways by supporting EtherNet/IP, Profinet, and other industrial standards. This reduces hardware complexity and integration costs in mixed-network environments. The module’s real-time data processing capability ensures minimal latency (≤1 ms), critical for synchronized robotic movements in high-speed production lines.

Reliability is enhanced through hot-swappable design, allowing module replacement without powering down the robot system, thus minimizing downtime. The built-in diagnostic LEDs provide instant visual feedback on network status and error conditions, simplifying troubleshooting. Compared to legacy interface modules, the 3HAC10847-1 offers upgraded cybersecurity features, including firmware encryption and access control, protecting against unauthorized network intrusion. Its low power consumption and fanless design also reduce maintenance needs in dusty or oily environments.

Application Areas

The ABB 3HAC10847-1 is optimized for industrial automation scenarios requiring seamless robotic communication:

The ABB 3HAC10847-1 is optimized for industrial automation scenarios requiring seamless robotic communication:

- Automotive Manufacturing: Connects welding robots to plant-wide EtherNet/IP networks for production data aggregation.

- Pharmaceutical Packaging: Enables Profinet-based communication between robotic dispensers and quality control systems in cleanrooms.

- Electronics Assembly: Facilitates high-speed data transfer between pick-and-place robots and PCB manufacturing lines via Modbus TCP.

- Food Processing: Integrates robotic palletizers with factory management systems using CANopen for real-time inventory updates.

- Aerospace Component Production: Supports secure communication between large-scale robotic arms and CNC machines in aircraft fabrication.

In each application, the module’s protocol flexibility and robust performance enable robots to function as smart, connected devices within Industry 4.0 ecosystems.

Related Products

- 3HAC031683-004 Cable 30M ABB DSQC679

- 3HAC031683-001

- ABB 3HAC026271-001 | ABB DSQC646

- ABB IRC5 Controller 3HAC025562-001 /06 Capacitor

- 3HAC025466-001 Bay Fan IRC5 REFURBISHED – ABB

- Abb 3HAB9271-1/01B Dummy Drive Unit

- Abb 3HAB8859-1/03A Dc Bus Bar Connecting Strip

- 3HAB8101-8/08Y ROBOTIC SERVO DRIVE

Installation and Maintenance

Installation Preparations:

Power off the IRC5 controller before installing the 3HAC10847-1. Use the 3HAC14470-1 mounting bracket to secure the module in an available slot on the controller chassis. Connect network cables to the RJ45 ports, ensuring proper strain relief. For Profinet or CANopen setups, use shielded cables and terminate connectors as per ABB guidelines. Configure protocols via ABB’s RobotStudio software, assigning unique IP addresses or device IDs to avoid network conflicts.

Installation Preparations:

Power off the IRC5 controller before installing the 3HAC10847-1. Use the 3HAC14470-1 mounting bracket to secure the module in an available slot on the controller chassis. Connect network cables to the RJ45 ports, ensuring proper strain relief. For Profinet or CANopen setups, use shielded cables and terminate connectors as per ABB guidelines. Configure protocols via ABB’s RobotStudio software, assigning unique IP addresses or device IDs to avoid network conflicts.

Maintenance Recommendations:

Regularly inspect the module’s status LEDs to confirm stable operation (green lights indicate normal function). Clean the ventilation slots with compressed air to prevent dust accumulation, which can cause overheating. Check network cables for fraying or loose connections, replacing damaged cables immediately. If communication errors occur, use RobotStudio’s diagnostic tools to identify protocol mismatches or hardware faults. Periodically update the module’s firmware through ABB’s official channels to access new features and security patches.

Regularly inspect the module’s status LEDs to confirm stable operation (green lights indicate normal function). Clean the ventilation slots with compressed air to prevent dust accumulation, which can cause overheating. Check network cables for fraying or loose connections, replacing damaged cables immediately. If communication errors occur, use RobotStudio’s diagnostic tools to identify protocol mismatches or hardware faults. Periodically update the module’s firmware through ABB’s official channels to access new features and security patches.

Product Assurance

The ABB 3HAC10847-1 is backed by a 1-year warranty, covering defects in materials and workmanship. ABB provides global technical support, including 24/7 remote assistance for configuration and troubleshooting. Authorized distributors maintain inventory of spare modules, ensuring 3-day delivery after payment to minimize production downtime. Rigorous testing (including temperature cycling, vibration resistance, and protocol compatibility) guarantees the 3HAC10847-1 meets ABB’s standards for industrial reliability and performance in mission-critical applications.

The ABB 3HAC10847-1 is backed by a 1-year warranty, covering defects in materials and workmanship. ABB provides global technical support, including 24/7 remote assistance for configuration and troubleshooting. Authorized distributors maintain inventory of spare modules, ensuring 3-day delivery after payment to minimize production downtime. Rigorous testing (including temperature cycling, vibration resistance, and protocol compatibility) guarantees the 3HAC10847-1 meets ABB’s standards for industrial reliability and performance in mission-critical applications.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com