Description

Product Overview

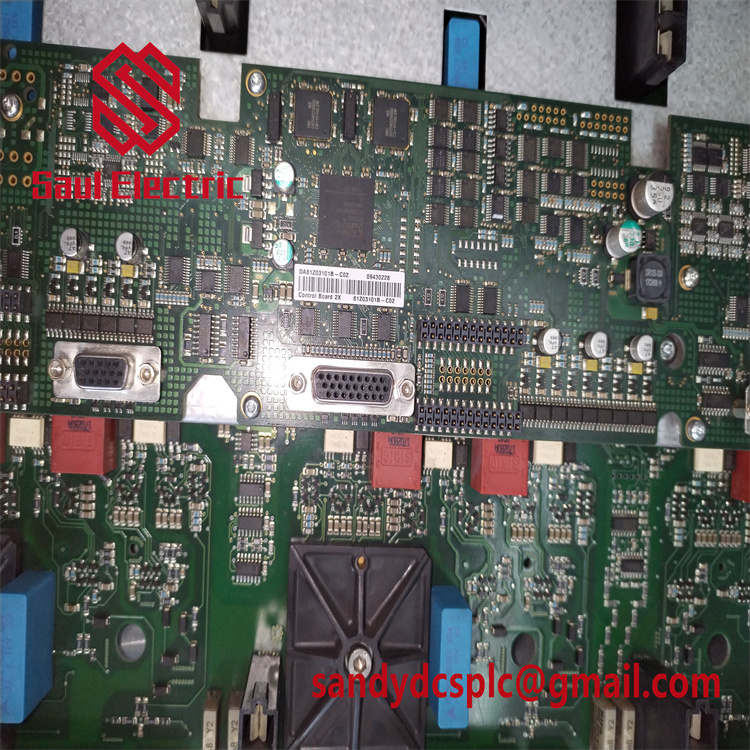

The ABB 3HAC025466-001 is a high-precision Robotic Arm Interface Module designed for ABB’s industrial robotic systems, specifically optimized for integration with the IRC5 controller platform and various robotic arm models. As part of ABB’s advanced robotics component portfolio, this module serves as a critical mechanical and electrical interface, enabling seamless coordination between robotic arms, servo drives, and control systems. Engineered for precision and durability, the 3HAC025466-001 ensures reliable motion control, signal transmission, and power distribution in automated manufacturing environments, making it essential for applications requiring sub-millimeter accuracy and repeatability.

Featuring a modular design and IP20-rated construction, the module withstands harsh industrial conditions, including vibrations, dust, and temperature fluctuations. It supports high-speed data exchange with robotic controllers via protocols like EtherNet/IP and CANopen, enabling real-time feedback for adaptive manufacturing processes. The 3HAC025466-001 integrates with ABB’s RobotStudio software for intuitive programming and diagnostics, simplifying system commissioning and maintenance. By bridging the gap between robotic hardware and control systems, this module enhances productivity in high-volume manufacturing lines while reducing downtime through its rugged reliability.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | ABB 3HAC025466-001 |

| Manufacturer | ABB |

| Product Type | Robotic Arm Interface Module |

| Compatibility | ABB IRC5 controllers, IRB series robots |

| Electrical Supply | 24 V DC ±10% |

| Communication Protocols | EtherNet/IP, CANopen, Modbus RTU |

| Mechanical Interface | Standard robotic arm mounting interface |

| Operating Temperature | 0°C to 50°C |

| Physical Dimensions | 180 mm (H) × 120 mm (W) × 60 mm (D) |

| Weight | 1.2 kg |

| Mounting Method | Direct mounting to robotic arm base |

| Certifications | CE, UL, ISO 13849-1 (Safety Category 3) |

Main Features and Advantages

The ABB 3HAC025466-001 delivers unmatched precision and system integration for robotic applications:

- High-Accuracy Motion Control: Enables robotic arms to achieve ±0.05 mm positioning accuracy, critical for tasks like semiconductor bonding and automotive welding.

- Modular Rugged Design: IP20-rated enclosure resists dust and light splashes, while shock/vibration resistance (50G peak) ensures reliability in harsh production environments.

- Multi-Protocol Connectivity: Supports real-time communication with PLCs, vision systems, and HMIs, eliminating the need for additional gateways in complex setups.

- Hot-Swap Capability: Field-replaceable without powering down the robot, reducing maintenance downtime by up to 40%.

- Integrated Diagnostics: Built-in LED indicators and error logging facilitate quick fault detection, with compatibility with ABB’s Condition Monitoring System for predictive maintenance.

- Energy-Efficient Design: Low-power consumption (≤20 W) minimizes operational costs while meeting strict energy efficiency standards.

Application Areas

The 3HAC025466-001 is pivotal in high-precision robotic automation across industries:

- Semiconductor Manufacturing: Controls robotic arms for wafer handling and micro-component assembly, ensuring contamination-free operations in cleanrooms.

- Automotive Industry: Enables precise welding, painting, and sealing in vehicle body manufacturing, integrating with vision systems for adaptive path correction.

- Electronics Assembly: Manages pick-and-place operations for SMT components on PCBs, supporting micro-LED display production and battery cell assembly.

- Medical Device Production: Powers robotic systems for syringe filling, catheter manufacturing, and lab automation, adhering to GMP standards.

- Aerospace Manufacturing: Facilitates robotic drilling and composite material layup for aircraft components, where tight tolerances are non-negotiable.

Related Products

- 3BUS208796-501 | ABB Power signal regulating Board

- ABB 3BSE076940R1 PM862K01 AC 800M CPU Board

- Abb 3BSE008538R1 I/O Module

- ONE NEW LWN1902-6E 3BHL000986P7001

- Abb 3BSE008538R1 I/O Module

Installation and Maintenance

Installation Preparation:

Before installing the ABB 3HAC025466-001, ensure the robotic arm base is properly grounded and free of debris. Verify the power supply (24 V DC) and use shielded cables for communication links to minimize EMI. Align the module’s mechanical interface with the robotic arm base, securing it with anti-vibration bolts. Configure network parameters via ABB RobotStudio, enabling EtherNet/IP for low-latency data transfer.

Before installing the ABB 3HAC025466-001, ensure the robotic arm base is properly grounded and free of debris. Verify the power supply (24 V DC) and use shielded cables for communication links to minimize EMI. Align the module’s mechanical interface with the robotic arm base, securing it with anti-vibration bolts. Configure network parameters via ABB RobotStudio, enabling EtherNet/IP for low-latency data transfer.

Maintenance Recommendations:

Conduct monthly inspections for loose connections or signs of wear, tightening bolts as needed. Clean the module’s vents with compressed air to prevent dust accumulation, especially in high-dust environments. Annually update firmware through RobotStudio to access the latest motion control algorithms and safety patches. For critical applications, perform quarterly functional tests using ABB’s diagnostic tools to ensure positional accuracy remains within specifications.

Conduct monthly inspections for loose connections or signs of wear, tightening bolts as needed. Clean the module’s vents with compressed air to prevent dust accumulation, especially in high-dust environments. Annually update firmware through RobotStudio to access the latest motion control algorithms and safety patches. For critical applications, perform quarterly functional tests using ABB’s diagnostic tools to ensure positional accuracy remains within specifications.

Product Guarantee

ABB provides a 1-year warranty for the 3HAC025466-001, covering defects in materials and workmanship. The module is supported by ABB’s 24/7 global robotics support team, offering remote diagnostics and on-site service when needed. Spare parts are available with 3-day delivery after payment, minimizing production interruptions. ABB’s RobotCare service agreement includes proactive maintenance, software updates, and lifecycle management, ensuring the module delivers optimal performance throughout its operational life in mission-critical applications.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com