Description

Product Overview

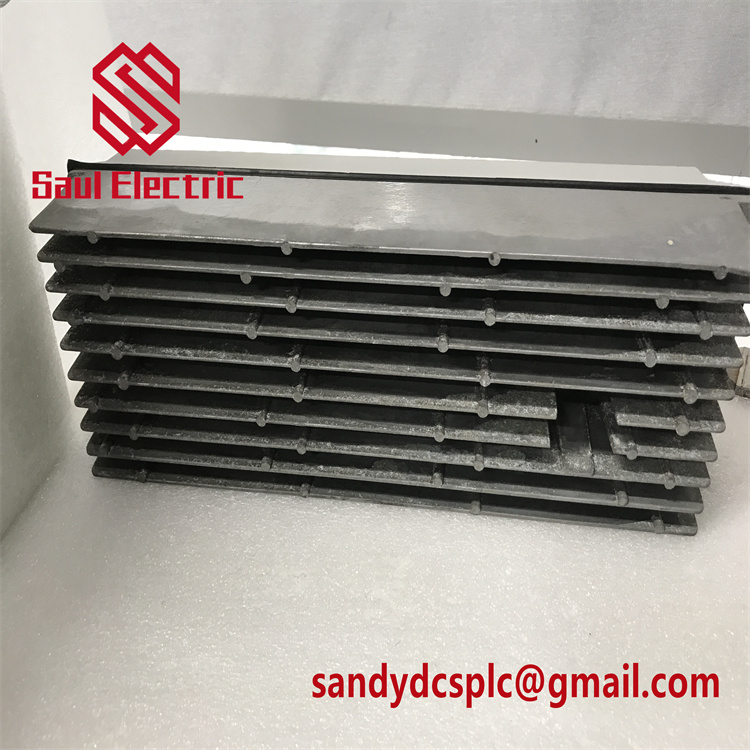

The ABB 3HAB8101-8/08Y is a high-reliability industrial automation component designed for ABB’s robotic systems, specifically tailored to integrate with advanced manufacturing setups. As part of ABB’s robust robotic accessory portfolio, this model serves as a critical interface or control module, enabling seamless communication and operational efficiency within robotic cells. Engineered to withstand rigorous industrial environments, the 3HAB8101-8/08Y facilitates precise motion control, signal processing, and system coordination, making it an essential component for applications requiring high precision and durability. Its design emphasizes compatibility with ABB’s IRC5 controller platform and other robotic peripherals, ensuring minimal downtime and optimized performance. This module plays a pivotal role in enhancing the flexibility and reliability of automated production lines, supporting industries from automotive manufacturing to electronics assembly.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3HAB8101-8/08Y |

| Manufacturer | ABB |

| Product Type | Robotic Interface Module/Control Unit |

| Electrical Supply | 24V DC ±10% |

| Operating Temperature | -10°C to +55°C |

| Communication Protocol | Industrial Ethernet, CANopen |

| Physical Dimensions | 150 mm x 100 mm x 50 mm (approx.) |

| Weight | 0.5 kg (approx.) |

| Mounting Type | Panel-mount or rack-mount |

| Protection Class | IP20 (indoor use) |

| Certification | CE, UL listed |

Main Features and Advantages

The ABB 3HAB8101-8/08Y stands out for its rugged construction and seamless integration capabilities within ABB’s robotic ecosystems. It offers advanced signal conditioning and real-time data processing, ensuring precise control over robotic movements and interactions with peripheral devices. One key advantage is its compatibility with multiple communication protocols, allowing flexible integration into diverse automation setups without extensive reconfiguration. The module’s diagnostic features enable quick fault detection, reducing maintenance downtime and enhancing overall system availability. Additionally, its compact design optimizes space in control cabinets, while the wide operating temperature range ensures reliable performance in challenging industrial environments. The 3HAB8101-8/08Y also adheres to strict industry standards for safety and durability, making it a trusted choice for mission-critical applications that demand consistent reliability.

Application Areas

The 3HAB8101-8/08Y is ideally suited for industrial robotic applications across various sectors. In automotive manufacturing, it supports robotic welding, painting, and assembly lines, ensuring precise motion control and system synchronization. In electronics production, the module facilitates delicate pick-and-place operations for component placement on PCBs, leveraging its high accuracy and repeatability. It is also applicable in logistics and material handling for robotic palletizing and sorting systems, where reliable interface connectivity is essential for efficient workflow. Furthermore, the module can be integrated into food and beverage processing lines for automated packaging and quality inspection, thanks to its compliance with hygiene standards and robust performance. Any industry relying on automated robotic systems to enhance productivity and precision can benefit from the 3HAB8101-8/08Y’s reliable functionality.

Related Products

- 3BUS208796-501 | ABB Power signal regulating Board

- ABB 3BSE076940R1 PM862K01 AC 800M CPU Board

- Abb 3BSE008538R1 I/O Module

- ONE NEW LWN1902-6E 3BHL000986P7001

- Abb 3BSE008538R1 I/O Module

Installation and Maintenance

Preparations before Installation: Ensure the installation environment meets the 3HAB8101-8/08Y’s operational specifications, including proper voltage supply and temperature range. Verify compatibility with the existing robotic system and prepare the mounting location (panel or rack) with appropriate grounding. Connect all cables according to the wiring diagram provided in the user manual to avoid signal interference.

Maintenance suggestions: Regularly inspect the module for physical damage or loose connections, especially in high-vibration environments. Clean the component with a dry, static-free cloth to prevent dust accumulation that could affect performance. Periodically update the firmware to incorporate the latest functionality and bug fixes, ensuring optimal compatibility with system updates. Maintain a record of operational parameters to identify any deviations from normal performance, which may indicate the need for servicing.

Product Guarantee

ABB stands behind the 3HAB8101-8/08Y with a comprehensive quality assurance commitment. The product includes a 1-year warranty covering manufacturing defects, ensuring peace of mind for customers. ABB’s global service network provides prompt technical support and 售后 assistance, helping to minimize downtime and resolve issues efficiently. Whether through remote diagnostics or on-site service, the company is dedicated to maintaining the reliability and performance of the 3HAB8101-8/08Y throughout its operational lifecycle, reflecting ABB’s legacy of excellence in industrial automation.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com