Description

Product Overview

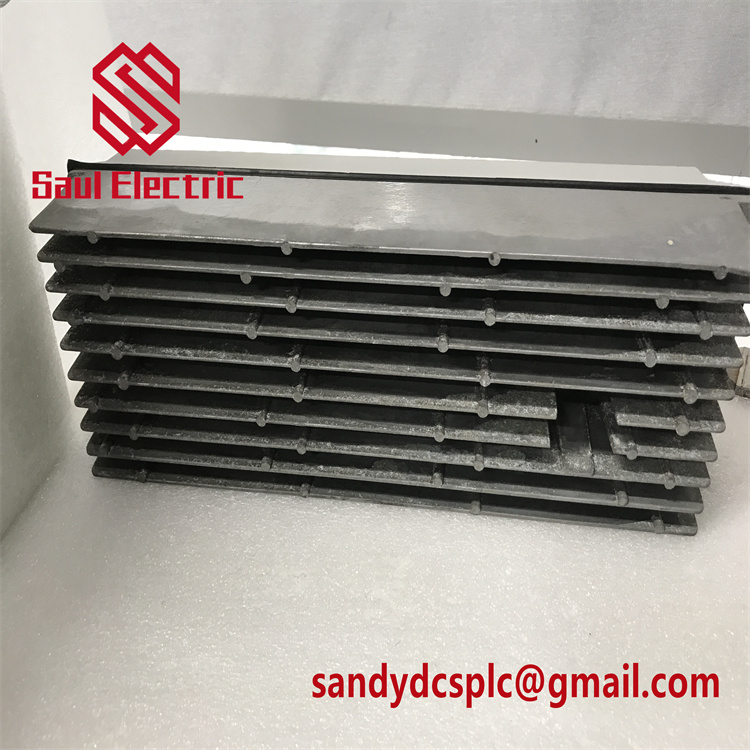

The ABB 3HAB3700-1 is a high-performance industrial control module designed for robotic automation systems, specifically tailored to integrate with ABB’s advanced robotic platforms. As a key component within ABB’s robotics portfolio, this module serves as a critical interface for managing motion control, signal processing, and system coordination in automated manufacturing environments. The ABB 3HAB3700-1 is engineered to ensure precise control and reliability, making it suitable for applications that demand high accuracy and repeatability. Belonging to ABB’s robotic controller series, the module enhances system efficiency by enabling seamless communication between robotic arms, sensors, and other peripheral devices. Its robust design withstands harsh industrial conditions, while its modular architecture supports easy integration and maintenance, positioning the 3HAB3700-1 as an essential component for optimizing production workflows in modern manufacturing setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 3HAB3700-1 |

| Manufacturer | ABB |

| Product Type | Robotic Control Module |

| Electrical Supply | 24 V DC ±10% |

| Communication Interfaces | Ethernet, RS-485, Digital I/O |

| Operating Temperature | 0°C to 50°C |

| Storage Temperature | -20°C to 70°C |

| Dimensions (L×W×H) | 150 mm × 100 mm × 50 mm |

| Weight | Approximately 0.8 kg |

| Protection Class | IP20 |

| Compatibility | ABB IRC5 robotic controllers and various robotic arm models |

| Mounting Method | Panel-mounted or rack-mounted |

Main Features and Advantages

The ABB 3HAB3700-1 stands out for its ability to deliver precise motion control and system synchronization, ensuring smooth operation of robotic systems in complex manufacturing processes. One of its key strengths is the high-speed processing capability, which allows real-time adjustment of robotic movements to meet tight tolerance requirements. The module’s flexible interface configuration supports multiple communication protocols, enabling seamless integration with diverse industrial networks and third-party devices. Additionally, its rugged construction ensures reliability in harsh environments, reducing downtime and maintenance costs. The 3HAB3700-1 also features the latest diagnostic tools, allowing quick fault detection and troubleshooting, which enhances overall system availability. ABB’s focus on energy efficiency is evident in this module, as it optimizes power consumption without compromising performance, making it an eco-friendly choice for sustainable manufacturing.

Application Areas

The ABB 3HAB3700-1 is widely applied in industries requiring automated robotic operations, such as automotive manufacturing, electronics assembly, food and beverage packaging, and pharmaceutical production. In automotive plants, the module supports robotic welding, painting, and material handling, ensuring precision and consistency in repetitive tasks. For electronics manufacturers, it enables delicate assembly processes for components like semiconductors and circuit boards, where micro-level accuracy is essential. The module’s adaptability also makes it suitable for logistics and warehousing, where it coordinates robotic palletizing and sorting systems. Furthermore, in industries with strict hygiene standards, such as food and pharmaceuticals, the 3HAB3700-1’s durable and easy-to-clean design meets regulatory requirements. Its versatility allows integration into both new automation setups and retrofitted systems, making it a valuable asset for upgrading industrial processes.

Related Products

- 3BUS208796-501 | ABB Power signal regulating Board

- ABB 3BSE076940R1 PM862K01 AC 800M CPU Board

- Abb 3BSE008538R1 I/O Module

- ONE NEW LWN1902-6E 3BHL000986P7001

- Abb 3BSE008538R1 I/O Module

Installation and Maintenance

Preparations before Installation: Before installing the ABB 3HAB3700-1, ensure the mounting surface is stable and free from vibrations. Verify that the electrical supply matches the module’s specifications (24 V DC) and that all communication cables are properly shielded to prevent interference. It is essential to power off the entire system and follow ESD (electrostatic discharge) precautions to avoid damage to the module.

Maintenance suggestions: Regular maintenance of the 3HAB3700-1 includes periodic visual inspections for loose connections or physical damage. Clean the module’s exterior with a dry, lint-free cloth to remove dust and debris, especially in dusty environments. Monitor the module’s operational temperature and ensure proper ventilation to prevent overheating. ABB recommends scheduling annual system diagnostics using the built-in monitoring tools to detect potential issues early, ensuring optimal performance and longevity.

Product Guarantee

ABB stands behind the 3HAB3700-1 with a comprehensive quality assurance program, offering a standard 1-year warranty against manufacturing defects. The company provides global technical support and 售后服务,ensuring prompt assistance for installation, troubleshooting, and maintenance. ABB’s network of authorized service centers and certified technicians guarantees that customers receive professional support throughout the product’s lifecycle. This commitment to quality and reliability makes the 3HAB3700-1 a trusted choice for critical industrial applications, with peace of mind ensured by ABB’s decades of expertise in automation technology.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com