Description

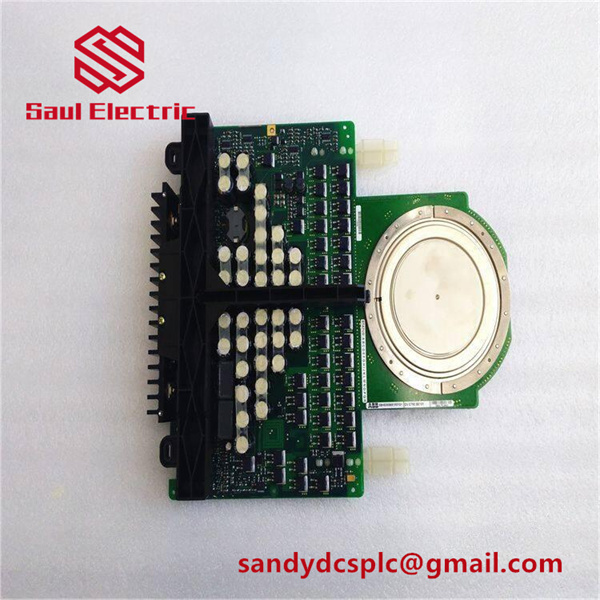

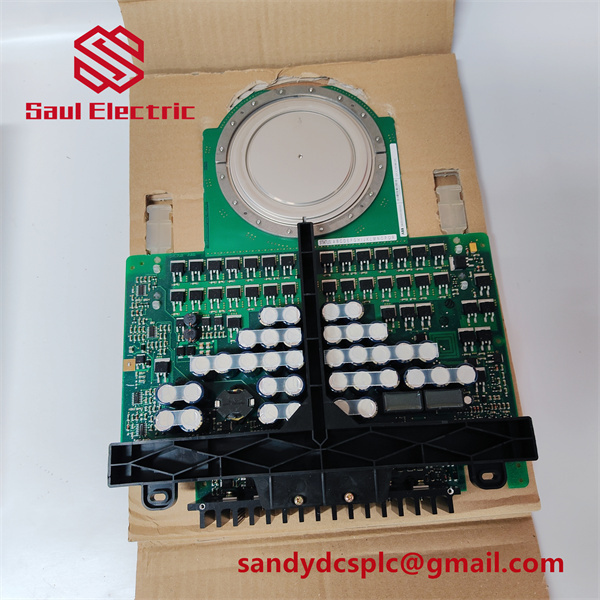

ABB 5SGY3545L0009/5SHY3545L0009 IGCT Power Module – Product Details

Product Overview

In the field of megawatt-level power control, the ABB 5SGY3545L0009 (also commonly labeled as 5SHY3545L0009) stands as an absolute core player. This high-performance Asymmetric Integrated Gate-Commutated Thyristor (IGCT) power module serves as the heart of ABB’s ACS6000 series medium-voltage drive systems, built specifically for the most demanding heavy industrial applications.

It innovatively adopts a groundbreaking asymmetric structure and press-pack technology, highly integrating GTO chips with anti-parallel diodes and gate drive circuits. This design perfectly combines the low conduction loss of thyristors with the stable turn-off capability of transistors. When conducting, it demonstrates the efficiency of a thyristor; when turning off, it provides the precise control of a transistor—this dual advantage makes it stand out in high-power electrical control and conversion applications.

As a culmination of ABB’s power semiconductor technology, this IGCT module plays a critical role in megawatt-level power drive and conversion systems across industries such as steel, mining, marine propulsion, and energy. Its ultra-high insulation voltage and on-state current density allow it to effortlessly handle complex operating conditions involving high voltage, high frequency, and high current. Even in the most extreme industrial environments, it consistently delivers stable, reliable, and efficient power conversion to ensure optimal system performance.

Core Specifications

| Core Parameters | Specific Specifications |

|---|---|

| Product Model | ABB 5SGY3545L0009 / 5SHY3545L0009 |

| Manufacturer | ABB (ASEA BROWN BOVERI) |

| Product Type | Asymmetric Integrated Gate-Commutated Thyristor (IGCT) Power Module |

| Rated Voltage (Repetitive Peak) | 4500V — Exceptional high-voltage tolerance for industrial high-voltage scenarios |

| Rated Current (Max RMS) | 4000A — Ultra-high current capacity to meet megawatt-level equipment demands |

| Maximum Switching Frequency | 500Hz |

| Switching Loss | < 2.5 kW per device — Low-loss design reduces energy consumption and cooling pressure |

| Turn-off Time | < 3 µs — Ultra-fast response for millisecond-level precision control |

| Cooling Method | Deionized water cooling (ΔT=35°C) — Efficient heat dissipation for stable operation |

| Isolation Level | 12 kV AC (between main terminals) — Superior insulation ensures operational safety |

| Gate Drive Unit | GVC750BE101 (fiber-optic isolated) — Strong anti-interference capability for stable signal transmission |

| Operating Temperature (Junction) | 0°C to +125°C — Wide temperature range for reliable operation in harsh environments |

| Protection Rating (Body) | IP4X — Dust-proof design suitable for dusty industrial environments |

| Dimensions (Approx.) | Power stack assembly: 450mm × 300mm × 150mm; Module itself: 439mm × 173mm × 41mm |

| Weight (Approx.) | 2.9 kg (module itself) — Lightweight design for easier installation and maintenance |

Key Features & Advantages

One of the core advantages that makes this IGCT module a leader in high-power control is its ultra-fast switching capability. Even at high currents of 4000 Amperes, it achieves turn-off times of less than 3 microseconds, eliminating the need for snubber circuits required by conventional GTOs. This not only simplifies system design but also significantly improves reliability—who wouldn’t appreciate a design that reduces both costs and potential failure points?

When paired with the dedicated GVC750BE101 gate driver, it achieves 15kV/µs immunity, delivering clean PWM waveforms. For precision applications sensitive to harmonics, isn’t this the ideal solution?

High reliability and fault-tolerant design are its true strengths. Using press-pack technology, gold-plated copper busbars and spring-loaded pressure contacts can withstand up to 100,000 thermal cycles, significantly extending service life. Dual-redundant gate drivers with cross-monitoring maintain output even if a single driver fails.

Even more impressive is the fault tolerance of the press-pack design—with up to 5% failed chips, it can continue operation through current redistribution, dramatically improving system availability. Its asymmetric structure inherently provides higher reliability and lower leakage current, giving operators peace of mind.

Predictive maintenance capabilities add another layer of intelligence. Through fiber Bragg grating sensors on the 3BHB013085R0001 interface board, junction temperature gradients can be monitored with an accuracy of ±1.5°C. Integrated with the ABB Ability™ analytics platform, this enables AI-based performance degradation prediction, facilitating proactive maintenance scheduling and significantly reducing unplanned downtime. For industrial operations where downtime can cost millions per hour, this delivers tangible value.

Application Fields

In high-torque applications requiring megawatt-scale control, this IGCT module has few competitors. In the steel industry, it drives rolling mill synchronous motors up to 10,000 HP for reversing stands, providing speed regulation better than 0.25%—this translates to unparalleled precision in steel production.

In cement manufacturing, its rugged design is perfectly suited for kiln drives operating in limestone dust environments. In marine propulsion, its compact power density enables azimuth thrusters exceeding 20 MW while maintaining IGBT-like switching precision.

Mining belt conveyors benefit from its regenerative braking capability, recovering up to 35% of energy during downhill ore transport—resulting in substantial electricity cost savings for mining operations. It’s also widely used in power transmission, conversion, and control equipment such as high-voltage frequency converters and power regulators.

Even compressors in the petrochemical industry rely on its SIL 2 safety certification for critical anti-surge controls—providing the reliability required in safety-critical chemical production environments.

Related Products

- 5SHY5045L0004: 5.2kV IGCT device designed for higher voltage applications

- 3BHE039203R0101: Liquid cooling unit specifically engineered for the 5SGY3545L0009 power stack

- GVC750CE101: Enhanced gate drive unit with HVDC support

- 5SDF0860H0003: Clamping circuit module for use with IGCTs

- 3BHB007209R0001: Fiber-optic receiver board for signal transmission

- ACS6000 Control Unit: Master controller for coordinating multiple power stacks

- 5SXE08-0181: Replacement water manifold kit

Installation & Maintenance Guidelines

Pre-Installation Preparation

Before installing the power stack, don’t rush—proper preparation is key. Cooling water resistivity must exceed 1MΩ-cm, and flow rate should be greater than 25L/min per stack to ensure effective heat dissipation. Before energizing, be sure to pre-charge DC bus capacitors using ABB’s dedicated charging unit to prevent component damage. Additionally, calibrate fiber-optic receivers using the DTCE tool to ensure accurate signal transmission.

Installation Guidelines

This module is typically designed for vertical installation, compatible with GGD, KYN series high-voltage switchgear. During installation, ensure gold-plated copper busbar connections are secure, and spring pressure contact force remains within specified ranges (e.g., 800N ±5% tolerance). This ensures optimal electrical contact and heat dissipation—after all, poor connections not only affect performance but can also pose safety risks.

Maintenance Recommendations

Proper maintenance is essential for long-term stable operation. Perform quarterly cooling water quality analysis, maintaining pH between 6.5-8.0. Conduct annual thermal imaging inspections of busbar joints to identify potential hot spots. Replace gate driver capacitors after 50,000 hours of operation. After 10 years of service, verify pressure contact force remains within allowable tolerances to ensure consistent performance.

Product Warranty & Support

ABB stands firmly behind the quality of the 5SGY3545L0009 IGCT power module. Featuring a ceramic-metal hermetic housing, it effectively prevents coolant contamination in humid environments, ensuring long service life and stable operation. Under full load cycles, it boasts a design life of up to 50 years with a Mean Time Between Failures (MTBF) exceeding 300,000 hours.

This level of reliability is particularly critical for critical production processes where unplanned downtime can cost millions of dollars per hour. All products comply with relevant international standards (such as IEC) and safety certifications (such as CE), backed by ABB’s professional technical support and comprehensive after-sales service to provide complete peace of mind for users.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com