Description

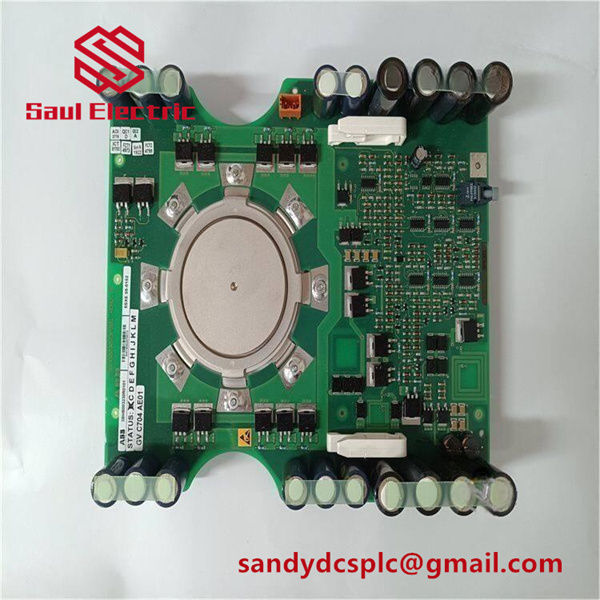

ABB 5SHX26L4510 Reverse Conducting Integrated Gate-Commutated Thyristor Product Description

Product Overview

Truth be told, the ABB 5SHX26L4510 – a high-power reverse conducting integrated gate-commutated thyristor (IGCT) – stands as a core player in ABB’s premium IGCT lineup. It adopts a reverse conduction design, cleverly blending the low on-state loss advantage of thyristors with the flexible switching capability of fully controlled transistors, making it particularly popular in high-power, high-frequency industrial power electronics scenarios. As a key member of the ABB 5SHX series, it delivers impressive performance in medium-voltage applications – its compact modular structure paired with a robust build ensures stable long-term operation even in harsh industrial environments.

In the power conversion and control links of automation systems, this IGCT acts as a “backbone.” You’ll find it in critical equipment like high-power frequency converters, AC speed regulation systems, and flexible AC transmission devices. Its value goes beyond expectations: it not only significantly reduces system switching losses and boosts overall efficiency but also simplifies snubber circuit design, trimming both system size and cost. Compared to traditional GTO thyristors, it offers faster switching speeds, higher reliability, and simpler drive requirements – isn’t this exactly the high-power switching solution modern industrial power electronics equipment crave?

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 5SHX26L4510 |

| Manufacturer | ABB |

| Product Type | Reverse Conducting Integrated Gate-Commutated Thyristor |

| Repetitive Peak Off-state Voltage VDRM | 4500V |

| Maximum Turn-off Current | 1010A |

| On-state Current IT(RMS) | Determined by actual application conditions |

| Repetitive Peak Reverse Voltage VRRM | 4500V |

| Maximum Gate Trigger Voltage | Standard IGCT drive level |

| Typical On-state Voltage Drop | Low conduction loss design |

| Operating Junction Temperature Range | -40°C to +125°C |

| Mounting Method | Modular mounting, compatible with standard heat sinks |

| Package Type | Press-fit module, excellent thermal and insulation performance |

| Weight | Approximately 1kg (varies by specific configuration) |

Key Features and Advantages

The ABB 5SHX26L4510 IGCT packs numerous innovative technical highlights, bringing substantial operational benefits to users. Its switching performance is truly remarkable – it can operate stably at higher frequencies while keeping switching losses extremely low. Isn’t this the key to directly improving system efficiency and reducing operating costs? The module features a die-cast powder-coated aluminum housing, offering robust mechanical protection. Even in humid, dusty harsh industrial environments, it performs reliably, maintaining stable operation at temperatures between -10°C and +60°C with 85% humidity.

In fact, it adopts an open architecture design based on .NET framework technology, supporting compatibility with multi-vendor controllers and greatly enhancing system integration flexibility. Moreover, the device’s drive circuit is relatively simple, eliminating the need for complex snubber circuits – this not only cuts system costs but also improves overall reliability. Its vector-based high-resolution graphic control interface is highly user-friendly, simplifying operation and monitoring, and enabling engineers to complete commissioning and maintenance efficiently. These features make the 5SHX26L4510 an ideal choice for high-power industrial applications, especially excelling in space-constrained environments or scenarios with strict efficiency requirements.

Application Areas

From heavy industry to the power sector, this device is widely used in power conversion and control scenarios across various industrial fields. In heavy industry, it is particularly suitable for high-power motor drives, main drives for rolling mills, mine hoists, and frequency conversion speed regulation systems for large fans and pumps – on these devices, it consistently delivers efficient and reliable power control solutions. In the power industry, it is indispensable for critical equipment such as static VAR compensators, flexible AC transmission systems, and converter valves for high-voltage direct current transmission, significantly improving grid stability and power quality.

In the process industry, the 5SHX26L4510 plays an equally irreplaceable role. It supports key equipment like large compressor unit drives in the petrochemical industry, high-power pump installations, and blast furnace blowers in the metallurgical industry. You might not expect it, but it also shines in renewable energy fields – for example, grid-connected converters in large wind power generation systems and multilevel converter topologies in industrial drive systems. In industries such as papermaking, metal processing, and mining, it has long been the preferred power semiconductor device due to its excellent reliability and efficiency, perfectly meeting the strict requirements for continuous operation and high performance in these sectors.

Related Products

- 5SHY35L4510: Asymmetric IGCT, compatible with voltage source inverter topologies

- 5SHX14H4510: Medium-power IGCT in the same series, rated 420A/4500V, suitable for medium-power applications

- 5SHX10H6010: High-voltage version IGCT, compatible with 5500V voltage level scenarios

- 5SHX19L6010: High-power IGCT, rated 840A/5500V, suitable for higher power density systems

- 5SHY55L4500: High-current IGCT, rated current 1860A, suitable for ultra-high power applications

- 5SHY42L6500: High-voltage IGCT, rated voltage 6500V, suitable for high-voltage systems

- 5SHX08F4510: Low-power IGCT, rated 250A/4500V, suitable for low-power systems

- 5SHX06F6010: High-voltage medium-power IGCT, meeting special application requirements

Installation and Maintenance

Installation Preparation

Before installing the ABB 5SHX26L4510, first check that the module’s appearance is intact and the heat dissipation surface is flat and clean. Select a suitable heat sink and apply compatible thermal grease to ensure good thermal contact. When tightening the mounting bolts, use the specified torque and apply force evenly – otherwise, local stress concentration may damage the chip, a pitfall many engineers have encountered. For electrical connections, use cables with the recommended cross-sectional area, and ensure the terminals are clean and secure to reduce contact resistance and thermal stress.

Maintenance Recommendations

Regularly check if the device’s electrical connections are loose, and monitor the operation status of the cooling system. During equipment shutdown for maintenance, clean dust and debris from the module surface and inspect the cooling fans. Keep an eye on the module’s operating temperature to ensure it does not exceed the specified junction temperature range. If the system operates abnormally, it is advisable to use professional equipment to test the IGCT’s switching characteristic parameters and identify potential issues early. Keep the drive circuit board clean and dry to avoid device damage caused by abnormal drive signals.

Product Assurance

ABB provides comprehensive quality assurance and professional technical support for the 5SHX26L4510. All factory products undergo rigorous layers of testing and inspection to meet ABB’s high-quality standards. We offer a one-year warranty – during the warranty period, free repair or replacement is available for any material or workmanship defects.

Customers also receive full-range technical support, including application consulting, installation guidance, and fault diagnosis, assisted by professional personnel. Our product supply chain is stable and reliable, ensuring genuine products and timely response to customer orders. For the 5SHX26L4510, we also provide detailed technical documentation and application notes to help customers fully leverage the product’s performance. Relying on ABB’s global service network, we can offer customers responsive after-sales service, ensuring stable equipment operation and minimizing unplanned downtime.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com