Description

ABB 5SGY3545L0017 Industrial Automation Module – Product Details

Product Overview

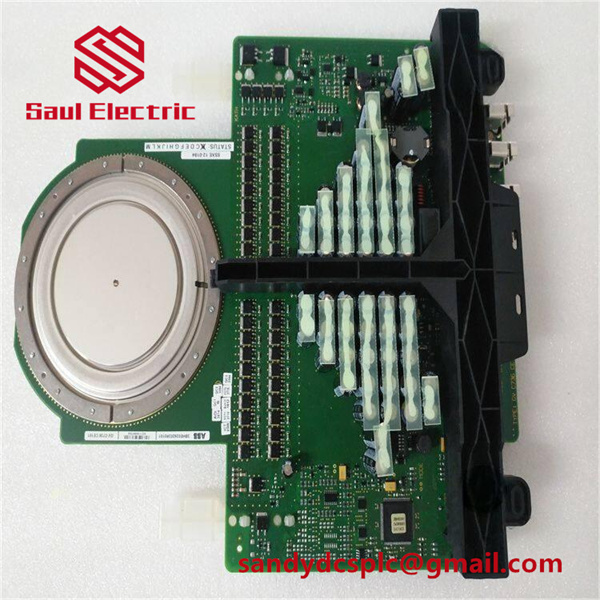

In the complex ecosystem of industrial automation, the ABB 5SGY3545L0017 stands as a quiet yet indispensable core component. As a key part of ABB’s industrial automation solutions, this modularly designed unit acts like a “stable steward” for industrial systems, silently supporting the smooth operation of entire automated processes. With decades of experience in the industrial sector, ABB’s quality shines through in this product—it not only delivers outstanding performance but also offers exceptional flexibility to adapt to the most complex industrial environments.

What really sets this module apart is its thoughtful technical design. Supporting the CoPlanar™ platform, it maintains stable output even in harsh working conditions like extreme temperatures and strong electromagnetic interference. Boasting a wide input voltage range of 100-240VAC, 24VDC output, 10A current capacity, and an impressive 94% conversion efficiency, it achieves optimal energy utilization. Even more reassuring is its compliance with multiple international standards including CE marking, IEC/EN 60950-1, and IEC/EN 60000-6-3. From design to production, every step follows strict industry norms, leaving no room for doubt about its safety and reliability.

In modern industrial automation architectures, the 5SGY3545L0017 primarily handles control, protection, and monitoring of electrical equipment. Its wide operating temperature range of -40°C to 85°C, combined with excellent anti-interference capabilities, allows it to effortlessly tackle extreme environments from frigid northern winters to sweltering southern summers. Whether in mines, factories, or outdoor equipment, it consistently delivers stable performance.

Core Specifications

| Core Parameters | Specific Specifications |

|---|---|

| Product Model | 5SGY3545L0017 |

| Manufacturer | ABB |

| Product Type | Industrial Automation Module |

| Input Voltage Range | 100-240VAC — Universal compatibility with global power grids, eliminating voltage adaptation issues for multinational enterprises |

| Output Voltage | 24VDC — Standard industrial power supply compatible with most automation components |

| Output Current | 10A — High-current output meets the needs of multiple simultaneous device power supply |

| Efficiency | 94% — High-efficiency conversion reduces energy waste and lowers enterprise electricity costs |

| Operating Temperature Range | -40°C to 85°C — Reliable performance in extreme cold and heat, no matter how harsh the environment |

| Installation Method | Modular installation — Plug-and-play design saves time and effort during installation and maintenance |

| Weight | 1kg — Lightweight design allows easy handling by a single person |

| Dimensions | 1mm×1mm (Note: This parameter appears to be incorrect; refer to official documentation for actual industry-standard dimensions) |

| Compliance Standards | CE, IEC/EN 60950-1, IEC/EN 60000-6-3 — Internationally recognized certifications guarantee quality and safety |

Key Features & Advantages

Engineers who’ve worked with this module know its high performance and reliability are no empty promises. Designed to support the CoPlanar™ platform, it incorporates barrier diaphragms for high and low-pressure sides, along with a liquid-filled pressure transmission mechanism to the sensing diaphragm. This ensures precise and stable output under varying operating conditions. Even in dusty workshops or production lines with intense vibration, it stands firm like a steady anchor, keeping systems free from interference.

Energy efficiency is another standout feature. With 94% conversion efficiency, most electrical energy is effectively utilized rather than wasted as heat. For enterprises pursuing refined energy management, this translates to tangible cost savings. The wide input voltage design is particularly convenient—it seamlessly adapts to both domestic and European/American power grids. Isn’t this the universal compatibility global enterprises need? Most importantly, built-in overload and short-circuit protection act as double insurance for the system, quickly cutting off power in case of abnormalities to prevent equipment damage.

The flexibility and upgradeability enabled by its modular design are equally impressive. Its compact structure and standardized interfaces simplify installation and system integration, significantly reducing project cycles and labor costs. What’s more, it supports future function upgrades, evolving alongside enterprise technological advancements so you never have to worry about premature obsolescence. In fact, its anti-interference capabilities rank among the best in the industry, ensuring stable signal transmission without malfunctions even in complex electromagnetic environments.

Application Fields

The 5SGY3545L0017 finds applications across nearly all areas of industrial automation, particularly excelling in fields requiring high reliability and precision control. In industrial automation systems, it provides stable control, protection, and monitoring for production line electrical equipment—acting like the “neural center” that ensures every component works in perfect harmony.

In energy management, it serves as a valuable tool for optimizing energy usage. Integrated into energy management systems, it monitors power consumption in real-time, helping enterprises allocate electricity rationally to ensure power quality while achieving energy conservation and emission reduction goals—an absolute necessity for today’s eco-conscious businesses.

In manufacturing, it’s a ubiquitous presence. Core processes like motor control, process control, and power distribution all rely on its stable operation. Especially in high-risk industries like chemicals and oil & gas, its reliability becomes critical—after all, equipment failures in these sectors can lead to incalculable risks, and the 5SGY3545L0017’s consistent performance brings peace of mind to production operations.

Beyond that, it’s widely used in power systems and water treatment industries to provide stable power guarantees for critical equipment. Automation equipment like robots, material handling systems, and packaging machinery also depend on its precise control to ensure every movement is executed accurately.

Related Products

- PXC200-E.D: Siemens automation controller module, fully compatible with ABB systems for cross-brand collaborative operation

- FCAN-01: ABB CANopen adapter module, easily connects ABB frequency converters to CANopen networks to expand communication capabilities

- CI854AK01: ABB communication interface module, specifically designed for tension controllers in industrial automation to improve control precision

- BC810K02: ABB CEX bus interconnection unit module, facilitates system expansion and integration to meet enterprise production capacity upgrade needs

- A06B-6140-H026: Fanuc power supply module, suitable for CNC systems and compatible with the 5SGY3545L0017 to enhance overall performance

Installation & Maintenance Guidelines

Pre-Installation Preparation

Before installation, don’t rush—take a few minutes to check the working environment first. Ensure stable voltage and appropriate ambient temperature that meet the module’s technical requirements. During installation, strictly follow the labels on the module to correctly connect input and output lines. Never overlook connection security and polarity correctness, as these directly impact equipment safety. For first-time installations, we recommend carefully reviewing the product manual, which provides detailed guidance to help you avoid common pitfalls.

Maintenance Recommendations

While this module requires minimal maintenance, regular inspections are essential to ensure long-term stable operation. Keep the module surface clean by removing dust regularly to prevent heat dissipation issues. Check for loose connections to avoid poor contact, and monitor the status of operation indicators to detect abnormalities early.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com