Description

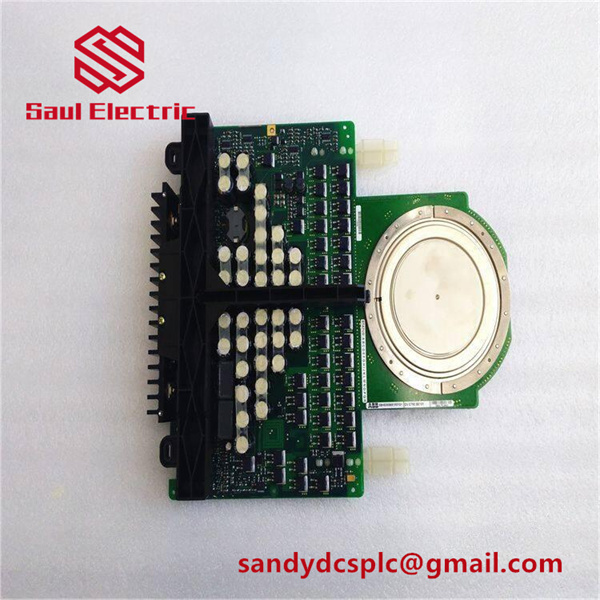

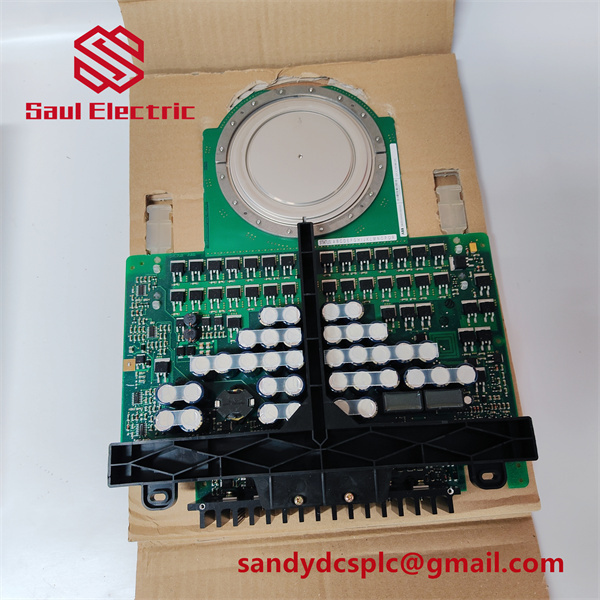

ABB 5SGY3545L0008 Industrial Automation Module – Product Details

Product Overview

Part of ABB’s high-end 5SGY series, the 5SGY3545L0008 stands out as a versatile powerhouse in industrial automation. Built with a modular design philosophy, it’s tailor-made for complex industrial automation systems—acting like the “nerve center” of industrial equipment, quietly underpinning the stable operation of entire systems in critical scenarios such as turbine control, DCS systems, robotic systems, and large-scale servo control systems.

Any engineer who’s spent time on the factory floor knows ABB’s decades of expertise in industrial automation shine through in this module. Its highly integrated design paired with reliable performance delivers impressive control precision and system stability. As a key member of ABB’s automation product lineup, it doesn’t just excel at core tasks like signal processing, data exchange, and equipment control—it also supports multiple industrial communication protocols, seamlessly integrating into existing enterprise automation architectures. For businesses embarking on digital transformation, isn’t this the most hassle-free technical support?

The benefits of modular design extend far beyond integration. Installation and maintenance require no major overhauls, and flexible expansion configurations adapt to industrial applications of all sizes—from small production lines to large factories, it finds its place everywhere.

Core Specifications

| Core Parameters | Specific Specifications |

|---|---|

| Product Model | ABB 5SGY3545L0008 |

| Manufacturer | ABB |

| Product Type | Industrial Automation Control Module |

| Rated Voltage | 208-480V AC (compatible with 24V DC) — Wide voltage adaptability handles voltage fluctuations in older workshops with ease |

| Rated Current | 45A |

| Output Frequency | 0-400Hz |

| Operating Temperature Range | -40℃ to +85℃ — Tackles harsh industrial environments, from freezing cold to sweltering heat |

| Protection Rating | IP45 — Dust and water resistance meets the needs of most industrial settings |

| Communication Protocols | Supports mainstream protocols including Modbus, Profibus, EtherCAT |

| I/O Points | Expandable up to 128 points — Expansion potential accommodates future production capacity upgrades |

| Program Capacity | 50,000 steps |

| Data Capacity | 100KB |

| Dimensions | 120mm x 120mm x 120mm (estimated) — Compact design saves installation space |

| Mounting Method | DIN rail mounting — Industry-standard installation fits most control cabinets |

Key Features & Advantages

The 5SGY3545L0008’s success in industrial settings isn’t just about paper specifications—it’s the perfect blend of high performance and reliability that makes it a standout. Featuring advanced power density design and rigorously selected industrial-grade components, it remains rock-solid even in -40℃ cold workshops or 85℃ high-temperature engine rooms.

Its low-noise, high-efficiency design acts like an “energy-saving heart” for systems—boosting energy utilization, cutting electricity costs, and reducing replacement frequency through its long-life design. Who wouldn’t love equipment that’s both reliable and cost-effective?

Modular design and flexible expandability are further selling points. It works seamlessly with MACH-ProPoint expansion modules (such as MMP-Io, MMP-I), supporting up to 128 I/O points. Whether it’s a small production line or a large integrated system, it adapts effortlessly. Better yet, built-in protection mechanisms and fault diagnosis functions simplify installation and integration, while minimizing maintenance headaches—engineers no longer need to stress over troubleshooting.

In scenarios demanding precise control, this module truly shines. Equipped with advanced control algorithms, it boasts fast processing speeds and short response times, controlling motor speed and torque with millimeter-level precision. This translates to more stable production processes and consistent product quality—exactly what businesses need to stay competitive in lean manufacturing.

Application Fields

Amid the wave of smart manufacturing, the 5SGY3545L0008 is a true all-rounder. In DCS distributed control systems, it serves as the “traffic hub” for data transmission; in robotic integration systems, it acts as the “neural center” for precise execution; in large servo control systems, it becomes the “ballast stone” for stable operation. It easily meets the high demands for control precision and reliability in complex industrial scenarios.

It’s also a mainstay in energy management. Critical infrastructure like power station monitoring systems, power plant control systems, and intelligent fire-fighting water supply systems rely on its high reliability and stability to ensure safe operation. What’s more, its communication capabilities enable real-time energy data collection and analysis, optimizing energy distribution and boosting efficiency.

Manufacturing is its primary “battleground.” Industries including food processing, material handling, HVAC, textile machinery, printing equipment, rubber and plastic processing, and woodworking machinery all benefit from its presence. By precisely controlling production processes, it not only improves efficiency and product quality consistency but also reduces energy consumption and maintenance costs—key competitive advantages in today’s fierce market.

Related Products

- 5SGY3545L0003: Basic model in the same series, ideal for standard automation scenarios with excellent cost-performance

- 5SGY3545L0020: Enhanced module with stronger communication processing capabilities, perfect for complex network environments

- 5SHY3545L0009: High-performance thyristor module designed for high-power control applications

- PM861AK01: ABB AC800M series processor, compatible with the 5SGY3545L0008 to enhance system computing power

- PPD113B01: Signal conditioning module that expands system signal processing capabilities

- PFEA111: Interface module providing additional I/O expansion for more point requirements

- CI871K01: Communication interface module improving network connection stability for complex industrial networks

Installation & Maintenance Guidelines

Pre-Installation Preparation

Don’t rush into installation—spend a few minutes verifying environmental parameters first: temperature, humidity, and vibration must meet the module’s requirements, and power supply voltage should match the rated value. Prepare necessary installation tools and accessories in advance to avoid delays. For DIN rail mounting, confirm rail specifications and installation space—you don’t want to find out the module doesn’t fit halfway through!

Installation Tips

This module uses standard DIN rail mounting—ensure it’s securely fixed, as industrial vibration can easily loosen connections and cause malfunctions. Be extra careful during wiring: never reverse power polarity, strictly follow signal cable shielding requirements, and stick to the wiring diagram step by step. For multi-module systems, leave sufficient spacing between modules to ensure proper heat dissipation—only with unobstructed cooling can equipment operate stably long-term.

Maintenance Recommendations

Regularly check the module’s status indicators to detect abnormalities early. Keep the module surface clean—excessive dust accumulation impairs heat dissipation and shortens service life. During system shutdowns for maintenance, perform performance tests to check for changes in input/output characteristics. If performance degrades after long-term operation, don’t attempt to disassemble the module yourself—contact professional technicians for diagnosis and maintenance.

Product Warranty & Support

ABB takes quality seriously for the 5SGY3545L0008—every unit undergoes multiple rigorous tests before leaving the factory, from components to overall performance, ensuring compliance with ABB’s high-quality standards.

During the warranty period, ABB provides free repair or replacement for non-human-induced failures, giving users peace of mind. What’s more, ABB’s professional technical support team offers full-cycle services, from system commissioning and fault diagnosis to daily maintenance. A mature logistics system ensures timely delivery of spare parts, minimizing downtime losses for users. Ultimately, ABB aims to build long-term, stable partnerships with customers, creating mutual value through reliable products and attentive service.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com