Description

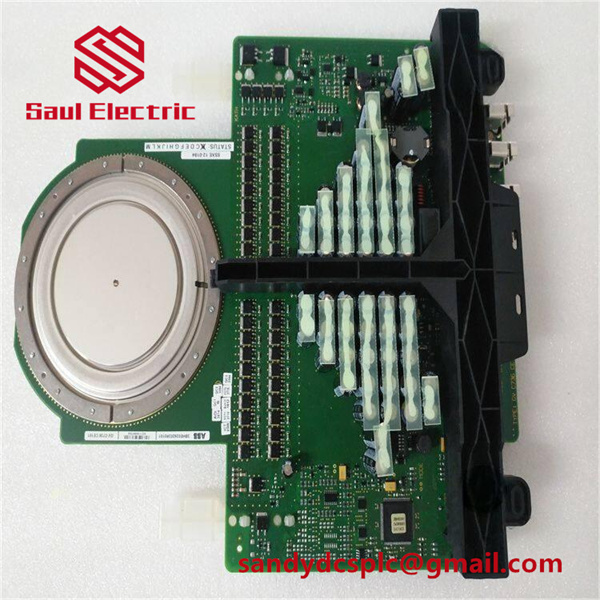

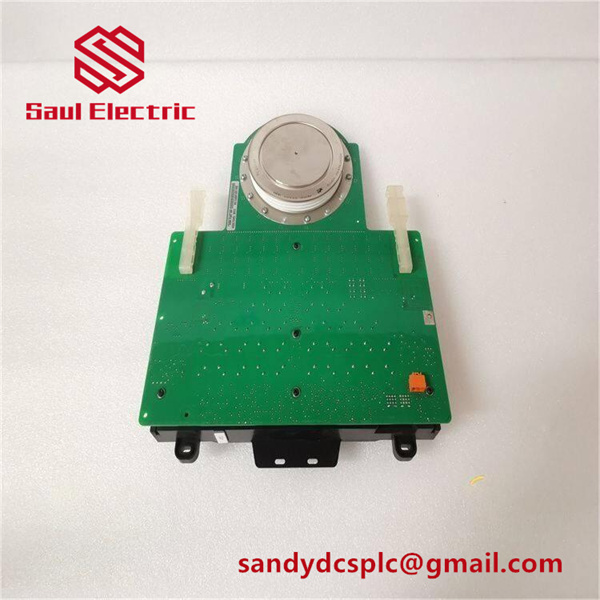

ABB 5SGX1060H0003 PLC Module: The Hardcore Core of Industrial Automation

The 5SGX1060H0003 Programmable Logic Controller (PLC) module, part of ABB’s AC500 series, stands as the “neural hub” of industrial automation control systems. Having worked with numerous industrial control modules, I’ve found this one’s computing efficiency truly impressive—equipped with advanced processors and high-speed memory technology, it handles complex control algorithms and logic instructions with ease. Its high-speed, precise control performance perfectly meets the stringent demands for real-time responsiveness and reliability in modern industrial automation. Pair that with flexible communication interfaces and robust processing power, and it becomes an almost irreplaceable choice for complex control systems.

As a key member of ABB’s automation product lineup, this module features a modular design that seamlessly accommodates various I/O modules and functional expansion cards, allowing for flexible configuration tailored to practical application needs. Practicality and reliability were clearly prioritized in its design: high-quality materials and advanced manufacturing processes ensure stable operation even in harsh industrial environments. Within industrial automation systems, it excels at both local control tasks and data exchange with upper-level management systems via multiple communication protocols—truly a versatile workhorse.

Core Technical Specifications

| Parameter Name | Parameter Details |

|---|---|

| Product Model | 5SGX1060H0003 |

| Manufacturer | ABB |

| Product Type | Programmable Logic Controller (PLC) Module |

| Operating Voltage | 24VDC or 220VAC |

| Processing Speed | 150/60Hz |

| Program Capacity | 50000 |

| Data Capacity | 100 |

| Communication Protocols | Ethernet/IP, Modbus TCP/IP, PROFIBUS PA, etc. |

| Ambient Temperature | -40°C to +85°C (some data suggests it can withstand up to +100°C) |

| Dimensions | 45mm × 45mm (alternative data lists 200 × 180 × 50mm) |

| Weight | Approximately 1kg—solid and substantial in hand |

| Installation Method | Modular Installation |

Its most striking advantages lie in processing performance and communication flexibility. Equipped with a high-speed FPGA and dual-core ARM Cortex-A9 processor architecture—essentially “dual engines” for the module—it delivers exceptional data processing and logic operation speeds, tackling complex control algorithms and real-time tasks effortlessly. Interestingly enough, industrial settings have no tolerance for lag, and this module’s response speed hits the sweet spot. It’s particularly well-suited for industrial applications requiring rapid responsiveness and precise control.

Communication integration is another major plus. Supporting multiple industrial communication protocols allows it to seamlessly integrate into existing industrial network architectures—after all, factories house a hodgepodge of equipment. Compatibility with mainstream protocols like Ethernet/IP, Modbus TCP/IP, and PROFIBUS PA simplifies system integration significantly. Its flexible I/O expansion capabilities also deserve a mention, adapting to both digital and analog input/output modules for customized configurations based on specific application needs.

Reliability and durability were clearly top priorities in the design. High-quality electronic components and advanced manufacturing processes enable stable operation across a wide temperature range (-40°C to +85°C and beyond), handling harsh industrial environments with ease. The low-power design is a thoughtful touch too—not only reducing energy consumption but also enhancing thermal stability and extending service life. Paired with development tools like ABB Control Builder M, programming and debugging become a breeze, drastically cutting down on system development and maintenance time.

This high-performance automation control module has already gained a solid foothold across multiple industrial sectors. In industrial automation, it’s a common sight in Manufacturing Execution Systems (MES), process control workflows, and power distribution systems, maximizing production equipment control precision and naturally boosting efficiency and product quality. Can it adapt to almost all high-end manufacturing scenarios you can think of? Absolutely.

In mechanical equipment control, it’s widely used in CNC machine tools, mold engraving equipment, and laser cutting systems. Its high-precision control ensures the accuracy and stability of mechanical operations, while its rapid response meets the demands of high-speed processing. For building automation, it manages HVAC systems, lighting control, and other building equipment, enabling efficient energy use and intelligent device management.

It even plays a crucial role in robot control systems, medical imaging and diagnostic equipment, and aerospace and defense systems. These critical applications have notoriously strict requirements for reliability and real-time performance—and this module delivers. Whether used as a standalone controller or part of a large distributed control system, it provides stable, reliable control solutions tailored to the diverse needs of different industries.

There are plenty of excellent “partners” to pair it with. The 5SHY3545LXXX ABB IGCT thyristor mainboard, part of the same automation product family, works in tandem with it to double efficiency in high-power power control systems. The 5SHY4045LXXX ABB thyristor module is another perfect collaborator for power control applications.

The PFEA111 tension meter/sensor pairs seamlessly to achieve high-precision tension measurement and control. The PFEA113 sensor module serves as its input device, handling on-site signal acquisition. The PFTL101A sensor product offers great compatibility, expanding the system’s measurement capabilities. The PFTL201CE advanced sensor module acts as a feedback device for the control system. The GVC7XXAE/BEXX controller module shares the same ABB control product platform, making it ideal for building distributed control systems. The 5SXEXX-XXXX series modules, built on the same design philosophy and technical foundation, are essentially its “technical siblings.”

Installation requires careful attention to detail. First, confirm the working environment meets the module’s technical requirements—especially power supply voltage and ambient temperature. The installation location must have sufficient space for heat dissipation and maintenance, as these directly impact service life. For use in special environments like hazardous areas, current output configuration is critical. If deployed in Zone 1/Div.1, the active/passive mode of the current output must be specified at the time of order and cannot be changed later.

While the module is designed for reliability, regular preventive maintenance is still essential. During maintenance, check the module’s fixation and connector tightness to ensure reliable electrical connections. For modules with PROFIBUS PA interfaces, verify or configure the bus address before startup—ensuring it falls within the valid range (0-125) and is unique on the network. Daily maintenance should also include monitoring operational status indicators and regularly cleaning heat dissipation surfaces to maintain effective cooling. When replacement or upgrading is needed, strictly follow ABB’s technical specifications to avoid unnecessary damage. In practice, many malfunctions stem from overlooked installation details or careless maintenance—small issues that are easily avoidable with a bit of attention.

ABB backs this module with robust quality assurance. All factory-fresh products undergo rigorous testing and inspection, fully complying with ABB’s high-quality standards. For quality issues arising from normal use during the warranty period, free replacement is offered—giving customers peace of mind. Even beyond the warranty, ABB and authorized suppliers continue to provide technical support, charging only for component costs.

Professional technical support is readily available, covering system debugging, fault diagnosis, maintenance guidance, and more. Suppliers commit to responding to customer inquiries within 1 hour and operate a 24/7 service hotline for immediate assistance. Even if the equipment is discontinued, alternative models and replacement process support are provided to ensure uninterrupted, stable operation of customer systems. Ultimately, ABB’s goal is to maintain the module’s optimal performance throughout its entire lifecycle—offering customers complete reassurance.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com