Description

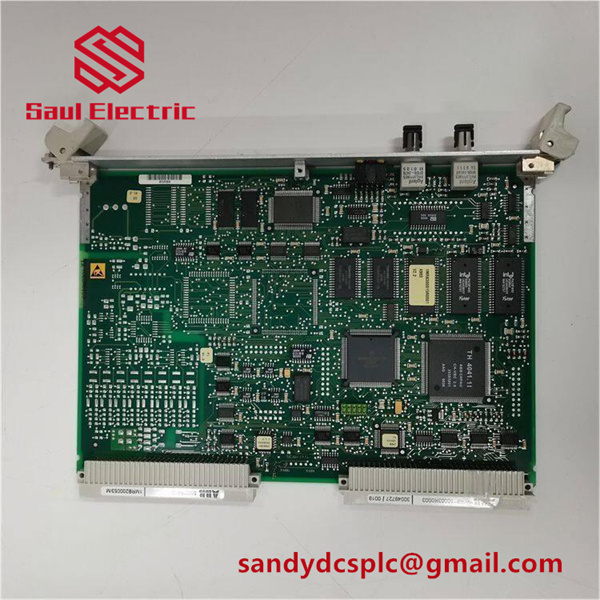

ABB 500MBA02 1MRB200053/M Product Description

Product Overview

ABB 500MBA02 1MRB200053/M is a high-performance industrial motor from ABB Group, a true standout in the company’s motor lineup. It efficiently converts electrical energy to mechanical energy through electromagnetic induction, featuring a modular structure and heavy-duty design tailored specifically for the harsh conditions of industrial environments. Acting as the “power core” of industrial machinery, it boasts a wide voltage range of 220-690V and compatibility with 50/60Hz dual-frequency power grids. With an IP55 protection class and Class F insulation (assessed by Class B temperature rise), it delivers stable long-term operation even in tough working conditions—let’s be honest, voltage fluctuations are common in industrial settings, and this dual-frequency compatible design really saves the day.

The motor’s iron core uses cold-rolled silicon steel sheets treated with vacuum impregnated insulation varnish, while its windings adopt enameled wires resistant to 200°C high temperatures. This design effectively controls temperature rise and boosts efficiency. In industrial automation systems, it functions like a central power hub, working in seamless coordination with frequency converters, circuit breakers, and other control components to provide reliable power for various mechanical equipment. Its optimized electromagnetic design and mechanical structure excel in efficiency, reliability, and service life, helping users cut down on total operating costs in tangible ways.

As a representative product in ABB’s motor series, this model embodies the company’s years of technical expertise in motor manufacturing. It meets the equipment needs of multiple industrial sectors—mining, metallurgy, power generation, food processing, to name a few. Manufactured in compliance with international standards, it’s compatible with the installation dimensions of domestic Y-series motors, making upgrades to existing equipment a breeze without major overhauls.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 500MBA02 1MRB200053/M |

| Manufacturer | ABB Group |

| Product Type | Three-phase Asynchronous Motor |

| Protection Class | IP55 |

| Insulation Class | Class F (assessed by Class B temperature rise) |

| Rated Voltage Range | 220-690V |

| Power Frequency | 50/60Hz dual-frequency compatible |

| Bearing Type | Imported NSK or SKF bearings (lifetime maintenance-free) |

| Cooling Method | Self-ventilated (IC411) |

| Installation Method | Multiple options including IM B3/B35/B5 |

| Operating Temperature Range | -25°C to +50°C |

| Protection Features | Totally enclosed fan-cooled structure with anti-corrosion design |

Key Features and Advantages

Boasting advanced electromagnetic optimization, this motor meets IE3 efficiency standards, reducing energy consumption significantly—over the long run, the savings on electricity bills are quite substantial. Its 220-690V wide voltage design proves highly practical; even in unstable grid environments, such as factories with noticeable voltage fluctuations during peak hours, it operates steadily. The modular design offers great flexibility, adapting to different needs for installation configurations and accessory expansions.

It runs with low vibration and noise, quieter than the industry average, thanks to the refined tuning of its electromagnetic system and cooling structure. Equipped with high-quality imported bearings and a dedicated lubrication system, it supports maintenance-free operation for over 2000 hours, drastically cutting downtime and maintenance costs. The motor housing is made of high-strength anti-corrosion cast iron with a special surface treatment, resistant to chemical corrosion and humidity in industrial environments.

A built-in temperature monitoring system tracks winding temperature rise in real time. Combined with Class F insulation materials, it ensures safe operation even in high-temperature environments while extending service life. For enhanced protection, optional winding protection accessories like PTC thermistors and anti-condensation heating belts are available—adding an extra layer of security for the motor.

Application Fields

Widely used in industrial manufacturing, it’s ideal for driving key process equipment such as pumps, fans, compressors, and conveying systems. Processing machinery, assembly equipment, and material handling systems on production lines rely on its continuous power to maintain uninterrupted production processes. For 24/7 operation scenarios, its energy-efficient performance translates to tangible reductions in energy costs.

In the energy sector, it’s commonly used to drive power plant auxiliary equipment, water treatment systems, and oil and gas transmission devices. These environments often involve high temperatures and humidity, but the motor’s robust protection capabilities handle them with ease. It’s also a staple in the construction and infrastructure sectors, powering elevators, ventilation systems, air conditioning units, and water pumps—especially in commercial buildings with strict noise requirements, where its low-noise advantage stands out.

In heavy industries like metallurgy, mining, and heavy machinery, it delivers exceptional performance. It can withstand harsh conditions such as high-load impacts and frequent start-stops. Its solid mechanical structure and efficient heat dissipation ensure long-term reliability in heavy-duty applications. In process industries like papermaking and chemicals, it can tackle corrosive environments and special process requirements with customized protective measures.

Related Products

- M2QA Series: Standard three-phase asynchronous motors in the same series, with a power range of 0.18-315kW, suitable for basic selection needs

- QABP Series: Frequency control-specific motors, designed for variable frequency drive applications, enabling precise speed regulation

- M2JA Series: Explosion-proof three-phase asynchronous motors, suitable for flammable and explosive hazardous environments

- QAEJ Series: Electromagnetic brake motors with integrated braking function, ideal for applications requiring rapid stopping and positioning

- M2SV Series: Flue-specific motors, specially optimized for ventilation and smoke exhaust systems

- Tmax XT Circuit Breakers: Matching protection equipment, providing overload and short-circuit protection

- ACS510 Frequency Converters: Matching frequency control solutions, supporting soft start/stop and energy-saving operation of motors

Installation and Maintenance

Before installing the motor, it’s a good idea to check the nameplate data to confirm it meets application requirements. Inspect the mechanical assembly for integrity, verify correct wiring, and ensure the insulation resistance measures no less than 0.5MΩ—electrical safety is non-negotiable. During installation, the motor must be mounted vertically on a flat foundation with an inclination not exceeding 5°, and cooling holes should face upward for optimal heat dissipation and ventilation. Different installation methods (B3, B35, B5) must follow corresponding specifications—no arbitrary modifications allowed.

Regular maintenance is crucial for long-term stable operation. Keep an eye on the motor temperature to ensure it stays within the normal range, maintain a clean surface to prevent dust buildup, and adhere to the lubrication schedule: first lubrication after 500 hours of initial operation, followed by regular replacements every 2000 hours. During daily monitoring, listen for abnormal operating noises, check for stable current and voltage, and inspect cable connections for tightness. In harsh operating environments, shorten the inspection cycle and focus on bearing conditions and insulation performance.

Product Assurance

ABB provides comprehensive quality assurance and professional technical support for this motor. Manufactured in full compliance with the ISO9001 quality management system and international/domestic standards such as IEC 60034 and GB 755, every step—from raw material procurement to finished product delivery—undergoes strict quality control. Leveraging ABB’s global service network, users receive timely technical consultation, installation guidance, and fault diagnosis support, ensuring the motor’s performance is fully utilized.

The product comes with ABB’s standard warranty. Under normal usage conditions, if failures occur due to material or manufacturing defects, ABB offers free repair or replacement. For special application requirements, ABB can also provide customized technical solutions and extended warranty options. The comprehensive after-sales service system gives users peace of mind during operation, maximizing the return on equipment investment.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com