Description

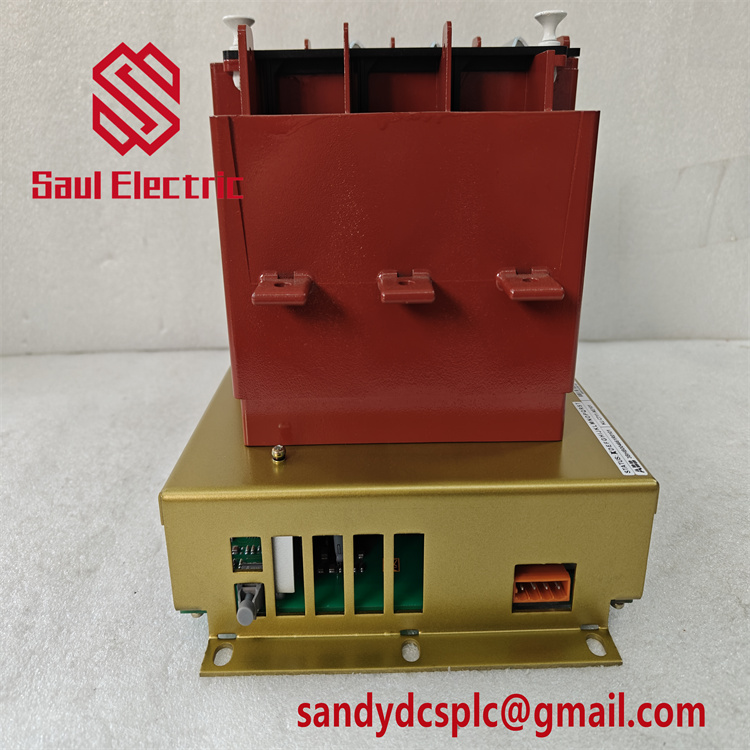

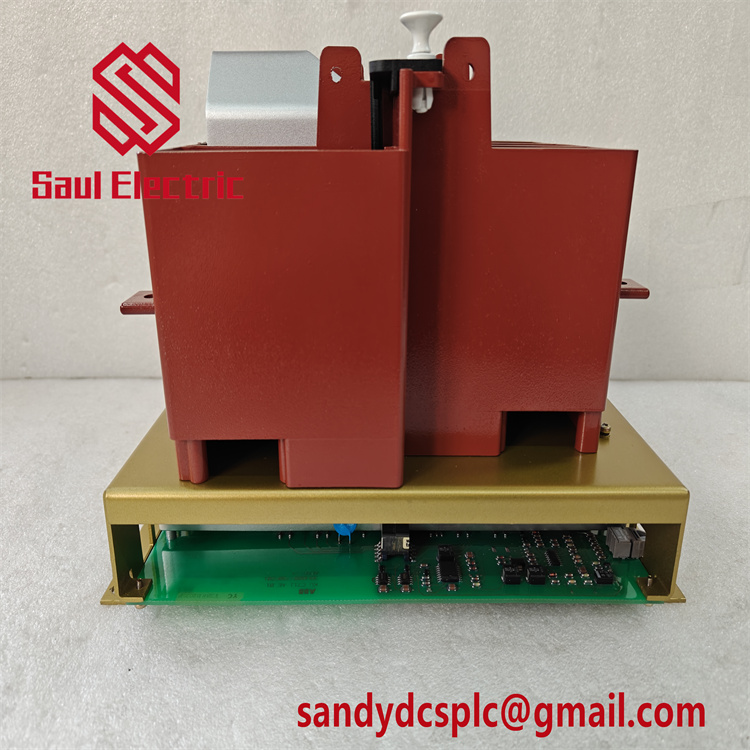

ABB KUC720AE is a High-Performance Industrial Control Module designed for advanced automation systems, combining real-time control, data processing, and communication capabilities. Engineered for industrial environments, it serves as a core component in applications requiring precision and reliability across manufacturing, power generation, and process industries. Below is a detailed technical breakdown:

Product Overview

The ABB KUC720AE is a compact, DIN rail-mountable module that integrates logic control, motion control, and multi-protocol communication into a single platform. It supports high-frequency signal processing (up to 50 kHz) and advanced control algorithms, making it ideal for demanding applications like robotic welding, chemical reaction monitoring, and power grid stabilization .

As part of ABB’s Industrial Automation portfolio, the KUC720AE interfaces seamlessly with PLCs, HMIs, and third-party systems. Its modular design allows scalability, with expandable I/O modules for analog/digital signals and fieldbus connectivity (EtherCAT, PROFIBUS, Modbus) . The module’s rugged IP20-rated housing (UL 94 V-0 plastic) ensures operation in harsh conditions, including temperatures ranging from -10°C to +55°C and exposure to dust and vibrations .

Key functionalities include:

- Real-Time Logic Control: Supports ladder diagram (LAD) and structured text (ST) programming for complex automation sequences.

- High-Frequency Motion Control: Precise speed and torque regulation for CNC machines and robotic arms.

- Data-Driven Decision Making: Onboard data analytics for predictive maintenance and process optimization.

- Redundant Communication: Dual-channel Ethernet ports for fault-tolerant connectivity in mission-critical systems.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | ABB KUC720AE |

| Manufacturer | ABB |

| Product Type | Industrial Control Module (Logic, Motion, and Communication) |

| Input Voltage | 24 V DC ±10% |

| Output Voltage | 5 V DC (for internal circuits), 24 V DC (for external peripherals) |

| Processor | 32-bit ARM Cortex-A9 @ 800 MHz |

| Memory | 512 MB DDR3 RAM, 4 GB eMMC flash |

| Communication Protocols | Ethernet, EtherCAT, PROFIBUS DP, Modbus TCP/RTU |

| I/O Expansion | Up to 128 digital I/O or 32 analog I/O via expansion modules |

| Operating Temperature | -10°C to +55°C (non-condensing) |

| Weight | 0.8 kg |

| Dimensions | 125 mm × 100 mm × 75 mm |

| Certifications | CE, UL, CSA, EAC |

| MTBF | 100,000 hours |

Key Features and Advantages

Multi-Domain Control: Combines logic, motion, and communication control in a single module, reducing system complexity and cabling costs. The KUC720AE can simultaneously manage robotic arm trajectories, monitor chemical reactor parameters, and communicate with cloud-based analytics platforms .

High-Frequency Precision: With a 50 kHz signal processing capability, it excels in high-speed applications like high-frequency induction heating and precision soldering, ensuring ±0.1% temperature stability . Its dual PID control mode and fuzzy logic algorithms optimize dynamic response in varying loads.

Rugged Reliability: The IP20-rated enclosure and conformal coating protect against dust, moisture, and electromagnetic interference. Built-in self-diagnostic tools (e.g., voltage monitoring, thermal overload protection) minimize downtime and maintenance efforts .

Scalable Architecture: Modular design allows easy integration of additional I/O modules (e.g., analog input/output, temperature control) for adapting to evolving production requirements. This flexibility is critical in industries like automotive manufacturing, where production lines often undergo reconfiguration .

User-Friendly Interface: Equipped with an intuitive LCD display and push-button controls, the KUC720AE enables on-device parameter adjustment and real-time status monitoring. Its web-based configuration tool simplifies programming and remote diagnostics .

Applications

- Automotive Manufacturing: Controls robotic welding and assembly lines, ensuring precision in car body production. Integrates with vision systems for quality inspection, reducing defects by up to 90% .

- Chemical Processing: Monitors temperature, pressure, and flow in reactors, enabling closed-loop control for optimal reaction efficiency. Supports predictive maintenance by analyzing sensor data to detect anomalies .

- Power Generation: Manages substation automation systems, coordinating voltage regulation and grid synchronization. Its high-frequency control capabilities are vital for stabilizing renewable energy grids .

- Electronics Production: Drives high-frequency soldering equipment in PCB manufacturing, achieving solder joint precision within ±0.05 mm. Ensures consistent quality in mass production .

- Heavy Machinery: Optimizes motion control in CNC machine tools, improving machining accuracy to ±0.01 mm. Reduces energy consumption by 15% through intelligent torque regulation .

Related Products

- ABB KUC720AE01: High-frequency variant with 50 kHz output for specialized applications like induction heating and precision welding .

- ABB KUC720AE101: Enhanced version with extended memory (1 GB RAM) and dual Ethernet ports for redundant communication in critical systems .

- ABB AC800F DCS: Distributed control system compatible with the KUC720AE for large-scale process automation .

- ABB PSR-SCP-24VDC: Backup power supply ensuring uninterrupted operation of the KUC720AE in mission-critical scenarios .

- ABB CI860 Communication Module: Expands connectivity options for multi-vendor systems, supporting PROFINET RT and EtherNet/IP .

Installation & Maintenance

Installation Preparation:

- Mount vertically on a 35 mm DIN rail in control cabinets, leaving 20 mm clearance for ventilation.

- Connect 24 V DC power using 1.5 mm² stranded wires with 0.5 N·m torque. Verify grounding compliance with IEC 60364 standards.

- Configure communication protocols via ABB’s Automation Builder software, ensuring compatibility with existing network infrastructure .

Maintenance Recommendations:

- Clean dust from the module’s vents quarterly using compressed air (max 2 bar). Avoid liquid contact with internal components.

- Update firmware annually to access new features and security patches. ABB provides remote support for software upgrades.

- Inspect I/O connections biannually for corrosion or loose terminals. Replace worn-out modules to maintain signal integrity .

Product Warranty & Support

The ABB KUC720AE comes with a 1-year warranty covering defects in materials and workmanship. ABB’s global support network offers 24/7 technical assistance, including remote diagnostics and replacement parts. Local distributors in Xiamen, China (e.g., Xiamen Amikon Technology Co., Ltd.) maintain spot inventory with 3-day delivery after payment .

Abb INICT01 Infi 90 Bailey Transfer Module

INIET800 Monitor/Control by – ABB – BAILEY CONTROLS

ABB Bailey INIIT03 Net Transfer Module

IMSET01 ABB PLC module New IMSET01

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com