Description

Many products are not yet available—feel free to contact us for more options.

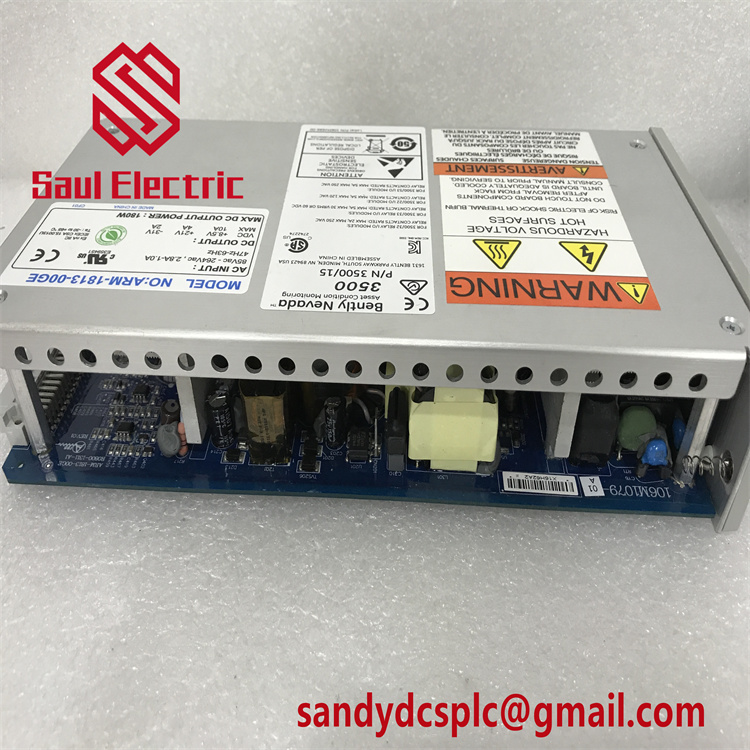

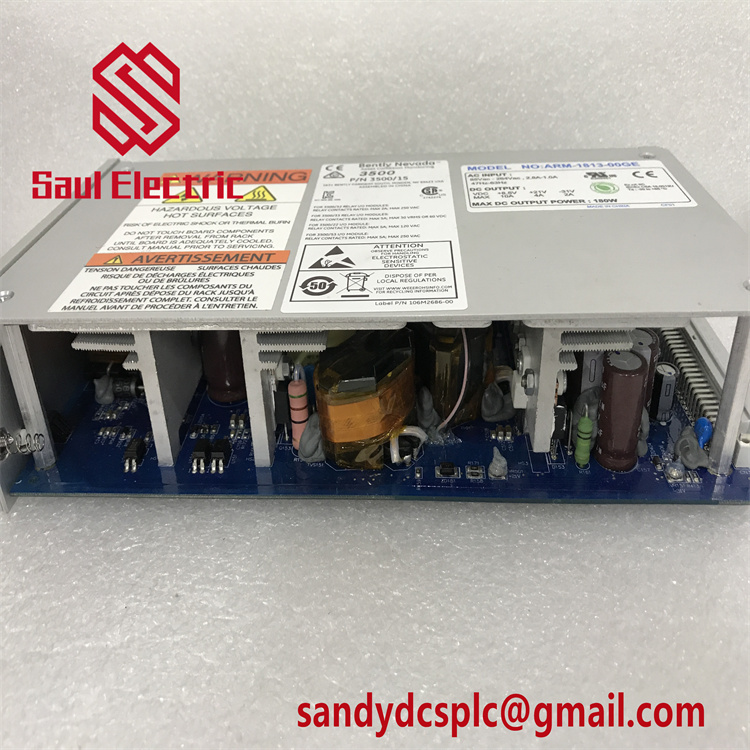

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The BENTLY 3500/72M 135489-01 is a robust machine protection and monitoring module designed by BENTLY Nevada for critical machinery applications. As part of the BENTLY 3500 series, this module provides essential functionality for monitoring key performance parameters such as vibration, speed, and displacement in high-value rotating equipment, including turbines, compressors, and motors. With its advanced diagnostic capabilities, the BENTLY 3500/72M 135489-01 offers real-time data collection and fault detection, enabling operators to identify potential issues before they result in catastrophic failures or unplanned downtime.

The BENTLY 3500/72M 135489-01 is engineered for reliability, ensuring consistent performance even in demanding industrial environments. It is a critical component for implementing predictive maintenance strategies, reducing maintenance costs, and improving machinery uptime. The module supports both Modbus TCP/IP and RS-485 communication protocols, allowing easy integration with existing automation systems for centralized monitoring and remote diagnostics.

Designed to operate in extreme conditions, the BENTLY 3500/72M 135489-01 ensures machinery health is consistently monitored, providing early warnings to reduce the risk of unplanned shutdowns and avoid expensive repairs.

Technical Specifications

| Parameter Name | Value |

|---|---|

| Product Model | BENTLY 3500/72M 135489-01 |

| Manufacturer | BENTLY Nevada |

| Product Type | Machine Protection and Monitoring Module |

| Power Input | 24 V DC |

| Input Signal Type | Vibration, Speed, Displacement |

| Communication Protocol | Modbus TCP/IP, RS-485 |

| Operating Temperature Range | -40°C to 85°C |

| Storage Temperature Range | -40°C to 85°C |

| Dimensions | 4.5 x 10 x 10 cm |

| Weight | 1.3 kg |

| Certification | CE, UL |

| Max Input Current | 150 mA |

| Measurement Accuracy | ±1% FS |

Key Features and Benefits

Complete Monitoring Solution: The BENTLY 3500/72M 135489-01 provides comprehensive monitoring of vital machinery parameters including vibration, speed, and displacement. This allows operators to monitor equipment in real-time and detect potential issues before they lead to equipment failure, ensuring smoother operations and extended equipment life.

Advanced Protection: The module is designed to protect critical equipment by offering early fault detection for issues such as excessive vibration or abnormal speed variations. By identifying these issues early, operators can take preventative actions before costly damage occurs.

Durable in Harsh Environments: Built for use in challenging industrial conditions, the BENTLY 3500/72M 135489-01 operates effectively in environments with high temperatures and vibrations. It is ideal for industries like power generation, petrochemical, and heavy manufacturing, where equipment reliability is critical for maintaining operational continuity.

Seamless System Integration: The BENTLY 3500/72M 135489-01 supports both Modbus TCP/IP and RS-485 communication protocols, allowing easy integration into existing automation systems. This enables centralized monitoring and real-time diagnostics, helping operators make informed decisions based on accurate data.

Predictive Maintenance: By continuously monitoring equipment performance, the BENTLY 3500/72M 135489-01 aids in implementing a predictive maintenance strategy. Early detection of irregularities allows for timely repairs, reducing unplanned downtime and minimizing overall maintenance costs.

Application Areas

The BENTLY 3500/72M 135489-01 is commonly used in industries where reliable, continuous operation of machinery is critical. It is particularly beneficial in sectors such as power generation, petrochemical, oil and gas, and manufacturing.

In power generation, the BENTLY 3500/72M 135489-01 is used to monitor the health of turbines, generators, and other essential machinery, ensuring that issues like excessive vibration or speed variations are detected early. This helps prevent unplanned shutdowns and costly repairs, thereby optimizing the plant’s efficiency and performance.

In the petrochemical and oil and gas industries, this module is used for real-time monitoring of pumps, compressors, and motors. The BENTLY 3500/72M 135489-01 helps improve the reliability and safety of critical equipment, enhancing productivity by minimizing the risk of equipment failure.

Related Products

ABB IGCT 5SHY4045L0006 3BHB030310R0001 Module

3500/40M 176449-01+125680-01 Bently Nevada

176449-01 3500/40M Bently Nevada Proximitor Monitor

3500/40-01-00 | Bently Nevada Proximitor Monitor

Bently Nevada 3500/40-01-00 125680-01 Proximitor I/O

Bently Nevada 3500/40 3500/40M 176449-01 140734

Installation and Maintenance

Installation Preparation: Before installing the BENTLY 3500/72M 135489-01, ensure that the system is powered off and the installation location is free from excessive vibrations or environmental hazards. Follow the product manual for specific instructions on wiring and input signal connections to ensure proper functionality.

Maintenance Recommendations: Regular maintenance and calibration are required to ensure the BENTLY 3500/72M 135489-01 operates correctly. Periodically check the wiring connections and communication system for any signs of wear or damage. Cleaning the module to prevent dust buildup will help maintain optimal performance.

Product Warranty

BENTLY 3500/72M 135489-01 comes with a one-year warranty, offering robust technical support and after-sales service. Should any issues arise, our dedicated support team is available to provide troubleshooting and repair assistance, ensuring continued reliability and performance of your equipment.

HS:7326909000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com