Description

Product Overview

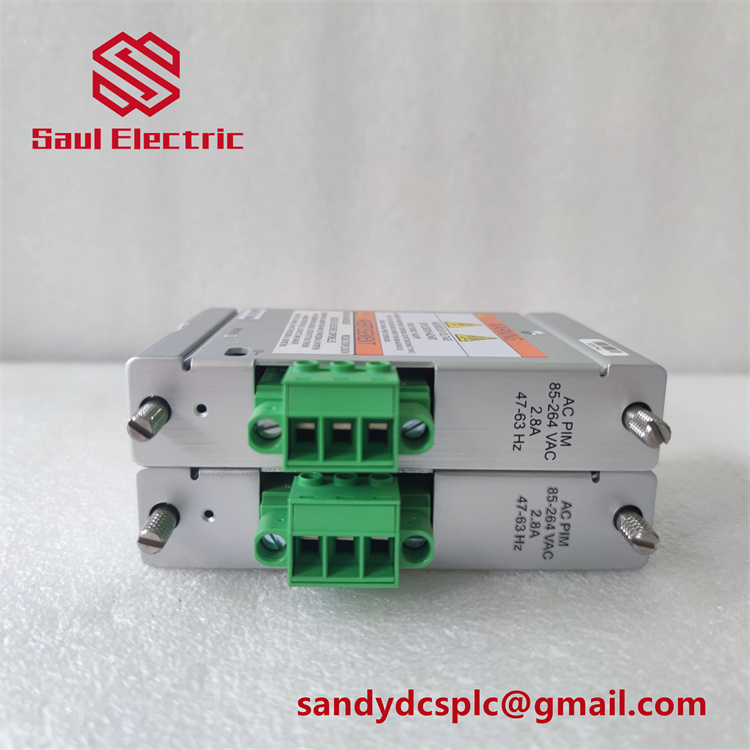

BENTLY 3500/70 140471-01 is a vibration monitoring module developed by BENTLY Nevada, designed for use in industrial automation systems to monitor and diagnose the vibration conditions of critical machinery. As part of the BENTLY 3500 series, this module plays a vital role in predictive maintenance and real-time monitoring, enabling users to detect potential faults early and improve the efficiency and reliability of machinery.

The BENTLY 3500/70 140471-01 module provides precise vibration measurements through advanced signal processing technology. It supports a range of input signals including acceleration, velocity, and displacement, ensuring compatibility with different types of equipment. The module is designed for use in a variety of industrial environments, including power generation plants, petrochemical facilities, and manufacturing plants, where machinery health monitoring is critical.

With its reliable performance and integration capabilities, the BENTLY 3500/70 140471-01 is an essential component for industries seeking to implement predictive maintenance strategies, reduce unplanned downtime, and extend the life cycle of their equipment. By providing real-time data on vibration levels, the module helps prevent costly repairs and downtime due to unexpected equipment failures.

Technical Specifications

| Parameter Name | Value |

|---|---|

| Product Model | BENTLY 3500/70 140471-01 |

| Manufacturer | BENTLY Nevada |

| Product Type | Vibration Monitoring Module |

| Power Input | 24 V DC |

| Input Signal Type | Acceleration, Velocity, Displacement |

| Communication Protocol | Modbus TCP/IP, RS-485 |

| Operating Temperature Range | -40°C to 85°C |

| Storage Temperature Range | -40°C to 85°C |

| Dimensions | 4.5 x 10 x 10 cm |

| Weight | 1.2 kg |

| Certification | CE, UL |

| Max Input Current | 150 mA |

| Vibration Measurement Accuracy | ±1% FS |

Key Features and Benefits

Precision Vibration Monitoring: The BENTLY 3500/70 140471-01 offers high-precision vibration measurements, capturing even the smallest vibration changes. This allows users to monitor the condition of critical equipment and detect early signs of mechanical issues before they result in significant failures.

Versatile Signal Input: The module supports a wide range of vibration input signals, including acceleration, velocity, and displacement, making it adaptable to various machinery and monitoring requirements.

Reliability in Harsh Environments: Designed for industrial use, the BENTLY 3500/70 140471-01 is highly reliable and capable of performing in challenging environments. It is built to withstand temperature extremes and harsh industrial conditions, ensuring long-term performance and reduced maintenance needs.

Advanced Communication Integration: The module supports Modbus TCP/IP and RS-485 communication protocols, allowing seamless integration with other automation systems. This ensures that real-time monitoring data can be transmitted to central systems for further analysis and reporting.

Predictive Maintenance Capability: The BENTLY 3500/70 140471-01 enables predictive maintenance by continuously monitoring vibration levels and providing early warning signs of potential failures. This helps users reduce downtime, optimize maintenance schedules, and lower operational costs.

Application Areas

The BENTLY 3500/70 140471-01 is ideal for applications in industries that rely on the smooth operation of large, complex machinery. Its primary applications include power generation, petrochemical, oil and gas, and manufacturing industries.

In power generation plants, BENTLY 3500/70 140471-01 is used to monitor the vibration of turbines, pumps, and other critical equipment, helping operators ensure optimal performance and reduce the likelihood of unexpected failures.

In the petrochemical and oil and gas industries, the module is used to monitor compressors, pumps, and motors, providing real-time vibration data to support predictive maintenance strategies and prevent costly unplanned shutdowns.

Related Products

3500/40M 176449-01+125680-01 Bently Nevada

176449-01 3500/40M Bently Nevada Proximitor Monitor

3500/40-01-00 | Bently Nevada Proximitor Monitor

Bently Nevada 3500/40-01-00 125680-01 Proximitor I/O

Bently Nevada 3500/40 3500/40M 176449-01 140734

Installation and Maintenance

Installation Preparation: Before installing the BENTLY 3500/70 140471-01, ensure the system is powered down and the installation area is prepared according to the product manual. Confirm that the module is installed in the correct location, and properly connect it to the vibration input terminals to ensure accurate measurements.

Maintenance Recommendations: Regular functionality tests and calibration should be performed on the BENTLY 3500/70 140471-01 to ensure it operates correctly. Inspect the module for proper connections and confirm that environmental factors do not interfere with its performance. Additionally, the module should be cleaned periodically to prevent dust or debris buildup, ensuring optimal performance.

Product Warranty

BENTLY 3500/70 140471-01 comes with a one-year warranty, providing users with comprehensive technical support and after-sales service. Customers are entitled to consult our support team for product troubleshooting and receive prompt assistance with repairs if needed. We are committed to maintaining the highest standards of quality and performance for all our products.

HS:7326909000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com