Description

Many products are not yet available—feel free to contact us for more options.

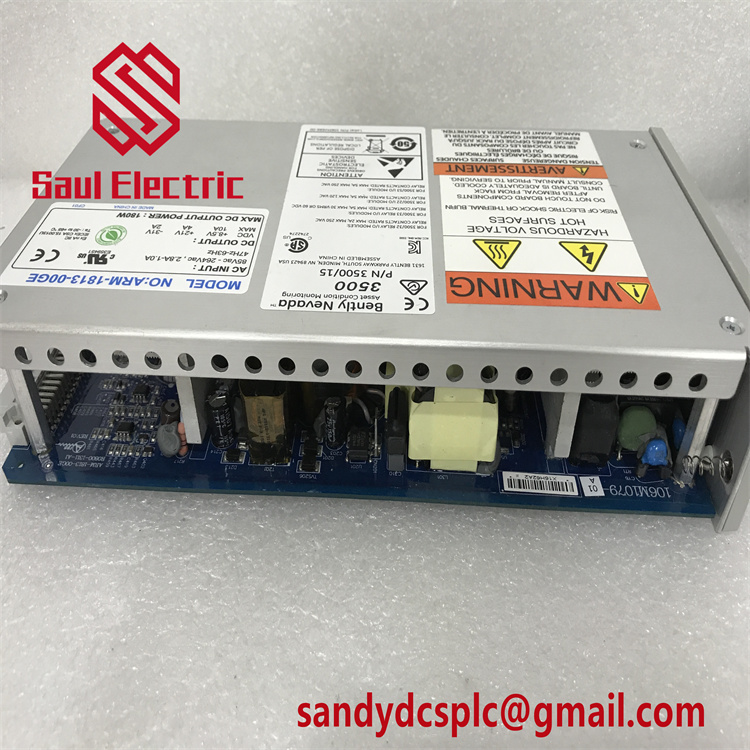

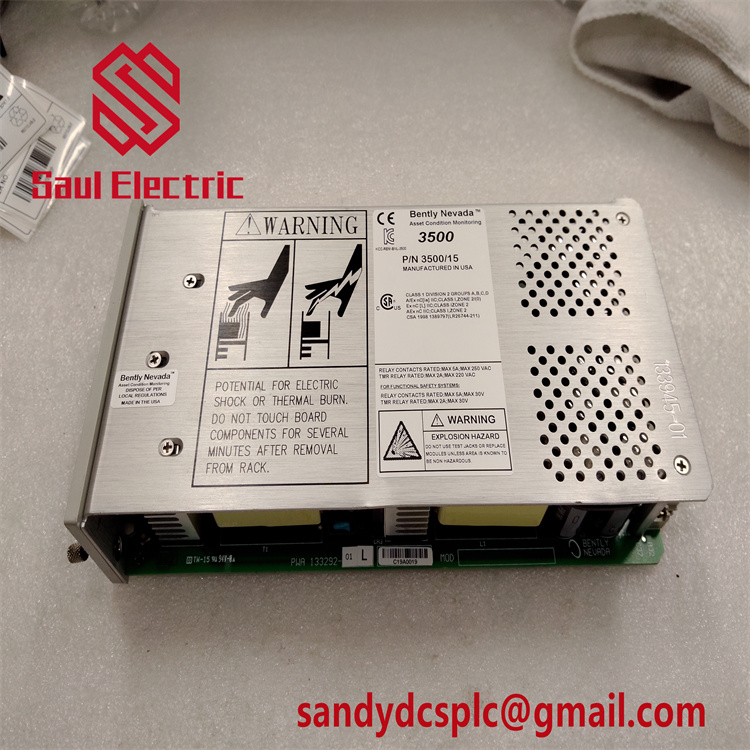

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

BENTLY 3500/42-04-00 Proximitor Seismic Monitor

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 3500/42-04-00 |

| Manufacturer | BENTLY NEVADA |

| Product Type | Proximitor Seismic Monitor (4-channel) |

| Input Voltage | 9–36 VDC |

| Channels | 4 (configurable for vibration/displacement) |

| Accuracy | ±0.33% of full scale (typical) |

| Frequency Response | 0.01 Hz to 1000 Hz |

| Communication Protocol | Modbus RTU, Ethernet/IP, RS-485, DeviceNet, CANopen |

| Physical Dimensions | 24.18 cm (L) x 2.44 cm (W) x 24.13 cm (D) |

| Weight | 0.91 kg (with I/O module) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 95% non-condensing |

| Mounting | 3500 Series rack-mounted |

| Sensor Compatibility | Proximity probes, seismic accelerometers |

| Certifications | ATEX, CE, NEPSI (China hazardous area) |

| Data Acquisition Rate | Up to 100 samples/second |

| I/O Module Part Number | 135489-01 (internal barriers, 4x Prox/Accel) |

Key Features and Advantages

Application Areas

- Power Generation: Monitoring steam turbines and generators for vibration and displacement to prevent catastrophic failures. Its compliance with API 670 standards ensures adherence to oil and gas industry requirements.

- Petrochemical: Protecting compressors and pumps by detecting misalignment or bearing wear in real time. The external termination design simplifies wiring in hazardous zones where panel access is limited.

- Manufacturing: Ensuring precision in high-speed motors and gearboxes, critical for quality control in automotive and packaging industries. The module’s high-speed data acquisition supports advanced CNC machinery and robotics.

- Marine and Offshore: Safeguarding propulsion systems and offshore platforms with its rugged design and compliance with DNV and Class NK certifications.

Related Products

3500/40M 176449-01+125680-01 Bently Nevada

176449-01 3500/40M Bently Nevada Proximitor Monitor

3500/40-01-00 | Bently Nevada Proximitor Monitor

Bently Nevada 3500/40-01-00 125680-01 Proximitor I/O

Bently Nevada 3500/40 3500/40M 176449-01 140734

Installation and Maintenance

Ensure the 3500 Series rack is grounded and powered. Use the 3500 Rack Configuration Software to assign channel functions and configure communication protocols. For the BENTLY 3500/42-04-00, connect field wires directly to the external terminals, following torque specifications (±0.1 N·m) to avoid signal degradation. Verify compatibility with BENTLY 3300XL Proximity Transducers and secure cable routing to prevent electromagnetic interference.

- Calibration: Perform annual calibration using BENTLY TK-3E equipment to maintain accuracy. Calibration should include verifying sensor linearity and signal conditioning parameters.

- Inspection: Regularly check external connections for looseness or corrosion. Clean dust and debris from the module’s vents to prevent overheating, especially in high-dust environments.

- Firmware Updates: Periodically update software to access new features and bug fixes, ensuring compatibility with the latest 3500 Rack Configuration Software versions.

Product Warranty

- HS:7326909000

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com