Description

Many products are not yet available—feel free to contact us for more options.

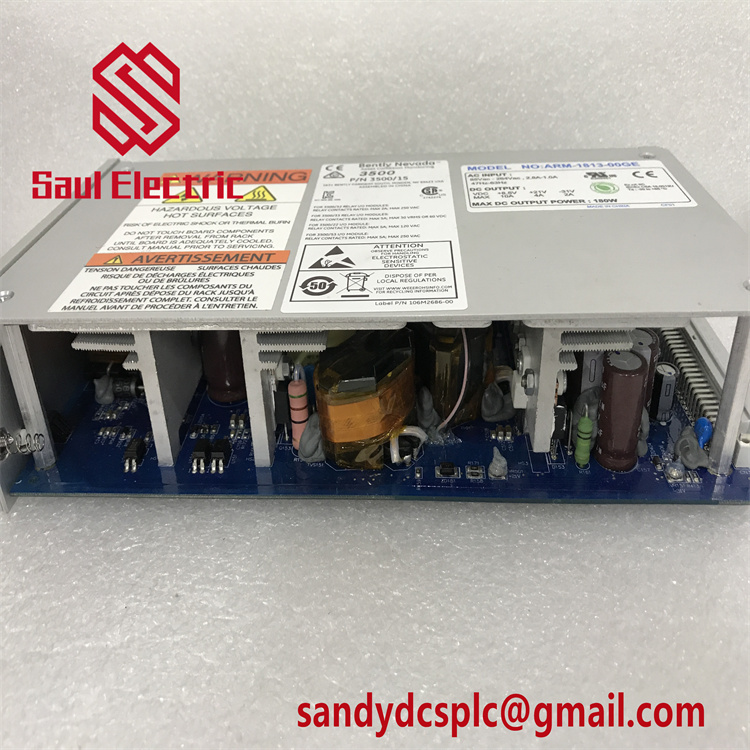

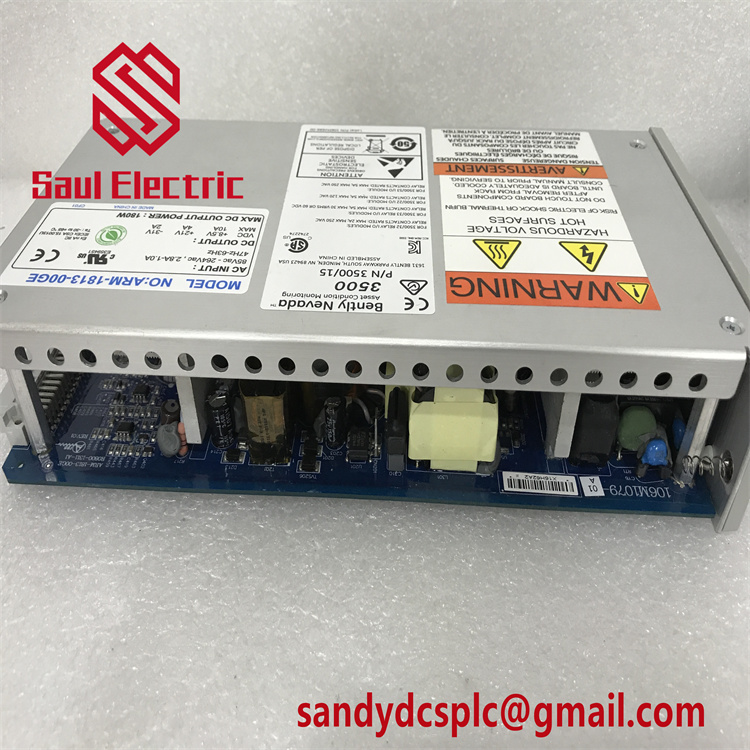

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The BENTLY Nevada 3500/40M 125680-01 is a 4-channel Proximitor I/O Module designed for high-precision vibration and position monitoring of rotating machinery. As a critical component of the 3500 Series Machinery Protection System, this module interfaces with BENTLY Nevada proximity sensors (e.g., 3300 XL series) to provide real-time measurements of radial vibration, axial displacement, differential expansion, and eccentricity. Engineered for compliance with API 670 standards, the 3500/40M 125680-01 ensures reliable operation in oil & gas, power generation, and industrial automation environments where machinery health is mission-critical.

Featuring epoxy-sealed construction and galvanic isolation, the module withstands harsh conditions (e.g., EMI, high vibration) while delivering ±0.33% full-scale accuracy for vibration measurements. Its programmable alarm setpoints (via 3500 Rack Configuration Software) enable automatic actuation of shutdowns or alarms through connected relay modules (e.g., 3500/34), ensuring fail-safe protection. The hot-swappable design minimizes downtime during maintenance, while front-panel LEDs provide instant status feedback (green for normal operation, red for faults).

In automation architectures, the 3500/40M 125680-01 acts as a vital interface between sensors and control systems, converting raw sensor data into actionable insights. By integrating with BENTLY Nevada’s System 1 software, it supports predictive maintenance strategies, reducing unplanned outages and extending equipment lifespan.

Technical Specifications

| Parameter | Value |

|---|---|

| Product Model | 3500/40M 125680-01 |

| Manufacturer | BENTLY Nevada |

| Product Type | Proximitor I/O Module (Internal Terminations) |

| Input Channels | 4 differential inputs (10kΩ impedance) |

| Sensor Compatibility | BENTLY Nevada 3300 XL proximity probes, 330500 velocity sensors |

| Measurement Parameters | Radial vibration, axial displacement, differential expansion, eccentricity |

| Sensitivity | 3.94 mV/μm (100 mV/mil) or 7.87 mV/μm (200 mV/mil) |

| Frequency Response | 0.1 Hz to 10 kHz |

| Outputs | 4-20 mA analog signals, RS-485 Modbus RTU |

| Power Supply | 24 VDC ±10% (7 W typical) |

| Operating Temperature | -40°C to +85°C (-40°F to +185°F) |

| Physical Dimensions | 241.3 mm x 24.4 mm x 241.8 mm (9.50″ x 0.96″ x 9.52″) |

| Weight | 0.91 kg (2.0 lb) |

| Isolation Voltage | 1000 VDC (input/output to ground) |

| LED Indicators | Power (green), TX/RX (flashing), Channel Fault (red per channel) |

| Certifications | CE, RoHS, API 670 compliant |

| Mounting | Rack-mounted in 3500 Series enclosure |

Key Features and Advantages

Multi-Channel I/O Capability: The 3500/40M 125680-01 supports 4 independent channels, each configurable for different measurement modes (e.g., radial vibration, REBAM® for bearing analysis). This allows simultaneous monitoring of multiple parameters without requiring additional modules.

Internal Termination Design: Unlike external termination blocks, this module features factory-installed internal terminations, simplifying wiring and reducing installation complexity. It includes screw terminals for direct sensor connections, ensuring secure and reliable signal integrity.

High Accuracy and Stability: With ±0.33% full-scale accuracy and 10,000-hour MTBF, the module ensures precise long-term performance. Its adaptive filtering reduces noise interference, enhancing signal integrity in high-vibration environments.

Programmable Logic Flexibility: The 3500 Rack Configuration Software enables user-defined alarm logic (e.g., 2-out-of-3 voting for critical channels) and configurable deadbands. Each channel can be assigned normally energized (NE) or normally de-energized (NDE) relay outputs, aligning with diverse control requirements.

Robust Environmental Resilience: The IP67-rated enclosure and arc-suppression circuitry protect against moisture, dust, and electrical transients. The module’s 10,000-cycle contact life reduces maintenance costs compared to mechanical relays.

Seamless Integration: Compatible with 3500/92 Communication Gateway, the 3500/40M 125680-01 supports Modbus RTU/TCP connectivity to PLCs and SCADA systems. It also interfaces with BENTLY Nevada’s 3500/22M Transient Data Interface for high-speed waveform analysis.

Application Areas

The BENTLY Nevada 3500/40M 125680-01 excels in applications requiring continuous machinery health monitoring:

- Oil & Gas: Monitoring compressor turbine shaft vibration and axial thrust in offshore platforms and refineries.

- Power Generation: Detecting rotor eccentricity in steam turbines and generator misalignment in power plants.

- Industrial Manufacturing: Ensuring precision in extruders, centrifuges, and ball mills by measuring radial vibration thresholds.

- Aerospace: Validating engine balance during testing by analyzing differential expansion data.

- Nuclear Energy: Providing real-time displacement measurements for reactor coolant pumps, critical for safety compliance.

By converting sensor data into actionable insights, the 3500/40M 125680-01 empowers predictive maintenance strategies, reducing repair costs by up to 30% in case studies.

Related Products

- 3500/34-10-00 125704-01: A TMR relay module for fail-safe actuation of alarms and shutdowns, compatible with the 3500/40M 125680-01.

- 3500/92 Communication Gateway: Enables Modbus RTU/TCP connectivity between the 3500/40M 125680-01 and external control systems.

- 330130 Proximity Probe: A sensor compatible with the 3500/40M 125680-01, delivering shaft position data for vibration analysis.

- 3500/15 Power Supply: Provides redundant power to the 3500 rack, ensuring continuous operation of the 3500/40M 125680-01.

- 176449-01 Proximitor Monitor: The companion monitor module for the 125680-01 I/O module, processing signals for real-time analysis.

Installation and Maintenance

Pre-Installation Preparation:

- Power off the 3500 rack and verify grounding.

- Use 3500 Rack Configuration Software to assign slot addresses and program alarm setpoints.

- Mount the 3500/40M 125680-01 in any slot to the right of the rack interface module, ensuring secure alignment with backplane connectors.

- Terminate sensor wiring directly to the module’s internal screw terminals, following polarity guidelines for -24 VDC power and signal inputs.

Maintenance Recommendations:

- Calibration: Recalibrate annually using BENTLY’s 3500 Test Utilities to maintain ±0.33% accuracy.

- Hot-Swap Procedure: Depress the front-panel release latch and remove the module while the system is running; replace with a spare to minimize downtime.

- Environmental Checks: Clean dust from vents quarterly to prevent overheating, and inspect LEDs monthly for fault indicators.

Product Warranty and Support

The BENTLY Nevada 3500/40M 125680-01 is backed by a 1-year warranty, covering defects in materials and workmanship. BENTLY’s global support network provides 24/7 technical assistance for configuration, troubleshooting, and firmware updates. With spot inventory in Hong Kong and mainland China and a 3-day delivery time after payment, customers benefit from rapid deployment and reduced project delays. This commitment to quality ensures seamless integration and long-term performance in mission-critical industrial environments.

HS:7326909000

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com