Description

BENTLY 3500/05-01-01-00-00-01

Product Overview

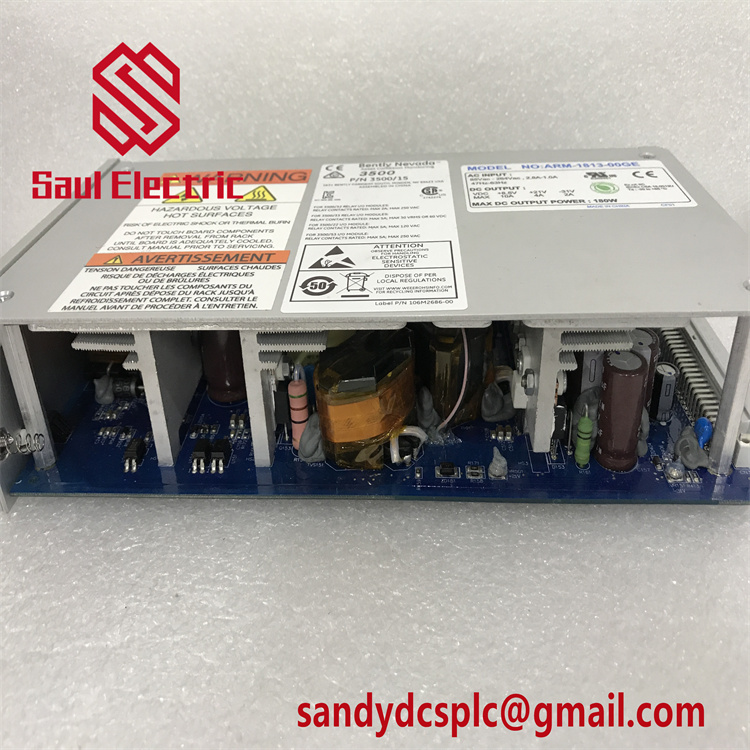

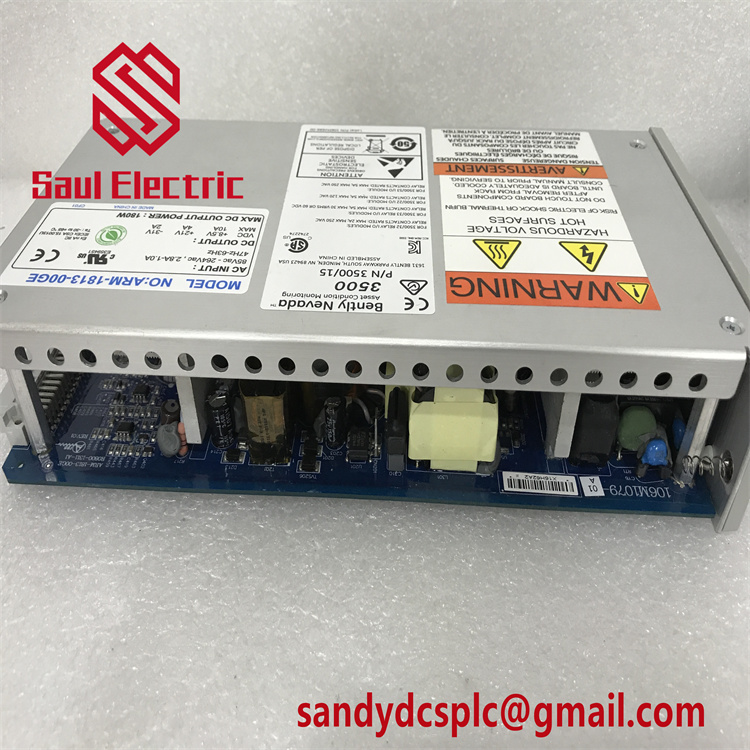

The BENTLY 3500/05-01-01-00-00-01 is a high-performance 19-inch System Rack engineered for critical machinery condition monitoring and protection systems. As the core platform of Bently Nevada’s 3500 series, this rack provides a rugged and scalable foundation for integrating vibration, displacement, speed, and temperature monitoring modules, ensuring seamless operation in industries such as oil & gas, power generation, and chemical processing. Designed to meet API 670 standards for machinery protection systems, the BENTLY 3500/05-01-01-00-00-01 supports up to 14 modular slots, allowing users to configure custom solutions for turbine, compressor, and pump monitoring applications.

Featuring a redundant power architecture (compatible with dual BENTLY 3500/15 power modules) and hot-swap capabilities, the rack ensures continuous operation even during maintenance. Its -40°C to +85°C operating temperature range and IP54-rated enclosure make it suitable for harsh environments, including offshore platforms and hazardous zones. The rack’s built-in RS-422/485 and Ethernet TCP/IP interfaces (via optional BENTLY 3500/22M interface modules) enable real-time data exchange with control systems and Bently’s System 1® software, facilitating predictive maintenance and remote diagnostics.

Compliant with SIL3 (IEC 61508) and ATEX/IECEx certifications, the BENTLY 3500/05-01-01-00-00-01 guarantees safety-critical performance in applications requiring fail-safe operation. Its modular design also supports triple modular redundancy (TMR) configurations for mission-critical assets, minimizing downtime and enhancing system resilience.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | BENTLY 3500/05-01-01-00-00-01 |

| Manufacturer | Bently Nevada |

| Product Type | 19-inch System Rack for Machinery Monitoring |

| Module Slots | 14 (expandable with compatible I/O modules) |

| Power Requirements | 24VDC (±10% tolerance) with dual redundancy support |

| Communication Protocols | RS-422/485, Ethernet TCP/IP (via BENTLY 3500/22M interface module) |

| Operating Temperature | -40°C to +85°C |

| Dimensions | 483 x 597 x 260 mm (19 x 23.5 x 10.25 inches) |

| Weight | 4.5 kg |

| Safety Certifications | SIL3 (IEC 61508), ATEX/IECEx (Zone 2), CE |

| Environmental Rating | IP54 (dust and water splash protection) |

| Redundancy Support | Dual power supply and TMR module configurations |

| Mounting Options | 19-inch EIA rack mount with rear-accessible wiring |

Key Features and Advantages

Modular Scalability: The BENTLY 3500/05-01-01-00-00-01 accommodates a wide range of Bently Nevada modules, including 3500/42M vibration monitors, 3500/53 overspeed detectors, and 3500/33 relay modules, enabling tailored solutions for specific machinery types. Its open architecture supports integration with third-party sensors and control systems, ensuring compatibility with legacy and modern automation setups.

Rugged Reliability: Built with industrial-grade materials, the rack withstands extreme temperatures, vibrations, and electromagnetic interference (EMI). Its redundant power design ensures uninterrupted operation, while galvanic isolation between modules protects against voltage spikes and ground loops.

Advanced Diagnostics: The rack’s built-in health monitoring system provides real-time status updates on module functionality, power supply integrity, and communication links. Faults are logged and transmitted to connected systems via configurable alarm outputs, allowing proactive maintenance and reducing mean time to repair (MTTR).

Compliance and Safety: With SIL3 certification and ATEX/IECEx approvals, the BENTLY 3500/05-01-01-00-00-01 meets the highest safety standards for hazardous environments. It also supports TMR configurations for applications requiring fault tolerance, such as emergency shutdown (ESD) systems in petrochemical plants.

Ease of Integration: The rack’s plug-and-play design simplifies installation, while Bently’s 3500 Rack Configuration Software streamlines module setup and parameter tuning. Its Ethernet connectivity enables seamless integration with plant-wide SCADA systems, enhancing operational visibility and control.

Applications

The BENTLY 3500/05-01-01-00-00-01 is widely deployed in industries requiring precision machinery monitoring:

- Oil & Gas: Monitoring compressors, pumps, and turbines in offshore platforms and refineries to prevent catastrophic failures.

- Power Generation: Protecting steam turbines and generators in thermal and nuclear power plants through real-time vibration analysis.

- Chemical Processing: Ensuring safe operation of agitators, extruders, and centrifuges by detecting mechanical imbalances and bearing wear.

- Mining: Safeguarding conveyor belts, crushers, and ventilation systems in underground mines with continuous condition monitoring.

- Metallurgy: Optimizing rolling mills and smelters by tracking shaft misalignment and gearbox health.

For example, in a petrochemical plant, the BENTLY 3500/05-01-01-00-00-01 might host 3500/42M vibration modules to monitor compressor bearings, triggering alarms or shutdowns if vibration levels exceed predefined thresholds.

Related Products

- BENTLY 3500/15-01-01-00: Redundant 24VDC power supply module for dual-power configurations.

- BENTLY 3500/22M-01-01-00: Ethernet interface module enabling TCP/IP communication and System 1® integration.

- BENTLY 3500/33-01-01-00: 16-channel relay module for alarm and shutdown outputs.

- BENTLY 3500/42M-01-01-00: Multifunction vibration/speed/acceleration monitor for rotating machinery.

- BENTLY 3500/53-01-01-00: Overspeed detection module with SIL3 compliance.

- BENTLY 3500/63-01-01-00: Modbus TCP/IP gateway for integrating with DCS/PLC systems.

- BENTLY 3500/93-01-01-00: Piezoelectric accelerometer module for high-frequency vibration analysis.

- BENTLY 3500/45-01-01-00: Axial position/differential expansion monitor for turbines.

- BENTLY 3500/60-01-01-00: Temperature monitor supporting RTD and thermocouple inputs.

- BENTLY 3500/25-01-01-00: Keyphasor® module for rotational speed and phase measurement.

These products complement the BENTLY 3500/05-01-01-00-00-01 by offering specialized monitoring and control capabilities, enabling comprehensive machinery protection systems.

Installation and Maintenance

Pre-Installation Preparation:

- Verify rack compatibility with Bently Nevada modules and third-party devices.

- Ensure proper grounding and surge protection for power and signal cables.

- Configure BENTLY 3500/22M interface module settings (IP address, baud rate) using the 3500 Rack Configuration Software.

- Mount the rack securely in a 19-inch enclosure with adequate ventilation (minimum 50mm clearance on all sides).

Maintenance Recommendations:

- Monthly Inspections: Clean dust from vents and verify module LED status indicators.

- Quarterly Testing: Perform functional tests on relays and communication links using Bently’s diagnostic tools.

- Annual Calibration: Recalibrate sensors and modules to maintain measurement accuracy.

- Firmware Updates: Regularly update module firmware to access new features and security patches.

- Spare Parts Inventory: Stock critical components like BENTLY 3500/15 power modules and BENTLY 3500/22M interface modules for rapid replacement.

Product Warranty and Support

The BENTLY 3500/05-01-01-00-00-01 comes with a 1-year warranty covering defects in materials and workmanship. Bently Nevada’s global support network provides 24/7 technical assistance, including remote diagnostics, firmware updates, and troubleshooting guidance. For mission-critical applications, expedited replacement services are available to minimize downtime. All racks undergo rigorous testing to meet ISO 9001 standards, ensuring long-term reliability in the most demanding industrial environments.

Contact info

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com