Description

Many products are not yet available—feel free to contact us for more options.

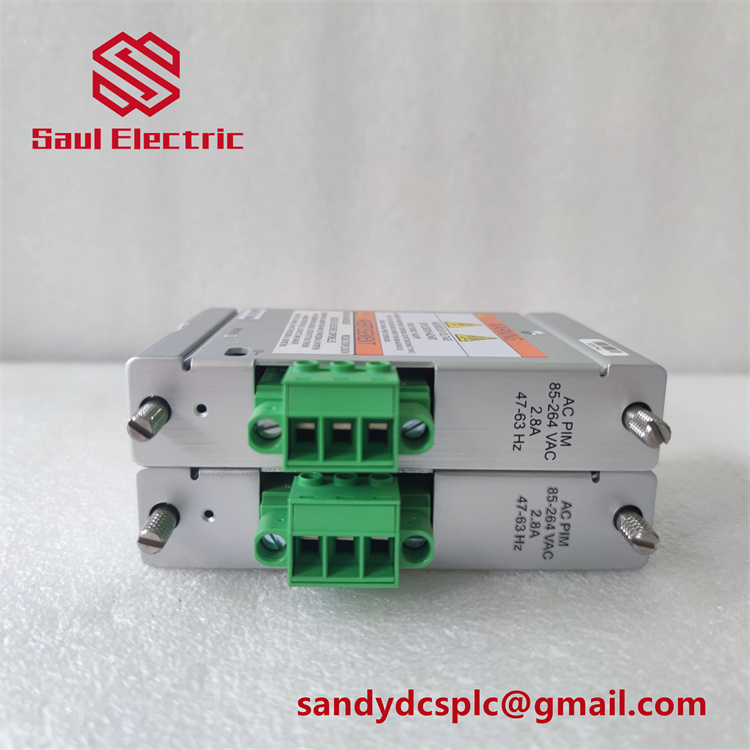

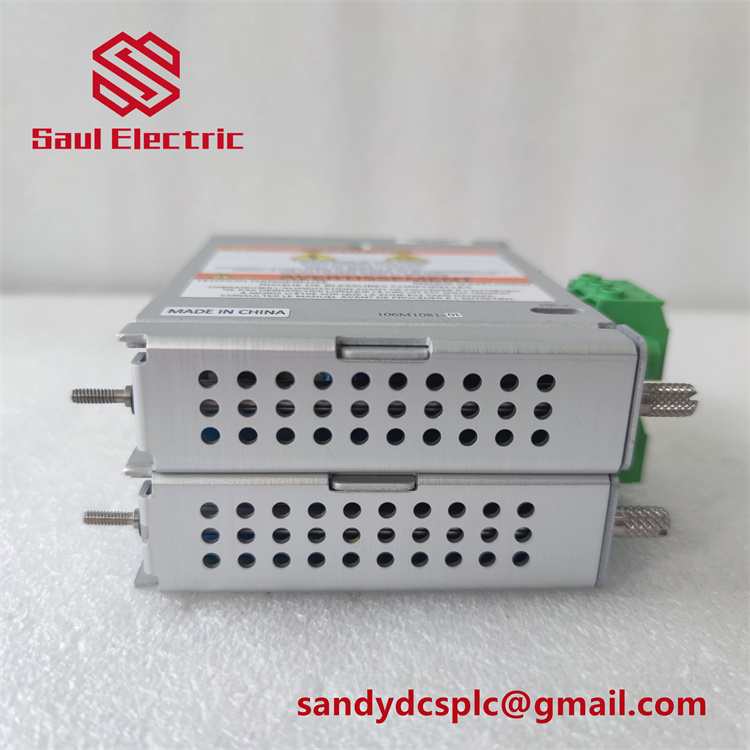

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The BENTLY 330104-00-05-10-02-00 is an 8mm eddy-current proximity probe from Bently Nevada’s 3300 XL series, designed for high-precision vibration and displacement monitoring in industrial rotating machinery. It operates by generating oscillating electromagnetic fields that interact with conductive surfaces, converting gap changes into standardized voltage outputs (-1 to -17 Vdc) for real-time detection of radial vibration, axial displacement, and keyphasor signals. Engineered for harsh environments, this probe features a stainless steel housing with IP67/NEMA 4X-rated sealing, ensuring resistance to moisture, dust, and chemicals. Its plug-and-play design allows full interchangeability with 3300 XL extension cables and proximitor modules without recalibration, significantly reducing maintenance complexity. Compliant with API 670 4th Edition standards, it integrates seamlessly with monitoring systems like Bently’s 3500 series for predictive maintenance in critical infrastructure such as turbines, compressors, and pumps.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 330104-00-05-10-02-00 |

| Manufacturer | Bently Nevada (GE Industrial Solutions) |

| Product Type | Eddy-Current Proximity Probe |

| Thread Size | M10×1 (Metric) |

| Cable Length | 5 meters (standard) |

| Linear Range | 2 mm (80 mils) |

| Sensitivity | 7.87 V/mm (200 mV/mil) ±5% |

| Operating Temperature | -40°C to +85°C (ambient); -51°C to +177°C (probe tip) |

| Frequency Response | 0.5 Hz – 10 kHz (±3 dB) |

| Connection Type | ClickLoc® Gold-Plated Connector |

| Enclosure Rating | IP67 / NEMA 4X |

| Compliance Standards | API 670 4th Edition, ATEX/IECEx (optional) |

| Output Signal | -1 Vdc to -17 Vdc (voltage) |

Key Features and Benefits

Precision and Interchangeability: The BENTLY 330104-00-05-10-02-00 delivers ±1% accuracy across its 2mm linear range, critical for detecting micro-scale mechanical anomalies like bearing wear or shaft misalignment. Its components (probes, cables, proximitors) are fully interchangeable within the 3300 XL series, eliminating bench calibration and expediting replacements.

Robust Construction: The stainless steel housing and ClickLoc® connectors withstand high-pressure washdowns, oil immersion, and electromagnetic interference (EMI). The IP67 rating ensures reliability in offshore platforms and refineries, while optional FluidLoc cables prevent fluid ingress in submerged applications.

Ease of Installation: Finger-tightened connectors (“click” mechanism) simplify mounting, with M10×1 threading compatible with standard industrial fixtures. Integrated locknuts prevent loosening under vibration, reducing mechanical failure risks.

Diagnostic Compatibility: Outputs dynamic vibration and gap voltage signals for real-time diagnostics via 3500/42M or 3500/50 monitor modules, enabling early alerts for imbalance or rubbing conditions.

Application Areas

The BENTLY 330104-00-05-10-02-00 is deployed in high-stakes industrial sectors:

- Power Generation: Monitors steam/gas turbine shaft vibrations and rotor imbalances to prevent blade failures, with low-frequency response (0.5 Hz) suited for hydroelectric generators.

- Oil & Gas: Safeguards centrifugal compressors in pipelines by detecting bearing degradation; high-temperature tolerance (177°C) supports gas turbine exhaust zones.

- Heavy Manufacturing: Tracks gearbox vibrations in steel mills and paper machine rollers, enabling maintenance during production pauses.

- Aerospace Testing: Validates engine rotor dynamics in test rigs via 10 kHz frequency response for high-RPM validation.

Related Products

3500/40M 176449-01+125680-01 Bently Nevada

176449-01 3500/40M Bently Nevada Proximitor Monitor

3500/40-01-00 | Bently Nevada Proximitor Monitor

Bently Nevada 3500/40-01-00 125680-01 Proximitor I/O

Bently Nevada 3500/40 3500/40M 176449-01 140734

Installation and Maintenance

Installation Preparation: Mount the probe perpendicular to the target surface (e.g., shaft) with a 1.5–2mm gap for steel. Use shielded triaxial cables (≤305m) to minimize EMI, and ensure probe-cable lengths match (e.g., 5m probe with 5m extension) to prevent signal drift.

Maintenance Recommendations: Bi-annually inspect probe resistance (target: 7–8Ω) and clean oil/grease buildup with non-abrasive solvents. Verify linearity using TK-3E calibration tools; replace if output deviation exceeds ±5%.

Product Assurance

The BENTLY 330104-00-05-10-02-00 includes a 12-month warranty covering manufacturing defects. Global technical support covers installation guidance and field diagnostics. Units undergo ISO 9001-certified testing, with lifetime firmware updates for compatible monitoring systems.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com