Description

Many products are not yet available—feel free to contact us for more options.

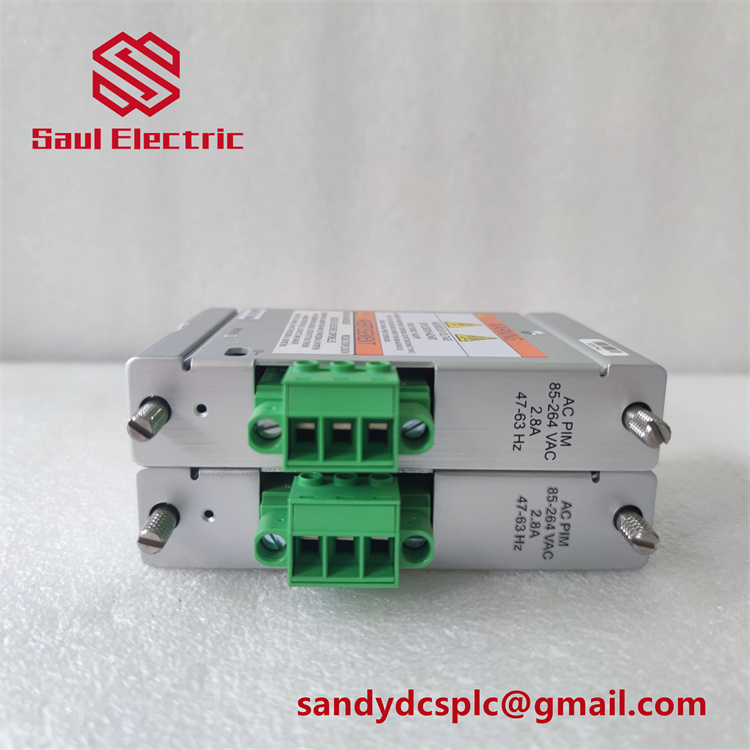

If there is a discrepancy between the product model and the displayed image, the model shall take precedence. For specific product photos, please reach out to us, and we will arrange on-site warehouse shots to confirm details.

With an extensive global warehouse network, there may be occasions where it takes a few hours to provide an accurate response. We appreciate your understanding, and rest assured we’ll address your inquiries as promptly as possible.

Product Overview

The BENTLY 330100-90-01 is a high-precision vibration transmitter module engineered for industrial machinery health monitoring, forming a critical component of Bently Nevada’s 3300 Series. This module converts mechanical vibration signals from proximity probes into standardized 4–20 mA outputs, enabling real-time tracking of shaft vibration, displacement, and position in rotating equipment. Designed for seamless integration with DCS, PLC, or SCADA systems, it provides actionable data to detect early signs of wear, misalignment, or imbalance, thereby preventing catastrophic failures and minimizing downtime.

As a data bridge in automation setups, the BENTLY 330100-90-01 ensures signal accuracy and reliability in harsh environments, with compliance to industrial standards like API 670. Its rugged IP66/NEMA 4X-rated enclosure supports deployment in extreme conditions, from offshore platforms to high-temperature industrial sites, enhancing operational safety and equipment longevity. The module’s dual-channel input and loop-powered design simplify installation while maintaining measurement integrity, making it indispensable for predictive maintenance strategies.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 330100-90-01 |

| Manufacturer | Bently Nevada |

| Product Type | Vibration Transmitter Module |

| Input Channels | 2 (Proximity Probes) |

| Output Signal | 4–20 mA (Linear, Isolated) |

| Power Supply | 18–30 VDC (Loop-Powered) |

| Operating Temperature | -40°C to +85°C |

| Frequency Response | 0.5 Hz – 10 kHz (±3 dB) |

| Dynamic Range | 80 dB |

| Housing Material | Stainless Steel 316L |

| Enclosure Rating | IP66 (NEMA 4X) |

| Mounting Method | 2-Inch Pipe or Panel Mount |

| Communication Protocol | Modbus RTU |

| Dimensions | 4.5″ x 3.2″ x 2.8″ (114 x 81 x 71 mm) |

Key Features and Benefits

High Precision and Stability: The BENTLY 330100-90-01 leverages advanced DSP algorithms to deliver ±1% full-scale accuracy in vibration measurement. Its wide frequency response (0.5 Hz–10 kHz) captures both low-speed anomalies and high-frequency defects (e.g., bearing wear or rotor imbalances), enabling early fault detection. The module’s auto-calibration maintains accuracy across temperature fluctuations (-40°C to +85°C), critical for turbines and compressors.

Robust Design for Harsh Environments: Featuring an IP66/NEMA 4X stainless steel enclosure, the module resists dust, water, and corrosive substances. It operates reliably in extreme settings like oil rigs or desert facilities, with EMI/RFI shielding ensuring signal integrity even near high-power equipment.

Ease of Integration and Diagnostics: Loop-powered operation eliminates external power supplies, reducing wiring complexity. The 4–20 mA output interfaces directly with industrial control systems, while self-diagnostic alerts identify sensor failures or communication errors. Configurable output scaling allows customization for specific machinery thresholds.

Compatibility and Scalability: Optimized for Bently Nevada’s ecosystem, including 3300 Series probes and System 1 software, the module supports centralized data analysis and predictive maintenance workflows. Its dual-channel design simultaneously monitors velocity and acceleration, reducing hardware costs.

Application Areas

The BENTLY 330100-90-01 excels in critical machinery protection across industries:

- Power Generation: Monitors steam/gas turbine vibrations and rotor imbalances in thermal plants, preventing unplanned outages. In hydroelectric facilities, it tracks shaft oscillations in water turbines.

- Oil & Gas: Deployed in centrifugal compressors for vibration analysis and pipeline booster pumps to detect bearing degradation. Its high-temperature tolerance (up to 85°C ambient) suits refinery applications.

- Heavy Manufacturing: Ensures operational integrity in cement kiln drives, paper mill rollers, and high-speed fans by identifying misalignment or gear defects. Real-time alerts enable maintenance scheduling during planned downtime.

- Aerospace and Testing: Validates dynamic stability in engine test benches and aircraft component simulations, leveraging its 10 kHz frequency response for high-RPM monitoring.

Related Products

3500/40M 176449-01+125680-01 Bently Nevada

176449-01 3500/40M Bently Nevada Proximitor Monitor

3500/40-01-00 | Bently Nevada Proximitor Monitor

ABB PPD539A102 3BHE039770R0102

Bently Nevada 3500/40-01-00 125680-01 Proximitor I/O

Bently Nevada 3500/40 3500/40M 176449-01 140734

Installation and Maintenance

Installation Preparation: Verify power supply stability (18–30 VDC) and use shielded cables (max 305m length) to minimize interference. Mount the BENTLY 330100-90-01 via 2-inch pipe or panel, ensuring perpendicular alignment between probes and target surfaces (gap: 1.5–2mm for steel shafts).

Maintenance Recommendations: Perform bi-annual calibration with the TK-3E kit to validate output linearity. Regularly inspect probe resistance (target: 7–8Ω) and cable integrity; deviations may indicate contamination or physical damage. For environments with high vibration, secure cable connections to prevent fatigue failure.

Product Assurance

The BENTLY 330100-90-01 includes a 12-month warranty covering manufacturing defects. Technical support spans installation guidance, field debugging, and calibration training. All units undergo factory testing per ISO 9001, CE, and UL standards, ensuring compliance with industrial safety and performance requirements. Post-warranty repair services and lifetime access to firmware updates are available through authorized partners.

HS:8443919090

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com