Description

Product Overview

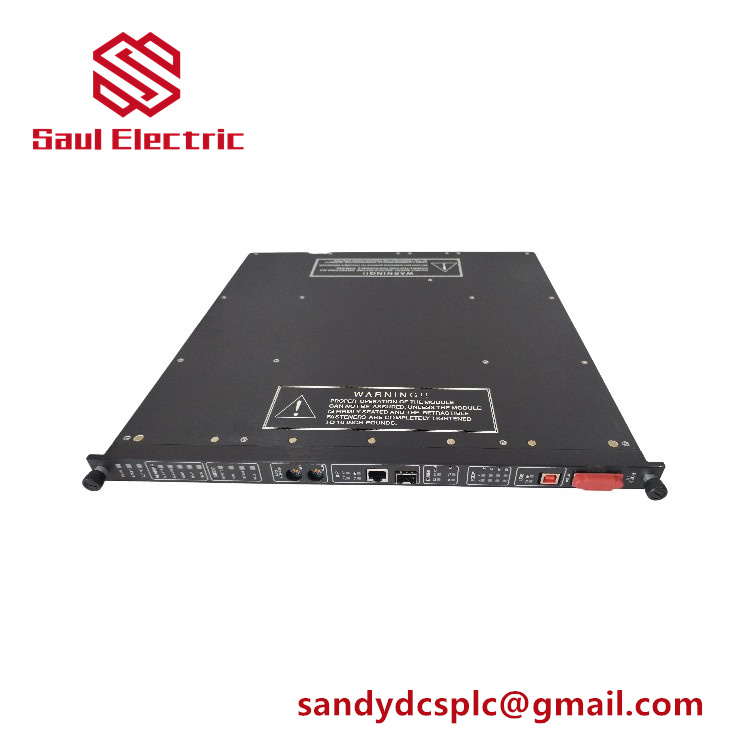

The TRICONEX 20064-320 is a high-integrity safety I/O module manufactured by TRICONEX (a Schneider Electric brand specializing in critical control systems). Designed for the Tricon V9/Tristation™ V9 safety platform, this module integrates Triple Modular Redundant (TMR) architecture to ensure fault-tolerant operation in safety-critical environments. As part of a Safety Instrumented System (SIS) or Emergency Shutdown (ESD) system, the TRICONEX 20064-320 processes digital or analog signals with ultra-reliability, enabling precise monitoring and control of field devices like sensors and actuators. Its core function is to bridge field equipment and the central TMR controller, executing safety logic while performing continuous self-diagnostics. The TRICONEX 20064-320 is certified for SIL 3 per IEC 61508/61511, making it ideal for industries where failure is not an option. It enhances system availability, reduces downtime through hot-swappable maintenance, and protects personnel, assets, and processes in harsh industrial conditions.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | TRICONEX 20064-320 |

| Manufacturer | TRICONEX (Schneider Electric) |

| Product Type | Safety I/O Module (Digital/Analog) |

| Input/Output Channels | 8-16 points (redundant) |

| Signal Type | 24V DC (digital) or 4-20mA (analog) |

| Resolution | 16-bit (analog variants) |

| Accuracy | ±0.05% full scale (analog) |

| Operating Temperature | -40°C to +70°C |

| Safety Certification | SIL 3 (IEC 61508/61511) |

| Communication | TMR I/O Bus |

| Diagnostics | Built-in self-test (BIST) |

| Isolation | 1500V AC channel-to-channel |

| Mounting | DIN rail or chassis slot |

| Weight | Approx. 0.5–1.0 kg |

Main Features and Advantages

Triple Modular Redundancy (TMR): The TRICONEX 20064-320 leverages three independent processing channels with hardware voting, ensuring continuous operation even if one channel fails. This design eliminates single points of failure, critical for applications like turbine control or reactor shutdown systems.

Advanced Diagnostics: Real-time health monitoring detects faults in field wiring, channel discrepancies, and internal errors, triggering alerts within milliseconds. This enables predictive maintenance and reduces unplanned downtime.

Hot-Swappable Design: Modules can be replaced without system shutdown, maximizing operational availability and simplifying maintenance in continuous processes like oil refining or power generation.

Environmental Robustness: With a conformal-coated PCB and wide operating temperature range (-40°C to +70°C), the module performs reliably in corrosive, humid, or high-vibration environments (e.g., offshore platforms).

HART Protocol Support (if analog): Facilitates bidirectional communication with smart field devices for calibration and diagnostics, reducing manual intervention.

Application Areas

The TRICONEX 20064-320 is deployed in SIL 3-certified safety loops across high-risk industries:

- Oil & Gas: Emergency Shutdown (ESD) systems for wellheads, pipelines, and refining units.

- Chemical/Petrochemical: Burner Management Systems (BMS) and fire & gas detection.

- Power Generation: Turbine overspeed protection and boiler safety interlocks.

- Pharmaceutical: Sterilization steam valve control in CIP/SIP processes.

- Water Treatment: Safety-critical pump and valve management in hazardous environments.

Related Products

HS:8538 9000.00

- WhatsApp: +86 18030182217

- Email: sandydcsplc@gmail.com

- Phone: +86 18030182217

- Wechat: +86 18030182217

- Website: www.xiongbaparts.com

+86 18030182217

+86 18030182217 +86 18030182217

+86 18030182217 sandydcsplc@gmail.com

sandydcsplc@gmail.com